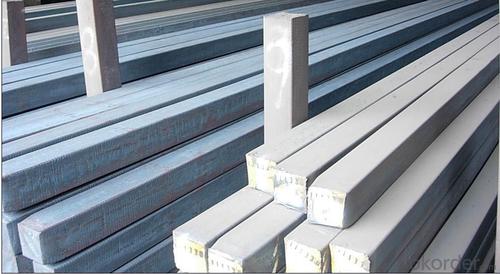

Q235/3SP 100MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 100MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 100MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 100MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 100MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 100MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: For example, screw plate (PU plate and manganese plate), carbon steel Primeton is what person rolling out?.

- Primeton Pu board generally refers to A3; carbon steel refers to the high quality carbon steel, such as No. 45 steel, 35 steel and so on; that in addition to the carbon and other elements, such as Cr, Mo etc., in which the carbon ratio below 30 for low alloy steel

- Q: Can steel billets be used for making musical instruments?

- Yes, steel billets can be used for making musical instruments. While traditional musical instruments are often made from materials such as wood or brass, steel can also be used to create unique and modern instruments. Steel's strength and durability make it ideal for certain instruments, such as steel drums or steel guitars. Additionally, steel's versatility allows for the creation of intricate designs and shapes that can produce a wide range of sounds. However, it is important to note that the specific characteristics and properties of the steel used, such as its composition and thickness, will greatly impact the sound and quality of the instrument. Therefore, careful consideration and experimentation may be required to achieve the desired musical tones and effects when using steel billets for instrument making.

- Q: How are steel billets used in the manufacturing of packaging equipment?

- Steel billets are an important component in the manufacturing of packaging equipment. These billets serve as the raw material for producing various parts and components of packaging machinery. Firstly, steel billets are typically used to fabricate the frames and structures of packaging equipment. The high strength and durability of steel make it an ideal choice for constructing the sturdy framework that supports the entire machine. This ensures that the packaging equipment can withstand the rigors of continuous operation and heavy loads. Additionally, steel billets are also used to manufacture key components such as gears, shafts, and rollers. These components are essential for the proper functioning of packaging machinery, enabling the movement and rotation required for packaging products efficiently. Steel's excellent mechanical properties, including high tensile strength and resistance to wear and tear, make it suitable for these critical parts. Moreover, steel billets are often utilized in the production of cutting and forming tools used in packaging equipment. These tools are responsible for shaping and cutting various materials, such as cardboard or plastic, to create packaging containers or wrap products. Steel's hardness and ability to retain sharp edges make it an ideal material for crafting these tools, ensuring precise and efficient packaging operations. In summary, steel billets are integral to the manufacturing of packaging equipment as they are used to create the frames, components, and tools necessary for the efficient and reliable operation of packaging machinery. Their strength, durability, and versatility make steel billets a preferred choice in the packaging industry.

- Q: How are steel billets used in the manufacturing of renewable energy equipment?

- The production of renewable energy equipment relies heavily on steel billets. These billets are melted and molded into specific shapes, usually square or rectangular, using a process called casting. Once formed, they undergo further processing and shaping to create the required components. In wind energy, for example, steel billets are used to manufacture the sturdy tower structures that support the wind turbines. These towers must be able to withstand harsh environmental conditions and support the turbine's weight. Steel billets provide the necessary strength and durability to construct these towers, ensuring the longevity and reliability of the turbines. Likewise, in solar energy, steel billets are used in the production of solar panels and mounting structures. Steel frames are necessary to support the photovoltaic cells and shield them from external factors. Additionally, steel billets are used to build the mounting structures that secure the solar panels in place, allowing them to efficiently capture sunlight. Steel billets are also integral to hydroelectric power equipment. They are utilized in the construction of turbines and other components that are submerged in water. These billets require excellent corrosion resistance and high strength to withstand the extreme conditions and forces present in hydroelectric power plants. Moreover, steel billets find applications in the manufacturing of components for other types of renewable energy equipment, such as geothermal power plants and biomass energy systems. They are used in various ways, including as structural supports, heat exchangers, and boilers, where their strength and durability are of utmost importance. In conclusion, steel billets play a crucial role in the production of renewable energy equipment. Their strength, durability, and corrosion resistance make them an ideal material for constructing the essential components of wind turbines, solar panels, hydroelectric power plants, and other renewable energy systems. By providing the necessary structural integrity, steel billets contribute to the efficient and reliable operation of renewable energy equipment, facilitating the transition to a more sustainable and eco-friendly energy future.

- Q: What is the typical size and shape of steel billets?

- Steel billets typically have a rectangular or square shape and come in various sizes. The most common sizes range from 100mm x 100mm to 300mm x 300mm, with lengths typically ranging from 3 meters to 12 meters. However, the size and shape of steel billets can vary depending on the specific requirements of the steel production process and the intended use of the billets.

- Q: What are the main factors affecting the hardenability of steel billets?

- The hardenability of steel billets, which refers to their ability to be hardened through heat treatment, is influenced by several key factors. These factors include the chemical composition of the steel, the rate at which it is cooled during quenching, and the size of its grains. First and foremost, the chemical composition of the steel plays a vital role in determining its hardenability. Elements like carbon, manganese, and alloying elements such as chromium, molybdenum, and nickel can have a significant impact on the steel's ability to be hardened. Higher carbon content and the presence of certain alloying elements increase the hardenability by forming carbides that aid in the formation of martensite, the hard and brittle phase responsible for the steel's hardness. The rate at which the steel is cooled during quenching is another crucial factor affecting its hardenability. Quenching involves rapidly cooling the heated steel billet, typically using a liquid medium like water or oil. The speed of cooling determines the transformation of the steel's microstructure. Faster cooling rates result in higher hardenability as they promote the formation of martensite. Conversely, slower cooling rates can lead to the formation of softer phases like ferrite or pearlite. The size of the steel's grains also impacts its hardenability. Smaller grain sizes provide more sites for the formation of martensite, resulting in improved hardenability. Grain refinement can be achieved through processes like alloying, heat treatment, and controlled cooling. Additionally, the presence of non-metallic inclusions, which act as areas of stress concentration, can also affect hardenability by promoting crack initiation and propagation during quenching. In conclusion, the main factors that influence the hardenability of steel billets are the chemical composition, cooling rate during quenching, and grain size. Understanding these factors and their interactions is crucial for achieving the desired hardness and mechanical properties in steel billets during heat treatment processes.

- Q: Can steel billets be used in the production of pipes?

- Yes, steel billets can be used in the production of pipes. Steel billets are the raw material for the manufacturing of various steel products, including pipes. The process involves heating the steel billets to a high temperature and then shaping them into pipes through different methods such as hot rolling, cold rolling, or extrusion. Steel billets provide the necessary strength, durability, and uniformity required for the production of pipes. Additionally, they can be further processed and treated to meet specific requirements such as corrosion resistance or enhanced mechanical properties. Therefore, steel billets play a vital role in the production of pipes and are widely used in the steel industry for this purpose.

- Q: How are steel billets used in the manufacturing of electrical transmission equipment?

- Steel billets are used in the manufacturing of electrical transmission equipment as a key raw material. These billets are essentially solid blocks of steel that undergo further processing to transform them into various components required for electrical transmission equipment. One of the main uses of steel billets in this context is for the production of transmission towers. These towers provide the infrastructure needed to support power lines and ensure the safe and efficient transmission of electricity over long distances. Steel billets are used to manufacture the structural components of these towers, including the main vertical and horizontal members, as well as the cross arms and braces. Additionally, steel billets are also used in the manufacturing of conductors for electrical transmission equipment. Conductors are the cables that carry the electrical current between power generation stations and distribution networks. Steel billets are processed to create the necessary wires and strands that are then used to construct these conductors. The high strength and durability of steel make it an ideal material choice for these applications, as it can withstand the high tension and load requirements of electrical transmission systems. Furthermore, steel billets are used in the production of various other components used in electrical transmission equipment, such as pole line hardware, insulators, and connectors. These components are crucial for the proper functioning and reliability of the electrical transmission system, and steel billets provide the necessary strength and stability required for their construction. In summary, steel billets play a vital role in the manufacturing of electrical transmission equipment. They are used to produce transmission towers, conductors, and other essential components, ensuring the safe and efficient transmission of electricity across long distances.

- Q: What are the different surface defects that can be found in steel billets?

- There are several common surface defects that can be found in steel billets. These defects can occur during the manufacturing process or due to handling and transportation. Some of the different surface defects that can be found in steel billets include: 1. Scale: Scale is a type of surface oxidation that appears as a thin layer of iron oxide on the surface of the billet. It can occur during the heating and cooling process and can be removed through mechanical or chemical cleaning methods. 2. Cracks: Cracks can occur due to the improper cooling of the billet or excessive stress during handling. They can either be longitudinal or transverse, and their severity depends on the depth and length of the crack. Cracks can weaken the structural integrity of the billet and should be carefully inspected and repaired. 3. Inclusions: Inclusions are particles or impurities that are trapped within the steel during the manufacturing process. They can be non-metallic or metallic in nature and can affect the mechanical properties of the billet. Inclusions can be categorized as slag inclusions, gas porosity, or non-metallic inclusions like oxides and sulfides. 4. Decarburization: Decarburization is a surface defect that occurs due to the loss of carbon on the surface of the billet during the heating process. It can result in reduced hardness and strength of the steel in the affected area. Decarburization can be minimized by controlling the heating and cooling process and using protective atmospheres. 5. Laminations: Laminations are layers or sheets of non-metallic material that are trapped between the layers of steel during the manufacturing process. They can cause weak spots in the billet and can lead to failure under stress. Laminations can be detected through non-destructive testing methods and should be removed or repaired. 6. Pitting: Pitting is a localized corrosion phenomenon that appears as small pits or cavities on the surface of the billet. It can occur due to exposure to corrosive environments or improper storage conditions. Pitting can reduce the lifespan of the billet and should be treated to prevent further corrosion. It is important to note that these surface defects can vary in severity and impact the quality and performance of the steel billet. Regular inspection, testing, and quality control measures are necessary to identify and address these defects to ensure the integrity of the steel billet and the final products made from it.

- Q: How are steel billets used in the production of flanges?

- Flanges, which are vital components used to connect pipes, valves, and other equipment in industries such as oil and gas, petrochemicals, and power plants, require steel billets as their essential raw material. To manufacture flanges, steel billets are initially heated to a high temperature, making them malleable and easy to shape. Then, they go through a series of rolling mills where hot rolling or forging processes take place. These processes help shape the steel billets into the desired dimensions of the flanges, including outer diameter, inner diameter, and thickness. During the rolling or forging process, immense pressure is applied to the steel billets, aligning the steel grains and enhancing the structural integrity of the flanges. This ensures that the flanges can endure high pressures, temperature fluctuations, and other challenging operating conditions throughout their service life. Once the initial shaping is accomplished, additional processing is carried out to refine the surface finish of the flanges. This may involve machining, grinding, or polishing, depending on the specific design requirements of the flanges. These additional steps are essential to achieve a smooth and precise surface, ensuring proper sealing and connection when the flanges are installed in a piping system. After the surface finish is refined, the flanges undergo various quality control checks, including dimensional inspections, mechanical testing, and non-destructive testing. These tests guarantee that the flanges meet industry standards and specifications, assuring their reliability and performance. In conclusion, steel billets play a vital role in the production of flanges as they provide the necessary raw material for shaping and forming these essential components. The combination of high-temperature processing, rolling or forging, and subsequent finishing processes results in the creation of strong, durable flanges capable of withstanding demanding conditions in industrial applications.

Send your message to us

Q235/3SP 100MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords