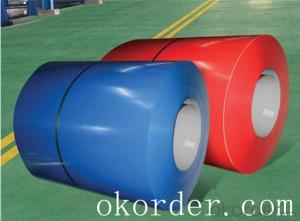

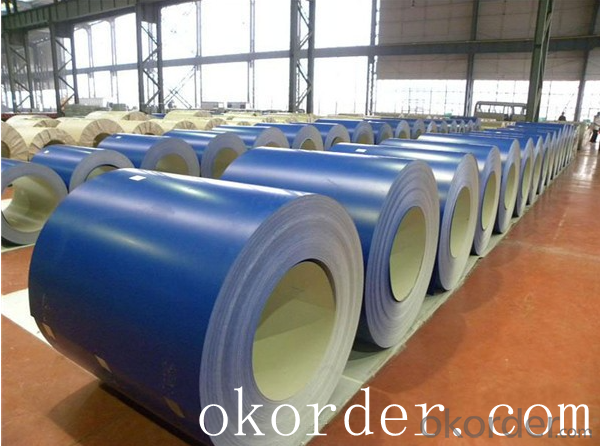

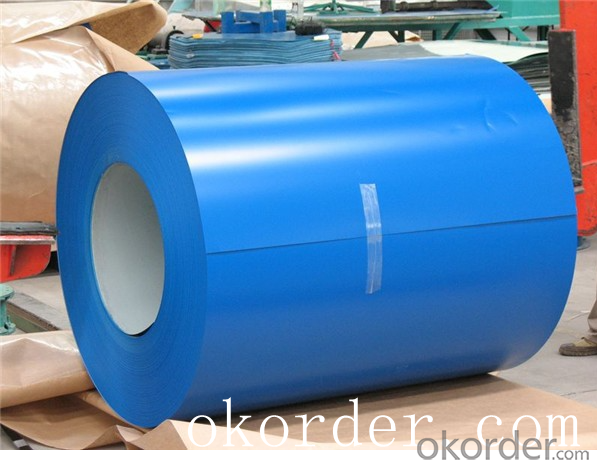

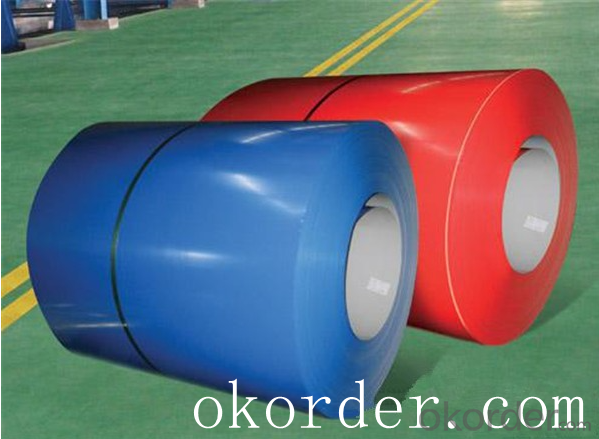

Prime quality prepainted galvanized steel 630mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q: Can steel billets be used in marine environments?

- Yes, steel billets can be used in marine environments. Steel is a popular choice for various marine applications due to its strength, durability, and corrosion resistance properties. Steel billets, which are semi-finished products, can be further processed into various marine components such as ship hulls, offshore platforms, and marine structures. To withstand the harsh conditions of marine environments including exposure to saltwater, steel used in these applications is typically treated with anti-corrosion coatings or alloys. These protective measures help prevent the corrosion of steel and maintain its structural integrity, ensuring it can withstand the corrosive effects of seawater and other marine elements. Moreover, steel billets can undergo additional processes such as hot rolling, forging, or extrusion to shape them into the desired marine components. These processes further enhance the mechanical properties of the steel, making it suitable for marine applications where high strength and resistance to impact and fatigue are required. Overall, steel billets can be effectively used in marine environments, provided they are properly treated and processed to withstand the corrosive nature of seawater and meet the specific requirements of marine applications.

- Q: What are the different surface treatments for improved surface lubrication in steel billets?

- There are several surface treatments that can be applied to steel billets to improve surface lubrication. These treatments aim to reduce friction and wear during various manufacturing processes, such as rolling or extrusion. Some of the common surface treatments for improved surface lubrication in steel billets include: 1. Phosphating: This treatment involves the application of a phosphate coating to the steel surface. Phosphating creates a thin layer of a phosphate compound, which acts as a lubricant and reduces friction between the billet and the machinery during processing. 2. Nitriding: Nitriding is a process that introduces nitrogen into the steel surface, forming a nitride layer. This layer improves the surface hardness and wear resistance of the billet, enhancing its lubrication properties and reducing friction. 3. Electroplating: Electroplating involves depositing a layer of metal, such as zinc or nickel, onto the steel billet's surface. This coating not only improves lubrication but also provides corrosion protection, extending the lifespan of the billet. 4. Surface coating: Various types of coatings, such as Teflon or other polymer-based coatings, can be applied to steel billets. These coatings create a low-friction surface, preventing sticking or galling during processing. 5. Shot peening: Shot peening is a mechanical surface treatment that involves bombarding the steel surface with small, high-velocity metal shots. This process induces compressive stress in the surface layer, increasing its resistance to wear and reducing friction. 6. Case hardening: Case hardening is a heat treatment process that involves the diffusion of carbon or other alloying elements into the steel surface. This treatment forms a hardened outer layer, which enhances lubrication properties and reduces friction during processing. Overall, these surface treatments for improved surface lubrication in steel billets offer various advantages, such as reduced wear, improved efficiency, and extended tool life. The choice of treatment depends on the specific application requirements and the desired properties of the billet.

- Q: How are steel billets rolled into shape?

- Steel billets are rolled into shape by passing them through a series of rolling mills, where they are subjected to high pressure and temperature. The billets are first heated to a specific temperature to make them more malleable. They are then continuously passed through multiple sets of rollers, which gradually decrease the thickness and increase the length of the billet. This process, known as hot rolling, helps shape the steel billets into various forms such as bars, rods, or sheets.

- Q: What types of steel are commonly used for billets?

- The types of steel commonly used for billets include carbon steel, alloy steel, and stainless steel.

- Q: What are the main challenges in the quality control of steel billets?

- Several factors can affect the quality and performance of steel billets, posing significant challenges in their quality control. Here, we outline some key obstacles in this regard: 1. Chemical Composition: The accurate chemical composition of steel billets is pivotal in determining their strength, durability, and mechanical properties. However, ensuring consistent chemical composition is challenging due to variations in raw materials, melting processes, and the presence of impurities. 2. Homogeneity: It is crucial to achieve uniformity in the microstructure and composition throughout the steel billet. Inadequate mixing or non-uniform cooling can lead to inconsistencies, resulting in weak areas and uneven mechanical properties. 3. Defect Detection: Detecting and eliminating defects in steel billets is essential to prevent failures during subsequent processing and usage. Common defects include cracks, inclusions, segregation, porosity, and surface irregularities. However, accurately and promptly detecting these defects can be challenging due to their size, complexity, and location. 4. Dimensional Accuracy: Consistency in the dimensions and shape of steel billets is vital for their further processing and use in various applications. Maintaining precise dimensions requires controlling variables such as casting speed, cooling rates, and mold design. 5. Surface Quality: The condition of the surface of steel billets is critical for subsequent operations like rolling, forging, or machining. Ensuring a smooth, clean, and defect-free surface is challenging due to factors such as scale formation, oxidation, decarburization, and surface contamination during handling and storage. 6. Heat Treatment: Proper heat treatment is often necessary to achieve the desired mechanical properties in steel billets. However, controlling the heating and cooling rates, as well as the soaking times, can be challenging due to variations in equipment, temperature monitoring, and quenching techniques. 7. Traceability: Maintaining traceability and documentation throughout the production process is crucial for quality control. Tracking the origin of raw materials, process parameters, testing records, and certifications can be challenging, especially in complex supply chains. To address these challenges in the quality control of steel billets, a combination of advanced testing techniques, robust process controls, skilled personnel, and continuous improvement initiatives is necessary.

- Q: How are steel billets used in the manufacturing of marine equipment?

- Steel billets are used in the manufacturing of marine equipment as they serve as raw materials that are subsequently forged or rolled into various components such as ship hulls, propeller shafts, and engine parts. These billets undergo a series of processes such as heating, rolling, and shaping to create the necessary strength and durability required for marine applications.

- Q: How are steel billets used in the manufacturing of consumer goods?

- Steel billets are a crucial raw material used in the manufacturing of consumer goods. These billets are primarily utilized as feedstock in various metalworking processes such as hot rolling, forging, and extrusion. By shaping and forming the steel billets into desired shapes, manufacturers are able to produce a wide range of consumer goods like automobiles, appliances, construction materials, and machinery components. The high strength and durability of steel make it an ideal choice for consumer goods, ensuring reliability and longevity in the final products.

- Q: How do steel billets contribute to the shipbuilding industry?

- Steel billets are a crucial component in the shipbuilding industry as they play a significant role in the construction of ships. These semi-finished products are essentially molten steel that has been solidified into a specific shape, usually a square or rectangular block. They are typically obtained through the process of continuous casting or ingot casting. One of the primary ways in which steel billets contribute to the shipbuilding industry is by providing the raw material for the fabrication of various ship components. These billets are further processed through rolling, forging, or extrusion to create different structural elements, such as plates, beams, angles, and channels. These components are then used in the construction of the hull, decks, bulkheads, and other structural parts of the ship. Steel billets also possess several advantageous properties that make them ideal for shipbuilding. Their high strength and durability ensure the structural integrity and longevity of the ship, enabling it to withstand the harsh marine environment and constant exposure to seawater. Moreover, steel billets have excellent weldability, which allows for efficient and reliable joining of various components during the ship assembly process. Furthermore, the use of steel billets in shipbuilding offers a cost-effective solution. Steel is readily available and abundant, making it a cost-efficient material choice for the construction of ships. Additionally, steel is highly recyclable, allowing for the reuse of steel billets and reducing environmental impact. In summary, steel billets are vital to the shipbuilding industry as they provide the raw material for the fabrication of various ship components. Their high strength, durability, weldability, and cost-effectiveness make them an ideal choice for constructing ships that can withstand the demanding marine environment. Ultimately, steel billets contribute to the safe and reliable operation of ships, supporting the growth and development of the shipbuilding industry.

- Q: How are steel billets used in the manufacturing of hydraulic systems?

- Steel billets are used in the manufacturing of hydraulic systems as they serve as the raw material for various components. Hydraulic systems require strong and durable parts to withstand the high pressures and forces involved. Steel billets, which are essentially semi-finished steel products, are first heated and then shaped into the desired form through processes like hot rolling or extrusion. These formed steel billets are then further processed to create different hydraulic system components such as cylinders, pistons, valves, and fittings. The use of steel billets provides several advantages in the manufacturing of hydraulic systems. Firstly, steel is known for its high strength and toughness, making it suitable for withstanding the extreme pressures and forces encountered in hydraulic systems. It also offers excellent resistance to corrosion, which is crucial considering the exposure to fluids and harsh environments in hydraulic systems. Furthermore, steel billets can be easily machined and welded, allowing for the creation of intricate and customized hydraulic components. The versatility of steel billets enables the production of various shapes and sizes required for different hydraulic system applications. Overall, steel billets play a vital role in the manufacturing of hydraulic systems by providing a strong, durable, and versatile material for the production of essential components. Their use ensures the reliability and efficiency of hydraulic systems, enabling them to perform their intended functions in various industries such as construction, manufacturing, and transportation.

- Q: How are steel billets used in the manufacturing of electrical equipment?

- Steel billets are often used as the raw material in the manufacturing of electrical equipment. They are typically melted and formed into specific shapes, such as coils or laminations, to create various components of electrical machinery. The high strength and durability of steel make it suitable for withstanding the demands of electrical equipment, ensuring reliable operation and long-term performance.

Send your message to us

Prime quality prepainted galvanized steel 630mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords