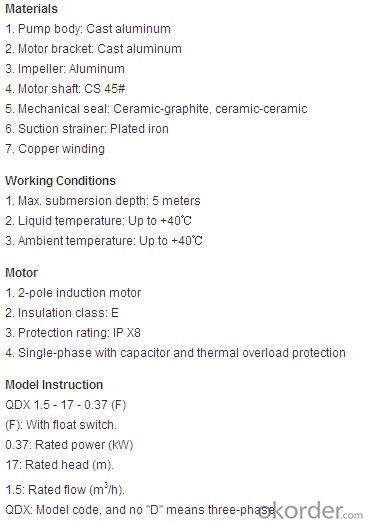

Q(D)X Submersible Pump for Clean Water

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: I cant get water to flow though the motor It seems like the pump isnt working any advise!

- You okorder /

- Q: Is the pump lift horizontal or vertical?

- A vertical, vertical lift is one meter (see environment), usually 5~10 times the horizontal distance

- Q: Difference between primary hot water pump and two hot water pump

- Primary pump variable flow VPF (variable primary)Flow) system is the new layout of central air-conditioning system, compared with the one or two pump system has more advantages in initial investment and operation cost. At present, some with a pump with variable flow system engineering in the operation of many problems,

- Q: 93 Cutless Sierra FWD

- It's a major job involving the belt tensioner and quite a few other hard to get at parts as the water pump is buried against the side of the engine compartment. But if you want to try it borrow from the library or buy a Chilton's or any popular service manual and follow the directions (STEP BY STEP),good luck

- Q: My water pump is sitting very close if not rubbing against the case. There were shavings and a groove. Would this cause it to knock? Also would this blow up the lower end? One more, Should it be in the center or offset twards the top?

- it won't spin whilst you evaluate that's quickly geared to the crankshaft. turn the crankshaft - it is going to then spin. you may no longer eliminate the water pump without eliminating the grab conceal. eliminate the water pump shaft's protecting clip, to eliminate the water pump.

- Q: And my heater works 80 % of the time, Is it still ok to drive if I keep putting water in it?

- most water pumps have a weep hole in the bottom of the pump when the seal goes its because the bearing is going bad. As long as the bearing keeps going you have a chance the problem is if the bearing freezes up it just goes BANG ! AND BLOWS ITSELF OFF THE CAR DAMAGING WHATEVER IT HITS ON THE WAY OUT. better safe than sorry a water pump is not that expensive compared to the damage it can cause if the fan locks and shatters too.

- Q: It is used in a water pumping station.

- It a waterproof pump that go underwater without shorting out. It uses an impeller to move the water. Some impellers look like a star and some look like the Impeller on a car water pump. There different designs depending on the amount of water the pump will pump.

- Q: could it be the water pump??

- sounds like a head gasket to me, I'd get it checked immediately.

- Q: How tight to a tighten down the bolts on a '86 volvo 240 water pump. The manual I bought doesn't say. The torque won't help me cause I don't have a torque wrench, so just general discription would help a lot. (I stripped the threads on a stud last time)

- Volvo Water Pump

- Q: I don't want to have to rent or purchase a electric pump to pump the water out of my pool so are there other ways to get the water out besides the obvious (a bucket and alot of people). I am really tight on money so purchasing a device to do the work isn't a real option but I really need to drain the pool without damaging it.

- On the off chance that you have a close area that is down hill from the bottom of the pool you could siphon it. Not a likely situation though. Siphoning is using a small hose, garden hose will probably be too big and sucking on the end of the hose to draw water though it. Once it starts flowing if the end is downhill from the bottom of the pool it will drain the pool all on its own.

Send your message to us

Q(D)X Submersible Pump for Clean Water

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords