Blast Furnace 5SP CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description of Blast Furnace 5SP CNBM Steel Billets with High Quality

| GRADE | SIZE | APPLICATION |

| 5SP | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Blast Furnace 5SP CNBM Steel Billets with High Quality

| 5SP | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.28-0.37 | 0.15-0.30 | 0.50-0.80 | 0.040% Max | 0.05Max |

Company Information of Blast Furnace 5SP CNBM Steel Billets with High Quality:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery for Blast Furnace 5SP CNBM Steel Billets with High Quality

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

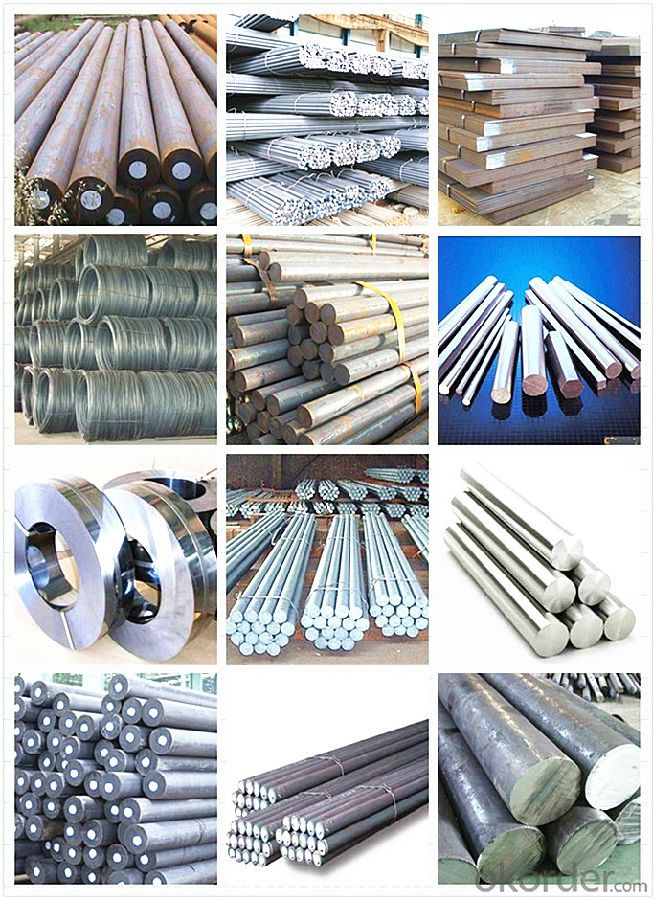

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the challenges in manufacturing special steel?

- Some of the challenges in manufacturing special steel include the high cost of raw materials, the complex and precise production processes, ensuring consistent quality and performance, meeting specific customer requirements, and staying up-to-date with rapidly advancing technologies and industry standards. Additionally, the demand for customization and shorter lead times can also present challenges in terms of production planning and logistics.

- Q: How does special steel perform in terms of corrosion resistance in marine environments?

- Special steel alloys, specifically designed for marine environments, exhibit excellent corrosion resistance. Due to their higher levels of alloying elements like chromium, nickel, and molybdenum, these steels form a protective oxide layer that prevents rusting and pitting, even when exposed to saltwater and other harsh marine conditions. Their exceptional corrosion resistance ensures prolonged durability, reduced maintenance, and enhanced performance in marine environments.

- Q: Is special steel magnetic?

- Yes, special steel can be magnetic. The magnetism of steel depends on its composition and the presence of certain elements, such as iron, nickel, and cobalt. Special steels that contain these magnetic elements can exhibit magnetic properties. However, not all types of steel are magnetic. Some stainless steels, for example, have a higher content of non-magnetic elements like chromium, which reduces their magnetic properties. So, whether a specific type of special steel is magnetic or not will depend on its composition.

- Q: How does the composition of special steel affect its mechanical properties?

- The mechanical properties of special steel are significantly influenced by its composition. Special steel refers to a type of steel that has been altered or mixed with other elements to enhance its strength, toughness, hardness, and other desirable properties. The mechanical properties of special steel can be greatly affected by the addition of various alloying elements, such as manganese, chromium, nickel, molybdenum, vanadium, and tungsten. For instance, the inclusion of chromium can enhance corrosion resistance and hardness, making the steel more suitable for use in harsh environments. Manganese is often added to improve the steel's hardenability and tensile strength. Nickel can increase toughness and strength while maintaining good ductility. The specific mechanical properties of special steel can be achieved by adjusting the amount and combination of these alloying elements. For example, increasing the carbon content can boost the steel's strength and hardness, but it may reduce its ductility. Conversely, reducing the carbon content and introducing elements like nickel and molybdenum can enhance the steel's toughness and resistance to impacts. Moreover, the heat treatment process is crucial in influencing the mechanical properties of special steel. Techniques like quenching and tempering allow for the manipulation of the steel's microstructure to attain desired properties. Quenching involves rapidly cooling the steel to achieve high hardness and strength, while tempering helps reduce brittleness and improve toughness. In conclusion, the mechanical properties of special steel are determined by its composition, including the type and quantity of alloying elements, as well as the heat treatment process. By carefully selecting and controlling these factors, manufacturers can customize special steel to meet specific performance requirements for a wide range of applications.

- Q: What are the main applications of special steel in the electronics packaging?

- Special steel is widely used in electronics packaging due to its unique properties. The main applications of special steel in electronics packaging include providing high strength and durability to protect delicate electronic components, offering excellent corrosion resistance to safeguard against environmental factors, and ensuring thermal conductivity for efficient heat dissipation. Additionally, special steel is utilized in creating precise and intricate shapes for components, ensuring electromagnetic compatibility, and providing electrical conductivity for improved performance and reliability in electronic devices.

- Q: What are the different types of special steel?

- There are several types of special steel, including stainless steel, tool steel, high-speed steel, carbon steel, alloy steel, and maraging steel. These different types of special steel are designed to possess specific properties and characteristics that make them suitable for various applications across industries such as construction, automotive, aerospace, and manufacturing.

- Q: What are the different forging techniques for special steel?

- There are several different forging techniques used for special steel, including open die forging, closed die forging, and ring rolling. Open die forging involves shaping the steel between flat dies or anvils, while closed die forging uses shaped dies to compress the steel into the desired shape. Ring rolling involves shaping the steel by rolling it between two or more dies, creating a seamless ring shape. Each forging technique has its own advantages and is chosen based on the specific requirements of the steel product being produced.

- Q: What are the properties of corrosion-resistant alloy steel?

- Corrosion-resistant alloy steel possesses properties such as high resistance to corrosion, excellent strength, durability, and the ability to withstand harsh environmental conditions. It is resistant to rust, corrosion, and oxidation, making it ideal for applications in industries such as marine, chemical, and oil and gas. The alloy steel also offers good mechanical properties, including high tensile strength and toughness, which ensures its long-term performance and reliability.

- Q: What are the different methods of hardening special steel?

- There are several different methods of hardening special steel, including heat treatment, quenching, tempering, and carburizing. Heat treatment involves heating the steel to a specific temperature and then cooling it rapidly to increase its hardness. Quenching involves rapidly cooling the heated steel in a liquid, such as oil or water, to achieve high hardness. Tempering is a process that follows quenching, where the steel is reheated to a lower temperature to reduce brittleness and increase toughness. Carburizing is a method where the steel is heated in a carbon-rich environment to increase its surface hardness by infusing carbon atoms into the outer layer. These methods can be used individually or in combination to achieve desired hardness levels in special steel.

- Q: What is the significance of alloying elements in special steel?

- Alloying elements play a crucial role in special steel as they enhance the mechanical properties, corrosion resistance, and overall performance of the steel. These elements are added in specific proportions to alter the microstructure and create desired properties such as increased strength, hardness, toughness, and heat resistance. Additionally, alloying elements can improve the steel's ability to withstand extreme conditions, such as high temperatures or corrosive environments. Overall, the presence of alloying elements in special steel allows for the production of tailor-made materials that meet specific application requirements in industries such as automotive, aerospace, and construction.

Send your message to us

Blast Furnace 5SP CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords