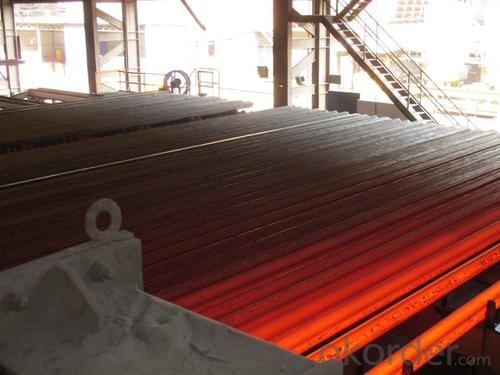

Prime square alloy steel billet 85mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 85mm Q235

Description of Prime square alloy steel billet 85mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime square alloy steel billet 85mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 85mm Q235

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime square alloy steel billet 85mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 85mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: Can steel billets be forged?

- Yes, steel billets can be forged.

- Q: What are the different methods of steel billet cutting and machining?

- There are several methods of cutting and machining steel billets, each with its own advantages and applications. Some of the most common methods include: 1. Sawing: This method involves using a saw blade to cut through the steel billet. It is a relatively simple and cost-effective method, suitable for cutting large quantities of billets into desired lengths. However, it may result in rough edges and require additional finishing processes. 2. Flame cutting: Also known as oxy-fuel cutting, this method uses a fuel gas combined with oxygen to create a high-temperature flame that melts and cuts through the steel billet. It is useful for cutting thick billets and can achieve a high level of precision. Flame cutting can be done manually or using automated machines. 3. Plasma cutting: This method employs a plasma torch to generate a high-velocity jet of ionized gas that melts and cuts through the steel billet. It is particularly effective for cutting through thick materials, as well as for intricate shapes and curves. Plasma cutting offers high cutting speeds and excellent precision. 4. Waterjet cutting: In this method, a high-pressure jet of water mixed with abrasive particles is used to cut through the steel billet. Waterjet cutting is versatile and can handle various materials, including steel, without generating heat-affected zones or causing distortion. It is ideal for cutting complex shapes and thin materials. 5. Laser cutting: Laser cutting involves using a high-powered laser beam to melt and vaporize the steel billet along a predefined path. This method offers exceptional precision and enables intricate and complex cuts. Laser cutting is commonly used for thin to medium thickness billets and is suitable for both small-scale and industrial applications. In addition to these cutting methods, there are various machining processes that can be applied to steel billets, such as milling, turning, drilling, and grinding. These processes involve removing material from the billet to achieve desired shapes, dimensions, and surface finishes. The choice of machining method depends on factors such as the complexity of the part, required tolerances, and production volume. Overall, the different methods of steel billet cutting and machining provide a range of options for manufacturers to effectively shape and process steel billets according to their specific requirements.

- Q: How are steel billets used in the manufacturing of construction cranes?

- Construction cranes rely on steel billets as a crucial component in their manufacturing process. These metal forms, which are partially finished, are typically shaped into rectangular or square forms using molten steel. Afterward, they undergo further processing to become various crane parts. A key application of steel billets in crane manufacturing is for producing structural elements. These billets are heated and rolled into long, slender beams or columns that form the crane's backbone. These beams provide the necessary strength and rigidity to support heavy loads and withstand the stresses during crane operation. By utilizing steel billets, manufacturers ensure the durability and load-bearing capacity of crane structures. Furthermore, steel billets are also used in manufacturing crane boom sections. The boom is the crane's extended arm, allowing it to reach high elevations and transport heavy materials. Steel billets are reheated and shaped into cylindrical or rectangular sections, which are then welded together to create an elongated boom structure. The use of steel billets ensures the necessary strength and stiffness for safely lifting and maneuvering heavy loads. Moreover, steel billets find application in manufacturing other crane components, including pulleys, gears, and fittings. These billets are forged, machined, or cast into the required shapes and sizes to form intricate parts that enable smooth and efficient crane operation. The strength and versatility of steel make it an ideal material for these critical components. In conclusion, steel billets have a vital role in crane manufacturing, providing raw material for producing structural elements, boom sections, and other crucial components. Their strength, durability, and versatility make them an excellent choice for constructing cranes capable of handling heavy loads and withstanding the demanding conditions of construction sites.

- Q: How do steel billets contribute to sustainable construction?

- Steel billets play a crucial role in sustainable construction through various means: 1. Energy efficiency: By utilizing electric arc furnaces, steel billets require less energy than traditional manufacturing methods. This leads to decreased greenhouse gas emissions and a reduced carbon footprint. 2. Recyclability: Steel billets can be recycled multiple times without losing their mechanical properties, making steel one of the most recycled materials worldwide. This conserves natural resources, reduces waste disposal, and lessens the need for new steel production. 3. Strength and durability: With their exceptional strength and durability, steel billets are an excellent choice for sustainable construction. Their structural integrity ensures long-lasting buildings, minimizing the need for frequent repairs or replacements and extending the lifespan of structures. 4. Versatility: Steel billets can be shaped and formed into various structural components, allowing for flexible design and construction. This adaptability enables the construction of sustainable buildings that can easily accommodate changing requirements, reducing the necessity for new construction. 5. Resilience to natural disasters: Steel billets exhibit outstanding resistance to seismic forces, hurricanes, and other natural disasters. This makes them ideal for constructing buildings in disaster-prone regions, thereby enhancing the safety and resilience of the built environment. 6. Reduced construction time: The prefabricated nature of steel billets enables faster construction, minimizing disruption to the environment and local communities. Additionally, prefabricated steel components can be easily dismantled and reused, further enhancing sustainability. In conclusion, steel billets contribute significantly to sustainable construction by reducing energy consumption, offering recyclability, providing strength and durability, allowing for design versatility, resisting natural disasters, and reducing construction time. By incorporating steel billets into construction projects, we can create environmentally-friendly and long-lasting structures that promote sustainability in the built environment.

- Q: Our caster is square billet! 150X500! That is, every time we open the head, there is slag inclusion. And pores! Yes, the first 3 meters! There's no more left behind! How did it happen, please?! We have a refinery and electromagnetic stirring! Give me a hand!

- the only way to avoid pinhole of slag situation.1, after foaming, a large amount of gas and residue are produced, which is the main source of porosity and slag inclusion in the cast steel.2, steel casting pouring system or ingate structure is not reasonable, easy to make the gas and residue involved in the liquid metal, the formation of porosity and slag.3, pouring temperature is too low, can not make the cast steel parts of the gas and residue fully excluded, floating up to the top of the casting, but also easy to produce porosity and slag inclusion.4, in some parts of the cast steel parts, when the permeability of the paint is very low, due to the role of gas back pressure, it is easy to make the gasification gas wrapped in the epidermis, forming a package of gas".

- Q: What is the weight of a standard steel billet?

- The dimensions and specific alloy composition of a standard steel billet can cause its weight to fluctuate. On average, the weight of a standard steel billet falls between 1,000 and 1,500 kilograms, equivalent to 2,204 and 3,307 pounds. It is worth mentioning that steel billets may have varying standard sizes and weight ranges depending on the industry and region.

- Q: What are the different types of steel billet surface treatment defects?

- There are several types of steel billet surface treatment defects that can occur during the manufacturing process. These defects can affect the quality and appearance of the steel billets, and it is important to identify and address them to ensure the overall performance of the final product. 1. Scale: Scale is a common defect that occurs when the steel billet is exposed to high temperatures during the manufacturing process. It appears as a layer of oxide on the surface of the billet, which can affect the adhesion of coatings or paints. 2. Inclusions: Inclusions are non-metallic particles or impurities that can be present on the surface of the steel billet. These inclusions can be caused by various factors, such as inadequate cleaning or improper handling during the manufacturing process. They can negatively impact the mechanical properties of the steel and reduce its overall performance. 3. Decarburization: Decarburization is a defect that occurs when the surface layer of the steel billet loses its carbon content due to exposure to high temperatures or a lack of protective atmosphere. This can lead to reduced hardness and strength in the affected area. 4. Pitting: Pitting is a localized defect that appears as small cavities or pits on the surface of the steel billet. It can be caused by the presence of impurities or by exposure to corrosive environments. Pitting can compromise the structural integrity of the billet and make it more susceptible to corrosion. 5. Surface cracks: Cracks can occur on the surface of the steel billet due to various factors, such as thermal stress, improper handling, or inadequate cooling. Surface cracks can weaken the billet and increase the risk of failure during subsequent processing or use. 6. Surface roughness: Surface roughness refers to an uneven or irregular surface texture on the steel billet. It can be caused by factors such as improper machining, inadequate cleaning, or the presence of scale or inclusions. Surface roughness can affect the appearance of the billet and may also impact its performance in certain applications. Overall, it is crucial to identify and address these surface treatment defects to ensure the quality and reliability of steel billets. Proper manufacturing processes, including adequate cleaning, protective atmospheres, and appropriate handling, can help minimize the occurrence of these defects and ensure the optimal performance of the final product.

- Q: How are steel billets used in the production of crankshafts?

- Crankshafts rely on steel billets for their production, as these billets are essential in forming the foundation of this intricate component. Obtained through continuous casting or rolling of molten steel, steel billets are semi-finished products typically found in square or rectangular shapes. To create a crankshaft, the initial step involves heating the steel billet to a specific temperature, usually achieved through induction heating. This process enhances the billet's malleability, making it easier to shape. Once heated, the billet is placed into a forging machine, where it undergoes a series of compressive forces and plastic deformation. This gradual transformation results in the desired shape of the crankshaft. Throughout the forging process, the steel billet experiences immense pressure to ensure the metal grain structure aligns optimally. This alignment enhances the strength and durability of the crankshaft. Precise shaping of the crankshaft's main bearing journals, crankpin journals, and counterweights is achieved through carefully controlled forging techniques. Following the forging process, the partially finished crankshaft undergoes various machining operations, such as milling, turning, and grinding. These operations refine the crankshaft's dimensions and surface finish to meet the required specifications for smooth operation and efficient power transmission. In conclusion, steel billets are crucial raw materials in the production of crankshafts. Through the forging process, these billets are transformed into strong and resilient crankshafts capable of withstanding the demanding conditions of engines. The use of steel billets contributes to the production of crankshafts with superior strength, durability, and performance, making them vital components in the automotive and machinery industries.

- Q: What are the potential applications of steel billets in the transportation industry?

- In the transportation industry, steel billets offer a wide range of potential applications. One important use is their role in manufacturing various parts and components for automobiles, including engine blocks, chassis, suspension systems, and wheels. These critical components require the strength and durability that steel billets provide, ensuring the safety and reliability of vehicles. Furthermore, steel billets are commonly employed in the production of railway tracks, guaranteeing the stability and longevity of rail infrastructure. Their high strength and resistance to wear and tear make them an ideal choice, enabling them to withstand heavy loads and extreme weather conditions. Additionally, steel billets find application in ship and boat construction. The marine industry relies on their strength and corrosion resistance to build hulls, decks, and various structural components. Steel billets also play a crucial role in bridge construction, providing the necessary strength and structural integrity to support heavy traffic loads. Moreover, steel billets are extensively used in the manufacturing of aircraft parts and components. The aviation industry demands materials with an exceptional strength-to-weight ratio, and steel billets meet this requirement. They are utilized in the production of landing gear, engine mounts, and other critical aircraft structures. In summary, the potential applications of steel billets in the transportation industry are vast and diverse. Their strength, durability, and resistance to wear and tear make them indispensable for the production of parts and components in automobiles, railway tracks, ships, boats, aircraft, and bridges. Steel billets contribute to the safety, reliability, and efficiency of transportation systems, making them an essential material in this industry.

- Q: What is the role of steel billets in the construction of high-rise buildings?

- Steel billets play a vital role in the construction of tall buildings, serving as the raw material for structural components like beams, columns, and girders. Their exceptional strength and durability make them ideal for supporting heavy loads and resisting external forces such as wind and earthquakes. Furthermore, steel billets offer design and construction flexibility, allowing architects and engineers to create intricate and visually appealing structures. Their versatility also enables the construction of large spans, reducing the need for excessive supporting columns and maximizing usable space. In addition, steel billets are highly resistant to corrosion and fire, ensuring the longevity and safety of skyscrapers. The galvanized or coated surface protects against rust, while the fire-resistant properties of steel maintain its strength at high temperatures. Moreover, steel billets contribute to the sustainability and environmental efficiency of high-rise construction. The use of recycled steel billets reduces the demand for virgin resources and minimizes waste, aligning with sustainable development principles. In conclusion, steel billets are crucial for constructing tall buildings due to their strength, durability, flexibility, resistance to corrosion and fire, and contribution to sustainable development. They enable the creation of robust, safe, and aesthetically pleasing structures that can withstand various forces and optimize space utilization.

Send your message to us

Prime square alloy steel billet 85mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords