Prime Steel Billet Q275, 20MnSi, 5SP,Q235 for great sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STEEL BILLET

1.Brief description

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

2.Features

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

3.Processing

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

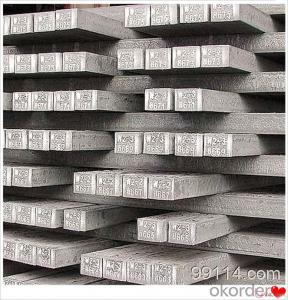

4.Pictures

5.Usage

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

6.Detailed specification

Hot rolled billet steel

Size: 50x50mm-180x180mm

Steel Grade: 3SP, 5SP,Q195,Q235,Q255,Q275 Length:3m-12m

MOQ: 1000MT/size

Payment term: TT or LC

Packing: in bulk , bundle

Shipment: by container , bulk vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: 15-30 days after the deposit

Loading port:Tianjin, or other port China

Origin : China

Inspection:Third party inspection before loading.

- Q: How are steel billets manipulated during the manufacturing process?

- Steel billets are manipulated in various ways during the manufacturing process to transform them into usable steel products. The manipulation techniques include heating, rolling, forging, and cutting. Firstly, the steel billets are heated in a furnace to a specific temperature, known as a rolling temperature. This heating process is crucial as it improves the billet's malleability and reduces its brittleness, making it easier to manipulate. Once heated, the billets are passed through a series of rolling mills. These mills apply pressure to the billets, which elongates and shapes them into the desired form. Rolling can be done using hot or cold methods, depending on the end product requirements. Hot rolling is typically used for large-scale production, while cold rolling is more commonly employed for precision applications. Another method of manipulating steel billets is forging. Forging involves applying compressive forces to the billets using hammers or presses. This process enhances the billet's strength, improves its grain structure, and refines its mechanical properties. Forged steel billets are often used in applications where high strength and resistance to impact and fatigue are required, such as in the automotive and aerospace industries. Cutting is also an essential manipulation technique during the manufacturing process. Steel billets are cut into desired lengths using saws or shears. This step ensures that the billets are converted into manageable sizes suitable for further processing or to meet specific customer requirements. In conclusion, steel billets undergo several manipulation techniques during the manufacturing process. These include heating, rolling, forging, and cutting. Each method contributes to transforming the raw billets into the desired shape and properties, ensuring they are suitable for various applications in industries such as construction, manufacturing, and transportation.

- Q: How are steel billets used in the manufacturing of medical devices?

- Steel billets are used in the manufacturing of medical devices in various ways. Firstly, steel billets serve as a raw material for the production of surgical instruments, such as scalpels, forceps, and scissors. These devices require a high level of strength, durability, and corrosion resistance, which steel billets can provide. Additionally, steel billets are used in the manufacturing of implants, such as joint replacements and dental implants. These devices need to be able to withstand the load and stress exerted by the human body, and steel billets are an ideal material due to their excellent mechanical properties. Moreover, steel billets are used in the production of medical equipment, such as hospital beds, wheelchairs, and surgical tables. These devices require a sturdy and robust structure, and steel billets can provide the necessary strength and stability. Furthermore, steel billets are also utilized in the manufacturing of medical equipment components, such as brackets, frames, and supports. These components play a crucial role in the functioning and stability of medical devices, and steel billets are often chosen due to their high machinability and weldability. Overall, steel billets are an essential raw material in the manufacturing of various medical devices. Their strength, durability, corrosion resistance, and other mechanical properties make them a suitable choice for producing surgical instruments, implants, medical equipment, and their components.

- Q: How are steel billets stored to prevent corrosion?

- Steel billets are typically stored in a way that prevents direct contact with moisture and oxygen, which are the primary causes of corrosion. One common method is to keep the billets indoors in a controlled environment, such as a warehouse or storage facility. These facilities are designed to maintain low humidity levels and are often equipped with climate control systems to regulate temperature and moisture content. To further protect against corrosion, steel billets can be stored on wooden pallets or racks, ensuring that they are kept off the ground and away from any potential sources of moisture. It is also common to apply a protective coating or oil film on the billets' surface before storage. This coating acts as a barrier, preventing moisture and oxygen from coming into direct contact with the steel and reducing the risk of corrosion. Regular inspections and maintenance are also essential to ensure that any signs of corrosion are promptly identified and addressed. This may involve periodic cleaning, applying additional protective coatings, or implementing other preventive measures as necessary. Overall, by storing steel billets in a controlled environment, applying protective coatings, and maintaining regular inspections, the risk of corrosion can be significantly reduced, ensuring that the billets remain in optimal condition for future use.

- Q: Can steel billets be polished for improved surface finish?

- No, steel billets cannot be polished for improved surface finish as they are usually unfinished or have a rough surface due to the manufacturing process.

- Q: How are steel billets used in the production of gear blanks?

- Steel billets are an essential component in the production of gear blanks. Gear blanks are the starting point for the manufacturing of gears. They are essentially the raw, unfinished pieces that will later be shaped and transformed into the final gear product. Steel billets, which are long, rectangular bars of steel, provide the necessary material for the creation of gear blanks. These billets are typically made from high-quality steel that possesses the required strength, durability, and machinability characteristics needed for gear production. To create gear blanks, the steel billets are first heated to a specific temperature to make them more malleable and easier to shape. The heated billets are then subjected to various forming processes, such as forging or extrusion, to transform them into the desired shape of the gear blank. Once the gear blank is formed, it undergoes further machining processes to refine its shape, dimensions, and surface finish. This may include operations such as turning, milling, drilling, or grinding. The precise machining ensures that the gear blank meets the required specifications for the final gear product. The gear blanks produced from steel billets serve as the foundation for the creation of various types of gears, such as spur gears, helical gears, bevel gears, or worm gears. These gear blanks undergo additional steps, such as heat treatment and surface hardening, to enhance their mechanical properties and increase their resistance to wear and fatigue. In summary, steel billets are integral to the production of gear blanks as they provide the raw material from which gears are formed. Through a series of heating, forming, and machining processes, the steel billets are transformed into gear blanks, which are then further processed to create the final gears used in various applications.

- Q: How is the quality of steel billets ensured during the manufacturing process?

- The quality of steel billets is ensured during the manufacturing process through various measures such as rigorous inspection and testing procedures. These include visual inspections, dimensional checks, and non-destructive testing techniques like ultrasonic testing or magnetic particle inspection. Additionally, chemical analysis is conducted to verify the composition of the steel billets, ensuring they meet the required specifications. By implementing these quality control measures, any potential defects or inconsistencies can be identified and addressed promptly, ensuring the production of high-quality steel billets.

- Q: What are the different types of steel billet welding processes?

- There are several different types of steel billet welding processes that are commonly used in various industries. These processes include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW involves a flux-coated electrode that is manually fed into the welding pool. It is a versatile and widely used process for welding steel billets. 2. Gas Metal Arc Welding (GMAW): This process, commonly known as MIG welding, uses a continuously fed wire electrode and a shielding gas to protect the weld pool. It is a popular method for welding steel billets due to its efficiency and ease of use. 3. Flux-Cored Arc Welding (FCAW): FCAW is similar to GMAW, but it uses a tubular electrode filled with flux instead of a solid wire. This process is often preferred for outdoor or windy conditions as the flux provides better protection against atmospheric contamination. 4. Submerged Arc Welding (SAW): SAW involves feeding a consumable electrode and a granular flux into the weld zone, while the arc remains submerged beneath a layer of flux. It is commonly used for welding large steel billets due to its high deposition rates and deep penetration capabilities. 5. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, GTAW uses a non-consumable tungsten electrode and a shielding gas to protect the weld pool. It is a precise and high-quality welding process suitable for thin steel billets or applications that require exceptional weld aesthetics. 6. Electroslag Welding (ESW): ESW is a highly efficient process used for welding thick steel billets. It involves melting a consumable electrode and the base metal in a molten slag pool, which provides protection and acts as a filler material. 7. Laser Beam Welding (LBW): LBW utilizes a high-energy laser beam to melt and join steel billets together. It is a precise and fast welding process commonly used in industries such as automotive and aerospace. Each of these welding processes has its own advantages and limitations, and the choice of process depends on factors such as the type and thickness of the steel billet, desired weld quality, production requirements, and cost considerations.

- Q: What are the common shipping methods for steel billets?

- Steel billets can be shipped using different methods, including container shipping, bulk shipping, and rail transportation. Container shipping is commonly used when transporting smaller quantities of billets. Billets are loaded into standard shipping containers, usually 20 or 40 feet long, and then transported by cargo vessels. This method is convenient and ensures the safety of the billets during transit. Bulk shipping, on the other hand, is preferred for larger quantities of steel billets. In this method, billets are loaded directly onto cargo vessels without using containers. This allows for cost-effective transportation of large volumes of billets. Specialized bulk carriers are designed to handle heavy cargo and ensure secure delivery. For domestic or regional transportation, rail transportation is a popular option. Steel billets are loaded onto specialized railcars that can carry heavy loads, and they are transported through rail networks. This method offers efficient and reliable transportation, especially for shorter distances. Ultimately, the choice of shipping method for steel billets depends on factors such as quantity, destination, cost, and logistical capabilities. Each method has its own advantages and considerations, so it is important to select the most suitable option based on the specific requirements of the shipment.

- Q: What are the different types of rolling processes used for shaping steel billets?

- There are several different types of rolling processes used for shaping steel billets. These processes are specifically designed to transform the raw material into desired shapes and sizes. One common rolling process used for shaping steel billets is hot rolling. In this process, the steel billet is heated to a high temperature and then passed through a series of rollers. The rollers apply pressure to the billet, causing it to elongate and change shape. Hot rolling is typically used for producing large-sized steel products such as bars, rods, and plates. Another type of rolling process is cold rolling. Unlike hot rolling, cold rolling does not involve heating the steel billet. Instead, it is performed at room temperature or slightly below. Cold rolling is known for its ability to produce finished products with high dimensional accuracy and a smooth surface finish. It is commonly used for manufacturing thin sheets, strips, and foils. A third type of rolling process used for shaping steel billets is ring rolling. Ring rolling involves rotating the billet between two rollers while applying pressure. This process is particularly useful for producing seamless rings with a hollow center, which are commonly used in applications such as bearings and gears. Additionally, there is a process called skew rolling, which is used to shape steel billets into round balls or cylindrical shapes. Skew rolling involves rotating the billet at an angle to the direction of the rollers while applying pressure. This process is widely used in the production of grinding media for mining and cement industries. Overall, these different types of rolling processes offer various advantages and are suited for specific applications. Whether it is hot rolling, cold rolling, ring rolling, or skew rolling, each process plays a crucial role in shaping steel billets into the desired forms required by various industries.

- Q: Can steel billets be used in the production of industrial equipment?

- Industrial equipment can indeed utilize steel billets. These semi-finished metal products can undergo further processing to produce a wide range of industrial equipment, including machinery, tools, automotive parts, construction materials, and more. Steel's exceptional strength, durability, and adaptability make it the perfect material for manufacturing industrial equipment. By shaping, machining, and welding steel billets, intricate structures and components can be created, ensuring the necessary strength and stability for industrial applications. Furthermore, heat treatment can be applied to steel billets to enhance their mechanical properties, making them even more suitable for heavy-duty industrial equipment.

Send your message to us

Prime Steel Billet Q275, 20MnSi, 5SP,Q235 for great sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords