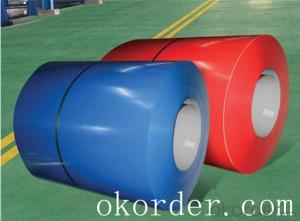

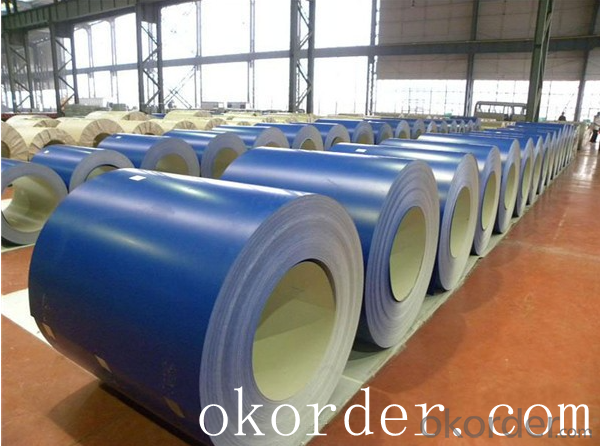

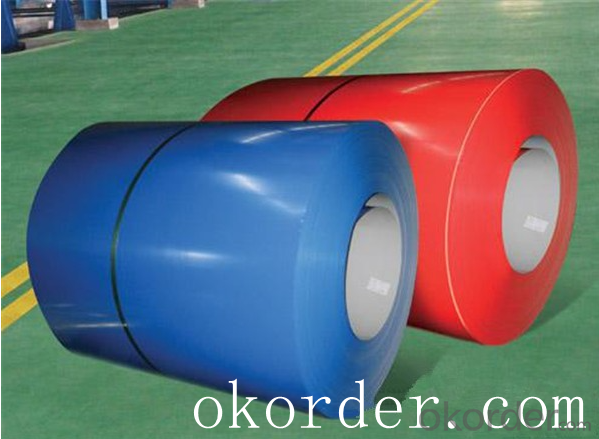

Prime quality prepainted galvanized steel 635mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q: What are the different surface treatments for improved surface lubrication in steel billets?

- To enhance surface lubrication, there are multiple techniques available for treating steel billets. These treatments target the reduction of friction and wear during manufacturing processes like rolling or extrusion. Some commonly used methods to improve surface lubrication in steel billets are: 1. Phosphating: By applying a phosphate coating to the steel surface, this treatment creates a thin layer of phosphate compound. Acting as a lubricant, it minimizes friction between the billet and machinery during processing. 2. Nitriding: Through the introduction of nitrogen into the steel surface, nitriding forms a nitride layer. This layer enhances the billet's surface hardness, wear resistance, and lubrication properties, reducing friction. 3. Electroplating: This treatment involves depositing a layer of metal, such as zinc or nickel, onto the surface of the steel billet. Besides improving lubrication, it also offers corrosion protection, extending the billet's lifespan. 4. Surface coating: Different types of coatings, such as Teflon or polymer-based coatings, can be applied to steel billets. These coatings create a low-friction surface, preventing sticking or galling during processing. 5. Shot peening: Shot peening is a mechanical surface treatment that bombards the steel surface with small, high-velocity metal shots. This process induces compressive stress in the surface layer, enhancing wear resistance and reducing friction. 6. Case hardening: Case hardening involves the diffusion of carbon or other alloying elements into the steel surface through heat treatment. This treatment forms a hardened outer layer, improving lubrication properties and reducing friction during processing. In summary, these surface treatments offer advantages such as reduced wear, improved efficiency, and extended tool life for steel billets. The choice of treatment depends on specific application requirements and the desired properties of the billet.

- Q: What are the different types of welding processes used for joining steel billets?

- There are several different types of welding processes that can be used for joining steel billets. Each method has its own unique characteristics and advantages, depending on the specific requirements of the project. Here are some of the most commonly used welding processes for joining steel billets: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW uses a consumable electrode coated in flux to create an arc between the electrode and the base material. This process is versatile and can be used for both thick and thin steel billets, making it widely used in various industries. 2. Gas Metal Arc Welding (GMAW): Commonly known as MIG welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld from atmospheric contamination. This process offers high productivity and is suitable for welding steel billets of various thicknesses. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuously fed tubular electrode filled with flux. This process is ideal for welding thicker steel billets and is often used in heavy fabrication applications. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, GTAW uses a non-consumable tungsten electrode and a separate filler metal. This process produces high-quality welds and is commonly used for joining steel billets in applications that require precision and aesthetic appeal. 5. Submerged Arc Welding (SAW): SAW involves the use of a continuously fed electrode and a granular flux that covers the weld area. The process is particularly suitable for welding thick steel billets and is often used in the construction of pressure vessels and heavy machinery. 6. Laser Beam Welding (LBW): LBW utilizes a laser beam to generate heat and join the steel billets. This process offers high precision and speed, making it suitable for a wide range of applications, including automotive and aerospace industries. 7. Electron Beam Welding (EBW): EBW uses a high-velocity electron beam to melt and join the steel billets. This process provides deep penetration and precise control, making it ideal for critical applications that require high-quality welds. It is important to consider the specific requirements, thickness, and material properties of the steel billets when selecting the appropriate welding process. Consulting with a welding expert can help determine the most suitable method for a given project.

- Q: What are the main factors affecting the quality of steel billets?

- Steel billets' quality can be significantly influenced by various key factors. These factors consist of the steel's composition, the heating process's temperature and duration, the cooling rate, and the existence of impurities. To begin with, the steel's composition plays a vital role in determining its quality. Elements like carbon, manganese, and silicon can impact the steel's mechanical properties, including its strength and hardness. Therefore, it is crucial to control and balance these alloying elements appropriately to ensure the desired quality of the steel billets. Secondly, the temperature and duration of the heating process during steel billet production are critical factors. Precise control of the heating process is necessary to attain the optimal temperature for the desired transformation of the microstructure. Improper heating, whether overheating or underheating, can result in the formation of unwanted phases or an inconsistent microstructure, negatively affecting the billets' quality. The cooling rate is another important factor that affects the quality of steel billets. It is essential to regulate the cooling process to achieve the desired microstructure and mechanical properties. Excessively rapid cooling can lead to the formation of brittle phases or residual stresses, while slow cooling can produce coarse-grained structures with reduced strength. Furthermore, the presence of impurities in the steel can significantly impact its quality. Impurities like sulfur, phosphorus, and non-metallic inclusions can decrease the steel billets' mechanical properties and promote defect formation. Thus, strict control over raw materials and effective refining techniques are necessary to minimize the occurrence of impurities. In conclusion, the quality of steel billets is influenced by factors such as the steel's composition, the temperature and duration of the heating process, the cooling rate, and the presence of impurities. By carefully controlling and optimizing these factors, steel manufacturers can produce high-quality billets that meet the desired specifications and performance requirements.

- Q: What are the different types of steel alloys used for manufacturing steel billets?

- Steel billets are manufactured using a variety of steel alloys, each designed to meet specific requirements for different applications. Carbon steel, for example, is a commonly used alloy that consists primarily of iron and carbon. Its strength and durability make it suitable for construction, automotive, and machinery purposes. Stainless steel, on the other hand, is composed of iron, chromium, and other elements like nickel and molybdenum. It is highly resistant to corrosion, making it ideal for applications in moist or harsh environments, such as marine equipment, medical instruments, and kitchen utensils. Alloy steel is another type of steel alloy used for manufacturing steel billets. By adding alloying elements like manganese, nickel, chromium, and vanadium to base iron, the strength, hardness, and wear resistance of the steel are enhanced. This type of steel is commonly used in aerospace components, automotive parts, and industrial machinery. Tool steel, a high-carbon alloy, contains additional elements such as tungsten, molybdenum, and vanadium. Its exceptional hardness, heat resistance, and wear resistance make it perfect for applications involving cutting, drilling, and shaping, such as cutting tools, drills, and molds. To summarize, carbon steel, stainless steel, alloy steel, and tool steel are all used in the manufacturing of steel billets. Each alloy offers specific properties and characteristics that make it suitable for various applications across different industries.

- Q: How do steel billets contribute to the oil and gas industry?

- Steel billets are essential components in the oil and gas industry, playing a significant role in various applications. These billets are semi-finished metal products that are used as raw materials for manufacturing pipes, valves, fittings, and other equipment required in the extraction, transportation, and refining of oil and gas. One of the primary uses of steel billets in the industry is for the production of seamless pipes. These pipes are crucial for the transportation of oil and gas over long distances, as they provide a secure and reliable means of conveying these valuable resources. Steel billets are heated and then rolled into seamless pipes, which offer excellent strength, durability, and resistance to high-pressure environments. These pipes are utilized in offshore drilling, subsea pipelines, and other critical applications within the oil and gas sector. Moreover, steel billets are also utilized in the manufacturing of various valves and fittings used in oil and gas infrastructure. Valves are crucial for controlling the flow of oil and gas throughout the production and transportation processes. Steel billets are shaped into valve bodies, which are then machined to precise specifications, ensuring proper functionality and reliability. Similarly, fittings, such as couplings, elbows, and tees, are manufactured from steel billets to connect different sections of pipelines and equipment, providing a secure and leak-free system. Furthermore, steel billets contribute to the oil and gas industry by being a primary material for constructing storage tanks and pressure vessels. These tanks are used for the storage of crude oil, natural gas, and various petroleum products. Steel billets are transformed into plates, which are then welded together to form these large-scale storage containers. The inherent strength and corrosion resistance of steel make it an ideal material for such applications, ensuring the safe containment of valuable resources. In summary, steel billets are essential to the oil and gas industry as they are transformed into various components used in the extraction, transportation, and refining processes. From seamless pipes for long-distance transportation to valves, fittings, and storage tanks, steel billets provide the necessary strength, durability, and reliability required in this demanding industry.

- Q: What is the global production capacity of steel billets?

- Accurately estimating the global production capacity of steel billets proves challenging due to its annual fluctuations and susceptibility to factors like market demand, economic conditions, and technological advancements. Nonetheless, the World Steel Association reports that in 2019, the total global production capacity for steel billets stood at around 1.86 billion metric tons. This capacity is distributed among different countries and steel-producing regions, with China leading as the largest producer, trailed by India, Japan, and the United States. It is crucial to acknowledge that these statistics are subject to alteration as the steel industry evolves and grows.

- Q: How do steel billets contribute to the overall seismic resistance of a structure?

- The overall seismic resistance of a structure is greatly improved by the presence of steel billets. When incorporated into concrete structures, steel billets act as reinforcement, boosting the structure's strength and longevity. This reinforcement enables the structure to better endure the forces and vibrations unleashed by earthquakes. The impressive tensile strength of steel billets enables them to efficiently absorb and distribute seismic energy, significantly decreasing the likelihood of structural failure during an earthquake. Moreover, steel billets have the capacity to be transformed into specialized structural elements, such as braces or shear walls, which are strategically positioned within the structure to counteract the lateral forces resulting from earthquakes. By utilizing steel billets, these structural elements are able to effectively absorb and disperse the seismic energy, successfully safeguarding the overall structure from substantial harm. Furthermore, steel billets are instrumental in the construction of seismic dampers, which are devices created to soak up and dissipate the energy generated by seismic events. When steel billet-based dampers are installed, the structure is able to significantly diminish the transfer of seismic energy to the building, thereby minimizing the potential for damage. Additionally, steel billets possess outstanding ductility, which is the capacity to deform without breaking. During an earthquake, structures experience considerable movement and vibrations. The ductile nature of steel allows it to flex and bend under these forces, proficiently absorbing seismic energy and preventing sudden, catastrophic failure of the structure. In conclusion, steel billets enhance the overall seismic resistance of a structure by providing additional strength and durability, facilitating the creation of specialized structural elements, enabling the construction of seismic dampers, and offering exceptional ductility. Their application elevates the structure's ability to withstand seismic forces, reducing the risk of damage and ensuring the safety of its occupants.

- Q: What are the potential applications of steel billets in the food and beverage sector?

- Steel billets have a variety of potential applications in the food and beverage sector due to their strength, durability, and hygienic properties. These billets can be used to manufacture equipment such as food processing machinery, storage tanks, and transportation containers, ensuring safe and efficient handling of food and beverages. Additionally, steel billets can be utilized in the construction of commercial kitchen infrastructure, providing a strong and reliable foundation for food preparation areas.

- Q: What are the different grades of steel billets?

- There are several different grades of steel billets, including low carbon steel, medium carbon steel, high carbon steel, alloy steel, and stainless steel. The specific grade of steel billet used depends on the intended application and desired properties of the final product.

- Q: What are the different surface treatments for steel billets?

- There are several different surface treatments that can be applied to steel billets to enhance their performance and protect them from corrosion. One common surface treatment is hot-dip galvanizing, where the steel billets are dipped into a bath of molten zinc. This creates a protective coating of zinc on the surface of the billets, which acts as a barrier against moisture and other corrosive elements. Another option is electroplating, where a thin layer of metal, such as chromium or nickel, is deposited onto the surface of the steel billets using an electric current. This not only provides corrosion resistance but can also improve the appearance of the billets. A third surface treatment method is painting or powder coating. This involves applying a layer of paint or dry powder onto the surface of the billets. The paint or powder forms a protective barrier that prevents moisture and other corrosive substances from reaching the steel. Additionally, shot blasting or sandblasting can be used as a surface treatment for steel billets. This involves propelling abrasive particles at high speeds onto the surface of the billets to remove any impurities or scale, leaving a clean and smooth finish. Lastly, there are also chemical treatments available for steel billets. One example is phosphating, where the steel is immersed in a phosphoric acid solution, resulting in the formation of a protective phosphate coating on the surface. This coating improves corrosion resistance and promotes paint adhesion. Overall, the choice of surface treatment for steel billets depends on the specific requirements of the application and the desired level of protection against corrosion and other environmental factors.

Send your message to us

Prime quality prepainted galvanized steel 635mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords