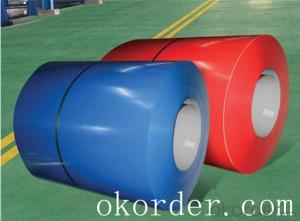

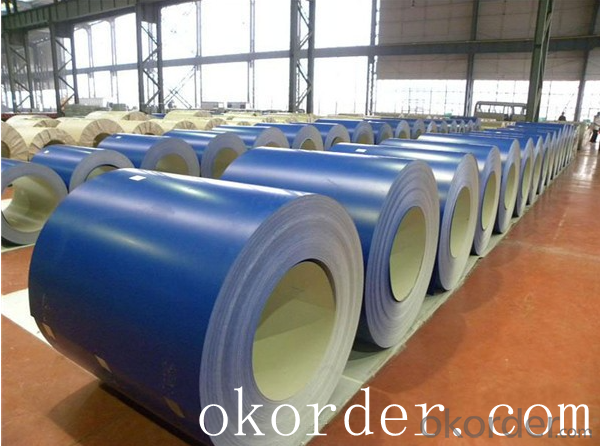

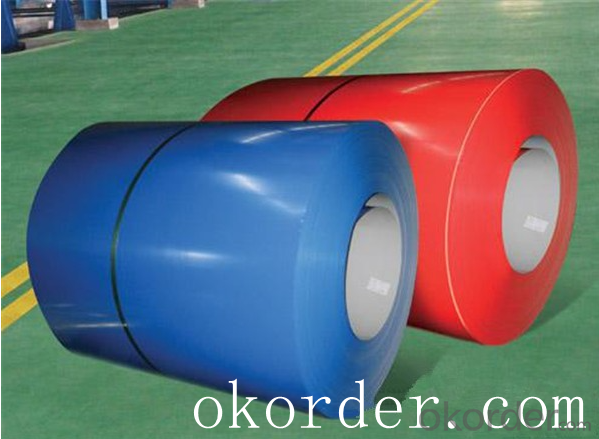

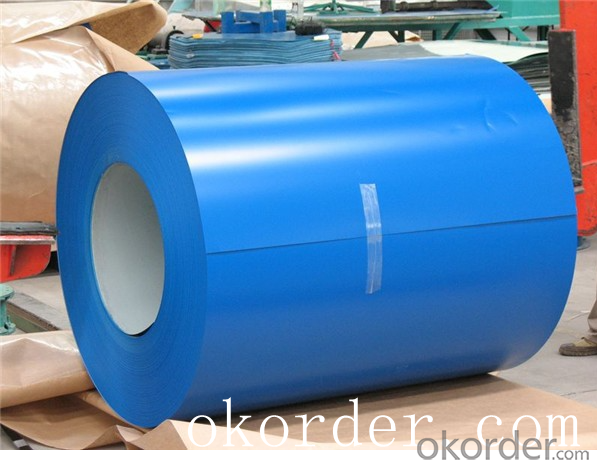

Prime quality prepainted galvanized steel 620mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q: What are the common defects in steel billets during hot rolling?

- During hot rolling, steel billets may experience certain defects that can affect the quality of the final product. Some common defects include: 1. Surface cracks: These are longitudinal cracks that occur on the surface of the billet. They can be caused by improper cooling, high rolling temperatures, or poor quality of the steel. Surface cracks can lead to weakened structural integrity and reduced product performance. 2. Internal cracks: These are cracks that occur within the billet, away from the surface. Internal cracks can be caused by inadequate billet heating, uneven temperature distribution, or improper rolling parameters. They can result in material failure or dimensional inconsistencies in the final product. 3. Surface defects: These can include scales, pits, or scars on the surface of the billet. They are often caused by poor billet preparation, inadequate scale removal, or improper rolling practices. Surface defects can affect the appearance and surface quality of the final product. 4. Lamination: Lamination defects occur when there are layers or planes of separation within the billet. They can be caused by impurities in the steel, improper billet preparation, or inadequate rolling parameters. Laminations can lead to reduced mechanical properties and structural integrity of the final product. 5. Warping: Warping defects occur when the billet undergoes uneven cooling or excessive rolling tensions. This can result in distortion or bending of the billet, leading to dimensional inconsistencies in the final product. 6. Inclusions: Inclusions are non-metallic particles or impurities that are trapped within the steel during the billet formation process. They can result in reduced mechanical properties, surface defects, or material failure in the final product. To minimize these defects, proper control of rolling parameters, billet preparation, and cooling processes is essential. Regular inspections and quality control measures should be implemented to identify and address any defects that may arise during hot rolling.

- Q: How are steel billets used in the manufacturing of defense equipment?

- Due to their strength, durability, and versatility, steel billets are crucial in the production of defense equipment. Armored vehicles, tanks, and artillery require materials that can withstand extreme conditions and offer optimal protection. Steel billets, which have a square or rectangular cross-section, are semi-finished steel products used as the raw material for various defense equipment components. These billets are melted and cast into specific shapes that meet the exact requirements of each equipment part. After casting, steel billets undergo forging, heat treatment, and machining processes to create different defense equipment components such as armor plates, gun barrels, missile casings, and vehicle frames. The high strength and impact resistance of steel billets make them ideal for these applications, ensuring the equipment can endure ballistic impacts, blast forces, and other hostile conditions encountered in combat situations. Additionally, steel billets can be easily welded, allowing for the assembly of complex structures and the integration of different components. This flexibility enables the production of customized defense equipment tailored to fulfill specific military needs. Furthermore, steel billets possess corrosion resistance, which is vital for defense equipment exposed to harsh environmental conditions like saltwater or extreme temperatures. This resistance ensures the longevity and reliability of the equipment, reducing maintenance requirements and costs. In summary, steel billets play a crucial role in the manufacturing of defense equipment as they provide the necessary strength, durability, and flexibility for effective performance in combat situations. Their usage guarantees that defense forces have access to reliable and robust equipment, enhancing their operational capabilities and safeguarding the lives of military personnel.

- Q: How are steel billets distributed in the market?

- Steel billets are distributed in the market through various channels and processes. These channels can be broadly categorized into three main methods: direct sales, through distribution networks, and online platforms. Direct sales involve manufacturers or steel mills selling their billets directly to customers, such as construction companies, fabricators, or steel service centers. This method allows manufacturers to have better control over pricing, quality, and delivery schedule. It also enables them to build direct relationships with customers and understand their specific requirements. Distribution networks play a significant role in the distribution of steel billets. These networks consist of wholesalers, distributors, and stockists who purchase steel billets from manufacturers and sell them to end-users or smaller retailers. Distribution networks have extensive market reach, allowing them to cater to a wide geographical area. They provide convenience to customers by maintaining an inventory of steel billets, ensuring timely availability and reducing lead times. In recent years, online platforms have emerged as a popular method for distributing steel billets. Online trading platforms connect buyers and sellers of steel billets, providing a convenient and efficient way to conduct business transactions. These platforms allow manufacturers to reach a global customer base, while buyers can access a wide range of suppliers and compare prices and specifications. Online platforms also provide transparency and reduce the need for intermediaries, resulting in cost savings. Regardless of the distribution method, the logistics of steel billets' transportation and storage are crucial. Steel billets are typically transported in bulk using various modes of transportation, including trucks, trains, or ships. To ensure the quality and integrity of the billets, proper storage facilities are necessary, which include warehouses or yards equipped with cranes and heavy-duty machinery. Overall, the distribution of steel billets involves a complex network of manufacturers, distributors, and online platforms, all working together to meet the diverse needs of customers. This ensures a steady supply of steel billets in the market, supporting various industries such as construction, manufacturing, and infrastructure development.

- Q: What is the average cost of steel billets?

- Several factors can influence the average cost of steel billets, including the type of steel, market conditions, and global supply and demand. Steel billets are semi-finished metal products commonly used as raw materials for various steel products. As of September 2021, the average price of steel billets ranges from $400 to $600 per metric ton. However, it is important to be aware that this price can fluctuate significantly due to factors such as changes in raw material costs (such as iron ore and scrap metal), energy prices, transportation costs, and market dynamics. Furthermore, specific countries or regions may experience variations in the average cost of steel billets due to regional factors like import tariffs, trade restrictions, and currency exchange rates. It is always recommended to seek advice from industry experts, steel suppliers, or consult market reports for the most accurate and up-to-date information on the current average cost of steel billets.

- Q: What are the main challenges in steel billet production?

- Manufacturers and producers face several key challenges in the production of steel billets. One of the primary hurdles is the need to guarantee a consistent and uniform quality for the billets. These semi-finished products are further processed into various steel items, and any irregularities or variations in their quality can lead to defects or failures in the final products. Consequently, it is crucial to maintain strict quality control measures throughout the production process. Another significant challenge revolves around optimizing the production process to meet desired quantity and quality targets while minimizing costs. This entails efficiently utilizing resources such as raw materials, energy, and labor. Additionally, striking a balance between production speed and quality can be challenging, as increasing the speed may result in reduced quality or increased defects. Ensuring the safety of workers and the environment also poses a major challenge in steel billet production. The production process involves heavy machinery, high temperatures, and potentially hazardous materials, which can jeopardize the health and safety of workers. To address this, it is imperative to implement proper safety protocols, provide training, and ensure compliance with regulatory standards. Furthermore, meeting the constantly growing demand for steel billets presents a challenge for producers. Market demand fluctuates, necessitating the ability to adjust production capacity accordingly. This requires flexibility in production planning and efficient inventory management to avoid overproduction or stock shortages. Lastly, technological advancements and innovations within the steel industry bring both challenges and opportunities. Incorporating new technologies, such as automation, artificial intelligence, and data analytics, can enhance efficiency and productivity. However, integrating these technologies into existing production processes can be complex and often requires substantial investments and expertise. In summary, the primary challenges in steel billet production include maintaining consistent quality, optimizing production processes, ensuring safety, meeting market demand, and adapting to technological advancements. Overcoming these challenges necessitates continuous improvement, innovation, and a proactive approach to remain competitive in the steel industry.

- Q: How are steel billets used in the manufacturing of chemical processing equipment?

- Steel billets are used in the manufacturing of chemical processing equipment as raw material for forging or casting various components such as valves, pumps, heat exchangers, and reactors. These billets are shaped, machined, and treated to meet the specific requirements of the equipment, ensuring strength, durability, and resistance to corrosion and high temperatures.

- Q: What are the different surface finishing techniques used for steel billets?

- Some of the different surface finishing techniques used for steel billets include shot blasting, pickling, and grinding. Shot blasting involves propelling abrasive particles at high speeds to remove rust, scale, and other surface contaminants. Pickling is a chemical process that uses acids to remove oxides, scale, and other impurities from the surface of the steel billets. Grinding is a mechanical process that uses abrasive wheels to smooth and polish the surface of the billets, creating a desired finish. These techniques help improve the surface quality and prepare the steel billets for further processing or use.

- Q: Does anyone know how much it costs to refine a ton of steel? What are the expenses involved?

- Electricity, water, wages, raw materials, raw materials loss, charges, oxygen, according to their own circumstances, as well as freight and other expenses, now the steel profits are not as good as before, a ton of net profit is about 100 yuan

- Q: What industries use steel billets?

- Several industries use steel billets, including automotive, construction, manufacturing, and infrastructure. Steel billets are commonly used as raw material in the production of various metal products such as pipes, rods, bars, wires, and sheets. They are also utilized in the construction of bridges, buildings, and other structural components. The automotive industry uses steel billets for manufacturing parts like engine blocks, chassis, and suspension components. Additionally, steel billets find applications in the energy sector, machinery production, and shipbuilding.

- Q: What is the role of steel billets in the manufacturing of offshore structures?

- The manufacturing of offshore structures heavily relies on steel billets, as they play a vital role in its construction. These structures face challenging environmental conditions, including corrosive saltwater, high winds, and extreme temperatures. Hence, it is crucial to opt for materials that possess strength, durability, and resistance against corrosion. Steel billets serve as the primary material required for the creation of these offshore structures. They are produced through a process called casting and are semi-finished steel products. Typically, billets come in rectangular or square shapes and possess larger cross-sectional areas compared to the final product. This allows for further processing and shaping into various components of the offshore structure. Once the steel billets are obtained, they undergo a series of manufacturing processes, including heating, rolling, and shaping, to transform them into the desired structural elements. These elements comprise beams, columns, plates, and other components that constitute the framework of the offshore structure. The utilization of steel billets offers numerous advantages in the fabrication of offshore structures. Firstly, steel is renowned for its exceptional strength and durability, enabling it to withstand the enormous forces exerted by ocean waves and ensure the structural stability of the offshore platform or rig. Moreover, steel possesses excellent fatigue resistance, allowing it to endure constant loading and unloading cycles without weakening. Furthermore, steel billets can be easily welded, which is a critical aspect of offshore structure construction. Welding enables the joining of various components, ensuring the overall integrity and strength of the structure. This facilitates the creation of large and intricate structures capable of withstanding the challenging marine environment. Additionally, steel billets possess outstanding corrosion resistance properties. Since offshore structures are constantly exposed to saltwater, which can lead to corrosion and material degradation, steel can be treated with protective coatings or alloys to enhance its resistance to corrosion. This ensures the longevity and safety of the offshore structure. In conclusion, steel billets serve as a fundamental component in the manufacturing process of offshore structures. They provide the necessary raw material for the creation of robust, long-lasting, and corrosion-resistant components, which form the framework of these structures. By utilizing steel billets, offshore structures can be constructed to withstand the demanding conditions of the marine environment, ensuring the safety of workers and the durability of the structure.

Send your message to us

Prime quality prepainted galvanized steel 620mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords