Prime Newly 3SP CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description of Prime Newly 3SP CNBM Steel Billets with High Quality

| GRADE | SIZE | APPLICATION |

| 3SP | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Prime Newly 3SP CNBM Steel Billets with High Quality

| 3SP | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.14-0.22 | 0.15-0.30 | 0.40-0.65 | 0.040% Max | 0.05Max |

Company Information for Prime Newly 3SP CNBM Steel Billets with High Quality:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery of Prime Newly 3SP CNBM Steel Billets with High Quality

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

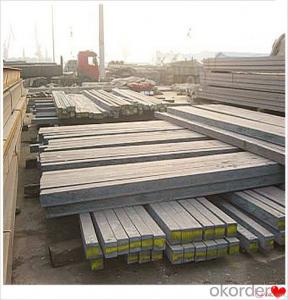

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How are tool steels used in the manufacturing of cutting tools?

- Tool steels are widely used in the manufacturing of cutting tools due to their excellent hardness, wear resistance, and toughness properties. These steels are specifically designed to withstand high temperatures, intense pressures, and repetitive impacts during cutting operations. Tool steels are utilized to make various cutting tools such as drills, milling cutters, saw blades, and dies. They provide the necessary strength and durability required for cutting, shaping, and forming various materials including metals, plastics, and wood. Additionally, tool steels can be heat treated to further enhance their hardness and wear resistance, ensuring a longer lifespan and improved performance of cutting tools.

- Q: How does special steel perform in high-stress environments?

- Special steel is designed specifically for high-stress environments, excelling in various forms of stress, including mechanical, thermal, and chemical stress. What sets it apart is its distinct composition and manufacturing process, resulting in exceptional resistance to stress. One of the standout features of special steel is its remarkable tensile strength. It can withstand immense pressure without deforming or failing. This strength is achieved by incorporating alloying elements like chromium, nickel, and molybdenum, which enhance its structural integrity and toughness. These elements also enhance the steel's resistance to corrosion and oxidation, ensuring its durability and reliability in harsh conditions. Additionally, special steel exhibits superb fatigue resistance, enabling it to endure repetitive and cyclic loading without developing cracks or fractures. This quality is crucial in high-stress environments where components are constantly subjected to vibrations or cyclic loading, such as in aerospace, automotive, and industrial applications. Not only does special steel possess impressive mechanical properties, but it also boasts exceptional resistance to extreme temperatures. It retains its strength and integrity even at elevated temperatures, making it suitable for use in high-temperature environments like power plants, furnaces, and chemical processing industries. Furthermore, special steel excels in wear resistance, enabling it to withstand abrasive conditions encountered in mining, construction, or manufacturing processes. This reduces the need for frequent maintenance or replacement, resulting in cost savings and increased productivity. In conclusion, special steel's outstanding performance in high-stress environments can be attributed to its unique combination of strength, durability, corrosion resistance, fatigue resistance, temperature resistance, and wear resistance. Its ability to withstand extreme conditions makes it the ideal choice for critical applications where reliability and safety are of utmost importance.

- Q: How does special steel contribute to the production of precision instruments?

- Special steel contributes to the production of precision instruments by providing the necessary strength, durability, and resistance to corrosion. Its unique properties allow for the manufacturing of intricate components with tight tolerances, ensuring the precision instruments function accurately and reliably.

- Q: How does special steel contribute to the telecommunications equipment industry?

- Special steel plays a crucial role in the telecommunications equipment industry by providing the necessary strength, durability, and reliability to support the complex infrastructure and advanced technologies involved in this sector. One significant contribution of special steel is its ability to withstand extreme weather conditions and environmental factors. Telecommunications equipment, such as transmission towers, antennas, and satellites, are often exposed to harsh elements like strong winds, heavy rain, and even earthquakes. Special steel, with its high tensile strength and resistance to corrosion, ensures the stability and longevity of the infrastructure, minimizing the risk of damage or failure. Moreover, special steel is employed in the production of various components used in telecommunications equipment. These components include connectors, cables, and electronic enclosures, which require materials with excellent electrical conductivity and heat dissipation properties. Special steel alloys, such as stainless steel or nickel-based alloys, are utilized to meet these requirements, ensuring efficient transmission of signals and preventing overheating issues. In addition, special steel is crucial for the manufacturing of high-quality tools and equipment used in the installation, maintenance, and repair of telecommunications networks. Specialized steel alloys, like tool steel, offer exceptional hardness, toughness, and wear resistance, enabling the production of reliable and long-lasting tools. These tools are essential for professionals working in the telecommunications industry, as they allow them to efficiently and accurately install and maintain the equipment, ensuring uninterrupted connectivity for end-users. Furthermore, as the telecommunications industry continues to evolve, special steel plays a vital role in supporting the deployment of advanced technologies like 5G networks and fiber-optic systems. These technologies require specialized components, such as waveguides, reflectors, and amplifiers, which are often made from special steel alloys to ensure optimal performance and durability. By providing the necessary materials for these cutting-edge technologies, special steel contributes to the expansion and improvement of telecommunications infrastructure worldwide. In conclusion, special steel is indispensable to the telecommunications equipment industry by offering the strength, durability, and reliability required for the infrastructure, components, tools, and advanced technologies involved in this sector. Its unique properties enable the industry to provide efficient and uninterrupted communication services to individuals and businesses globally.

- Q: What is the significance of tensile strength in special steel?

- Tensile strength is of great significance in special steel because it determines the steel's ability to withstand stretching or pulling forces without breaking or deforming. This property is crucial in various industries, especially in manufacturing and construction, where high tensile strength is required for structural integrity and safety. Special steel with superior tensile strength can withstand heavy loads, resist impacts, and provide durability, making it highly sought after in applications such as building infrastructure, automotive manufacturing, and aerospace engineering.

- Q: How does special steel contribute to the heat resistance of products?

- Special steel contributes to the heat resistance of products due to its unique properties and composition. It is specifically designed to withstand high temperatures without losing its strength or structural integrity. The inclusion of elements such as chromium, nickel, and molybdenum in special steel enhances its heat resistance by forming a protective oxide layer that prevents oxidation and corrosion at elevated temperatures. This enables products made with special steel to withstand extreme heat conditions, making them suitable for various applications in industries such as aerospace, automotive, and energy.

- Q: Can special steel be used in the medical industry?

- Yes, special steel can be used in the medical industry. It is commonly employed in the production of surgical instruments, medical implants, and equipment due to its high strength, corrosion resistance, and biocompatibility. Special steel alloys, such as stainless steel and titanium alloys, are extensively utilized in various medical applications to ensure patient safety and enhance the effectiveness of medical procedures.

- Q: What are the cutting tools used for machining special steel?

- The cutting tools used for machining special steel include carbide inserts, high-speed steel (HSS) tools, ceramic tools, and diamond-coated tools. These tools are designed to withstand the high temperatures and hardness of special steels, ensuring efficient and precise cutting operations.

- Q: What are the properties of high-strength steel?

- High-strength steel has several key properties that make it desirable for various applications. It possesses exceptional strength, allowing it to withstand heavy loads and resist deformation under stress. It also exhibits excellent toughness, meaning it can absorb energy without fracturing. Additionally, high-strength steel typically offers high hardness, good wear resistance, and enhanced corrosion resistance. Its properties make it ideal for use in industries such as automotive, aerospace, construction, and manufacturing, where durability and reliability are crucial.

- Q: How does special steel contribute to the defense industry?

- Special steel contributes to the defense industry by providing materials with exceptional strength, durability, and resistance to wear, corrosion, and extreme temperatures. These properties make it ideal for manufacturing military equipment, such as tanks, aircraft, submarines, and artillery, ensuring their reliability and long service life. Additionally, special steel's high hardness and toughness make it suitable for producing armor plates and ballistic protection systems, enhancing the safety and survivability of military personnel.

Send your message to us

Prime Newly 3SP CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords