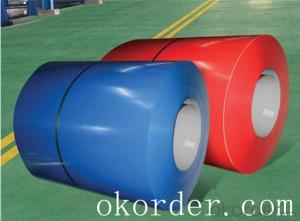

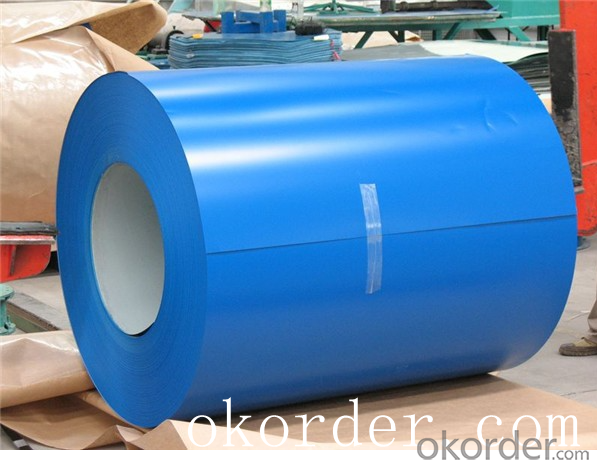

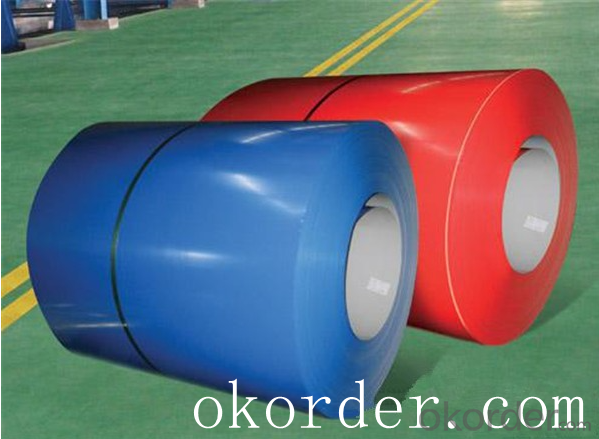

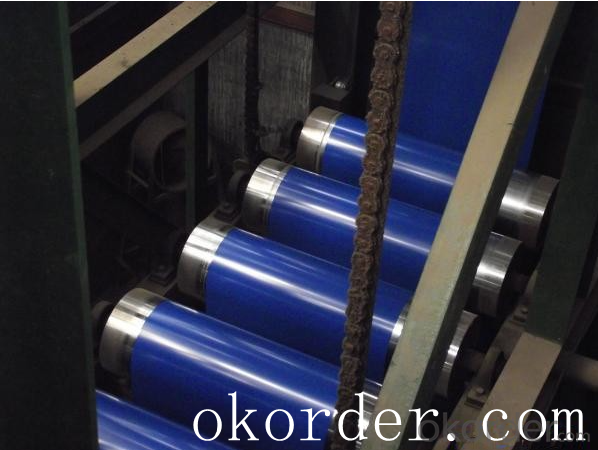

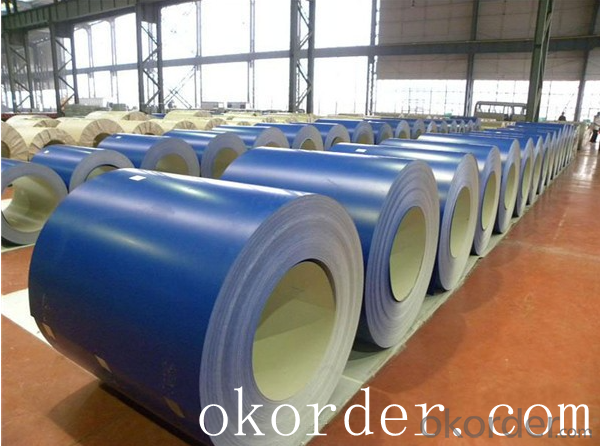

Prime quality prepainted galvanized steel 610mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

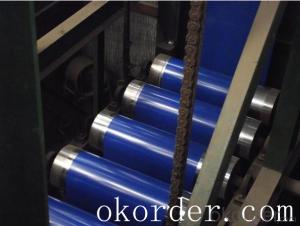

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q: What are the main types of defects found in steel billets?

- The main types of defects found in steel billets include surface defects such as cracks, pits, and scars, internal defects like inclusions, blowholes, and voids, as well as dimensional defects such as improper shape, size, or straightness.

- Q: What is the role of steel billets in the manufacturing of railway signaling systems?

- Steel billets play a crucial role in the manufacturing of railway signaling systems as they are used as the primary raw material for producing various components, such as brackets, supports, and housings. These components provide structural integrity and stability to the signaling systems, ensuring their proper installation and functioning along railway tracks. The strength and durability of steel billets make them an ideal choice for withstanding the demanding conditions of railway environments, including heavy loads, vibrations, and extreme temperatures. Ultimately, steel billets serve as the foundation for the reliable and efficient operation of railway signaling systems, enhancing safety and facilitating smooth train movements.

- Q: What are the different international standards for steel billets?

- There are several international standards for steel billets, including the American Society for Testing and Materials (ASTM) standards, the International Organization for Standardization (ISO) standards, and the European Committee for Standardization (EN) standards. These standards define the chemical composition, mechanical properties, and dimensions of steel billets, ensuring their quality and compatibility for various industries and applications worldwide.

- Q: Are steel billets used in the production of furniture?

- No, steel billets are typically not used in the production of furniture. Steel billets are semi-finished products made from molten iron that are later shaped into various forms, such as bars, rods, or sheets, through a process called hot rolling. While steel may be used in the manufacturing of furniture, it is usually in the form of finished products such as steel tubing, steel sheets, or steel frames. These finished steel products are more commonly used in the construction of furniture, particularly in industrial or modern designs. The use of steel in furniture production provides durability, strength, and a sleek aesthetic. However, the steel used in furniture manufacturing is usually obtained through different processes than the production of steel billets.

- Q: What is the typical size and shape of steel billets?

- Steel billets commonly have a rectangular or square form and are available in different dimensions. The prevailing measurements usually vary from 100mm x 100mm to 300mm x 300mm, while the lengths typically span from 3 meters to 12 meters. Nevertheless, the size and configuration of steel billets are subject to change based on the particular demands of the steel manufacturing process and the intended purpose of the billets.

- Q: How are steel billets used in the production of wire rods and bars?

- Steel billets are used in the production of wire rods and bars as they serve as the initial raw material. These billets are heated and then rolled or forged into long, slender shapes to create wire rods or bars. The size and shape of the billets determine the final dimensions of the wire rods or bars, which are used in various industries such as construction, automotive, and manufacturing.

- Q: Charcoal is how to

- Now, there is a method of using sawdust and other waste materials to process the charcoal, which is formed by pressing the waste materials into the furnace and heating them indirectly. The raw materials are carbonized into charcoal.The quality of charcoal can only be raised according to different uses.

- Q: What are the different methods of surface inspection for steel billets?

- Steel billets can undergo various methods of surface inspection to identify defects or irregularities. These include visual inspection, magnetic particle inspection, liquid penetrant inspection, ultrasonic inspection, and eddy current inspection. The simplest and most commonly used method is visual inspection, where inspectors visually examine the billet surface for visible defects such as cracks, pits, or irregularities. This method relies on the expertise and experience of the inspector. Magnetic particle inspection involves the use of magnetic fields and particles to detect surface and near-surface defects. By applying a magnetic field and particles to the billet surface, any defects attract particles, making them visible under proper lighting. Liquid penetrant inspection is another method used to detect surface defects. It involves applying a penetrant to the surface, which seeps into defects. After removing excess penetrant, a developer is applied to draw out the penetrant from the defects, making them visible. Ultrasonic inspection uses high-frequency sound waves to detect internal and surface defects. Sound waves are emitted into the billet using a transducer, and the reflected waves are analyzed to identify defects such as cracks, voids, and inclusions. Eddy current inspection is a non-destructive testing method that uses electromagnetic induction to detect surface defects. By moving a probe over the billet surface and passing an alternating current through it, any irregularities or defects disrupt the current flow, which can be detected and analyzed. Each method has its own advantages and limitations, and the choice depends on specific inspection requirements and constraints. Manufacturers utilize these methods to ensure the quality and reliability of steel billets before further processing or use in various applications.

- Q: How do steel billets contribute to the sustainability of construction projects?

- There are several ways in which steel billets contribute to the sustainability of construction projects. Firstly, steel is an extremely durable material that lasts a long time. Steel billets, which are the raw form of steel, can be used to manufacture various construction components such as beams, columns, and reinforcement bars. These components provide buildings with structural integrity and strength, ensuring their longevity. By using steel billets, construction projects can withstand extreme weather conditions and natural disasters, thus reducing the need for frequent repairs or replacements. This durability directly contributes to the sustainability of construction projects by reducing waste and conserving resources over time. Secondly, steel is highly recyclable. Steel billets can be recycled and reused indefinitely without losing their quality or performance. Recycling steel reduces energy consumption, greenhouse gas emissions, and waste associated with the production of new steel. By incorporating recycled steel billets into construction projects, the demand for new steel can be reduced, thus conserving natural resources and minimizing environmental impact. Furthermore, the use of steel billets in construction allows for efficient and versatile designs. Steel has a high strength-to-weight ratio, which means that lighter and slimmer structural elements can be used, requiring fewer materials. This not only reduces the overall weight of the building but also decreases the amount of concrete and other construction materials needed. As a result, less energy is consumed in the production and transportation of these materials, leading to a more sustainable construction process. Moreover, steel is resistant to pests such as termites and fungi, which can cause significant damage to buildings. By using steel billets, construction projects can avoid the need for chemical treatments typically required to protect wooden structures. This reduces the environmental impact of pest control measures. In conclusion, steel billets contribute to the sustainability of construction projects through their durability, recyclability, efficient design possibilities, and resistance to pests. By incorporating steel into construction, buildings can be built to last, reduce waste, conserve resources, and minimize environmental impact.

Send your message to us

Prime quality prepainted galvanized steel 610mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords