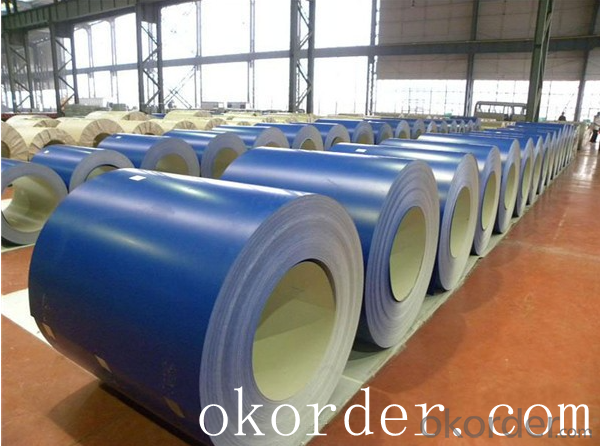

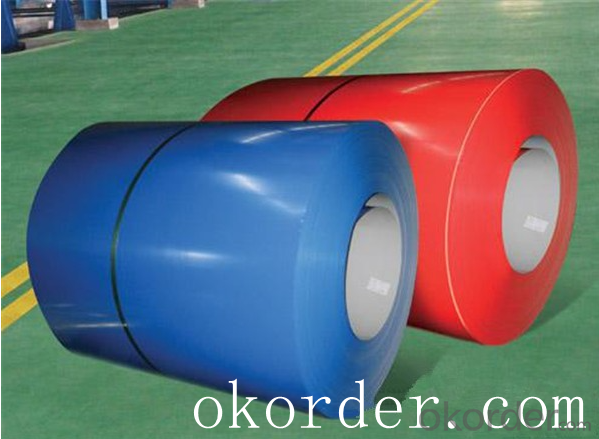

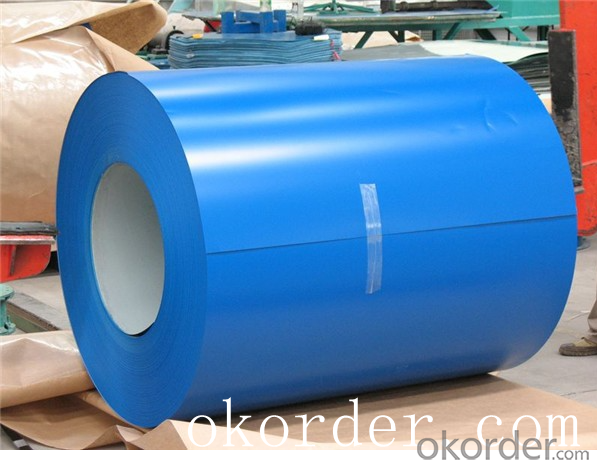

Prime quality prepainted galvanized steel 625mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

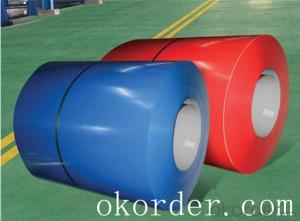

Construction building material galvanized color prepainted cold

rolled steel coil

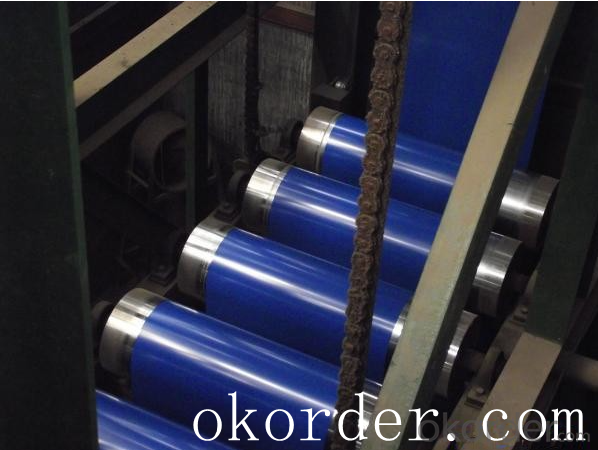

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q: Can steel billets be used for making cutlery?

- Yes, steel billets can be used for making cutlery. Steel billets are the raw material used in the production of various steel products, including cutlery. The billets are heated and then shaped into desired forms, such as knives, forks, or spoons, through processes like forging or casting. The resulting steel cutlery is known for its strength, durability, and ability to hold a sharp edge. However, it is important to note that the specific type of steel used and the manufacturing processes play a significant role in determining the quality and characteristics of the cutlery.

- Q: What is the role of steel billets in the construction of stadiums and arenas?

- Steel billets play a crucial role in the construction of stadiums and arenas as they are the primary raw material used to manufacture structural steel components. These billets are heated and shaped into various forms, such as beams, columns, and trusses, which provide the necessary support and framework for the overall structure. The high strength and durability of steel make it an ideal material to withstand the heavy loads and forces experienced in these large-scale facilities. Additionally, steel billets can be easily fabricated and assembled on-site, ensuring efficient construction and enabling the creation of complex designs and architectural features.

- Q: How are steel billets used in the manufacturing of forgings?

- Steel billets are used in the manufacturing of forgings as they serve as the initial raw material. These billets are heated and then shaped using a variety of forging techniques such as hammering or pressing, resulting in the desired forged product. The high strength and malleability of steel make it an ideal material for forgings used in various industries, including automotive, aerospace, and construction.

- Q: How is the strength of steel billets measured?

- The strength of steel billets is typically measured using a tensile test, where a sample is subjected to pulling forces until it fractures. The maximum force applied during the test is recorded and used to determine the strength of the steel.

- Q: How are steel billets used in the production of electrical appliances?

- Steel billets are used in the production of electrical appliances in several ways. Firstly, steel billets are often used as the raw material for manufacturing various components of electrical appliances. These billets can be shaped and molded into different forms such as sheets, plates, bars, or wires, depending on the specific needs of the appliance. For instance, steel billets can be rolled into thin sheets which are then used to form the outer casing or body of electrical appliances like refrigerators, washing machines, or air conditioners. These sheets provide durability, strength, and protection to the internal components of the appliance. Additionally, steel billets can be further processed to create bars or wires that are used in the production of electrical connections, circuit breakers, or switches. These components require high electrical conductivity, resistance to heat, and mechanical strength, which steel billets can provide. Furthermore, steel billets are also used to manufacture various motors and transformers that are integral to the functioning of electrical appliances. These billets are shaped and machined to create specific parts like rotor cores, stator cores, or laminated cores, which are essential for the efficient conversion of electrical energy. In summary, steel billets play a crucial role in the production of electrical appliances by providing the necessary raw material for creating components like casings, bars, wires, and cores. Their properties of strength, durability, electrical conductivity, and heat resistance make them an ideal choice for ensuring the reliability and functionality of electrical appliances.

- Q: Are billet metals within the metal range?

- Two kinds of billets, ferrous, ferrous and metallic, belong to ferrous metal, copper and copper alloy, aluminium and aluminium alloy, and belong to colored metal

- Q: What are the different types of surface defect detection methods for steel billets?

- There are several types of surface defect detection methods for steel billets, including visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and dye penetrant testing. Each method has its own advantages and limitations, and is used depending on the specific requirements and characteristics of the billets being inspected.

- Q: Are steel billets affected by extreme temperatures?

- Yes, steel billets can be affected by extreme temperatures. High temperatures can cause the billets to soften and become more malleable, making them easier to shape or deform. On the other hand, extremely low temperatures can make the steel brittle and prone to cracking or fracturing. Therefore, it is important to carefully control and monitor the temperature conditions during the production and processing of steel billets.

- Q: What are the different types of steel alloys used for manufacturing steel billets?

- Steel billets are manufactured using a variety of steel alloys, each designed to meet specific requirements for different applications. Carbon steel, for example, is a commonly used alloy that consists primarily of iron and carbon. Its strength and durability make it suitable for construction, automotive, and machinery purposes. Stainless steel, on the other hand, is composed of iron, chromium, and other elements like nickel and molybdenum. It is highly resistant to corrosion, making it ideal for applications in moist or harsh environments, such as marine equipment, medical instruments, and kitchen utensils. Alloy steel is another type of steel alloy used for manufacturing steel billets. By adding alloying elements like manganese, nickel, chromium, and vanadium to base iron, the strength, hardness, and wear resistance of the steel are enhanced. This type of steel is commonly used in aerospace components, automotive parts, and industrial machinery. Tool steel, a high-carbon alloy, contains additional elements such as tungsten, molybdenum, and vanadium. Its exceptional hardness, heat resistance, and wear resistance make it perfect for applications involving cutting, drilling, and shaping, such as cutting tools, drills, and molds. To summarize, carbon steel, stainless steel, alloy steel, and tool steel are all used in the manufacturing of steel billets. Each alloy offers specific properties and characteristics that make it suitable for various applications across different industries.

- Q: How are steel billets used in the production of turbine blades?

- Steel billets are used in the production of turbine blades as raw material. These billets are first forged into the desired shape and then undergo precision machining to achieve the required dimensions and finish. The steel billets provide the strength and durability necessary to withstand the high temperatures and forces experienced by turbine blades during operation.

Send your message to us

Prime quality prepainted galvanized steel 625mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords