Spring Strip Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 500000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Spring Steel:

Spring steel is divided into two types, one is alloy spring steel, and other one is carbon spring steel.

Alloy spring steel is a type that is used for manufacturing springs and other elastic parts. Spring steel should have high ratio of yield strength and tensile strength and elastic limit to make sure that the springs obtain enough power of elastic deformation and can bear much load.

Types of alloy spring steel: Si-Mn spring steel, Si-Cr spring steel, Cr-Mn Spring steel, Cr-V spring steel and so on.

Specification of Spring Strip Steel:

-Material: 30W4Cr2VA

-Standard: GB/T 1222-2007

-Type: Spring Steel

Chemical Composition:

C | Si | Mn | S |

0.26~0.34 | 0.17~0.37 | ≤0.40 | ≤0.030 |

P | Cr | Ni | Cu |

≤0.030 | 2.00~2.50 | ≤0.35 | ≤0.25 |

V | W | ||

0.50~0.80 | 4.00~4.50 |

Mechanical Properties:

-Yield Strength σs (MPa): ≥1470 (150)

-Elongation δ10(%):≥7

-Hardness:

1, Hot rolled + Heat treatment, ≤321HB

2, Cold drawn + Heat treatment: ≤321HB

-Impact Power: ≥40

Norm of heat treatment:

1, Quenching: 1050℃~1100℃.

2, Cooled by oil.

3, Tempering: 600℃±50℃.

Usage/Applications of Spring Strip Steel:

-Due to the elements W, Cr and V, this type of spring steel obtain pretty high hardenability and nice mechanical properties under room temperature and high temperature. The tempering stability and hot workability are good.

-Being used under the state of quenching and high temperature tempering. It’s usually used as heat-resisting springs with working temperature below 500℃, like main secure valve spring of furnace and turbine steam seal leaf springs.

Packaging & Delivery of Spring Strip Steel:

-Packing Detail: The products will be well packed.

-Marks: there are two types of marks.

1, Tag marks. To show customers the specifications of products, company name and logo and other information required by customers.

2, Color marks. It’s easy for customers to distinguish them from other products at destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

Payment:

-Theoretical weight/Actual weight.

-FOB, CFR or CIF.

-Terms of payment: T.T. or L/C at sight.

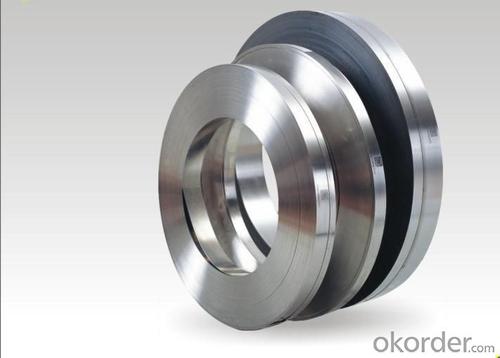

Photos of Spring Strip Steel:

- Q: What are the different methods of testing special steel for quality assurance?

- There are several methods of testing special steel for quality assurance, including mechanical testing, chemical analysis, non-destructive testing, and metallographic analysis. Mechanical testing involves measuring the steel's strength, hardness, and toughness through techniques such as tensile testing, impact testing, and hardness testing. Chemical analysis helps determine the composition and impurities in the steel through methods like spectroscopy and elemental analysis. Non-destructive testing methods like ultrasonic testing, magnetic particle testing, and radiographic testing are used to detect any defects or flaws in the steel without causing damage. Metallographic analysis involves examining the steel's microstructure through techniques like optical microscopy and electron microscopy to assess its internal structure and identify any potential issues.

- Q: Can special steel be used in the construction industry?

- Yes, special steel can be used in the construction industry. It offers several advantages such as high strength, durability, and resistance to corrosion, making it suitable for various applications in construction, including beams, columns, and reinforced concrete structures. Special steel can also provide cost-effective solutions by reducing the need for additional materials and maintenance.

- Q: What are the different types of wear-resistant steel?

- There are several types of wear-resistant steel, including AR400, AR450, AR500, and Hardox. These steels are specifically designed to withstand abrasion, impact, and wear in various applications such as mining, construction, and manufacturing.

- Q: What are the main characteristics of electrical steel?

- Electrical steel, also known as silicon steel or transformer steel, offers several key features that make it suitable for use in electrical appliances and power equipment. Firstly, it possesses a high magnetic permeability, enabling efficient magnetic flux conduction and reducing energy losses in transformers, motors, and generators. Secondly, electrical steel demonstrates low core loss, encompassing hysteresis loss and eddy current loss. Hysteresis loss refers to the dissipation of energy caused by the reversal of magnetic domains within the material, while eddy current loss arises from circulating currents induced by alternating magnetic fields. The low core loss property of electrical steel ensures high energy efficiency and minimizes heat generation in electrical devices. Another significant characteristic of electrical steel is its high electrical resistivity, which diminishes the magnitude of eddy currents and further reduces energy losses in electrical equipment. Additionally, it possesses a high saturation induction, denoting its ability to reach maximum magnetic flux density. This characteristic enables transformers and motors to function at higher magnetic flux densities, resulting in more compact and efficient designs. Moreover, electrical steel exhibits high mechanical strength, essential for withstanding the stresses and vibrations encountered in electrical devices. It also demonstrates good thermal conductivity, facilitating efficient heat dissipation and enhancing the overall performance and longevity of electrical equipment. In conclusion, electrical steel boasts high magnetic permeability, low core loss, high electrical resistivity, high saturation induction, high mechanical strength, and good thermal conductivity. These properties make it an ideal material for various electrical applications, offering efficiency, reliability, and performance in power generation, transmission, and utilization.

- Q: What are the different non-destructive testing methods for special steel?

- Special steel materials can be evaluated using a variety of non-destructive testing methods. These methods are specifically designed to identify flaws or defects in the steel without causing any harm to the material itself. There are several commonly used non-destructive testing methods for special steel: 1. Ultrasonic Testing (UT): UT utilizes high-frequency sound waves to detect internal flaws or defects in the steel. By directing ultrasonic waves into the material and analyzing the reflected waves, any cracks, voids, or inclusions can be identified. 2. Magnetic Particle Testing (MT): MT is primarily used to identify surface defects in steel. By applying a magnetic field to the material and iron particles to the surface, any present defects will cause the particles to cluster around them, making them visible for inspection. 3. Liquid Penetrant Testing (PT): PT is a widely used method to detect surface defects in special steel. This technique involves applying a liquid dye to the steel surface and removing excess dye after a certain amount of time. By then applying a developer, any dye drawn out of defects becomes visible for inspection. 4. Radiographic Testing (RT): RT utilizes X-rays or gamma rays to examine the internal structure of special steel. The steel is exposed to radiation, and the resulting image is captured on a radiographic film or digital detector. This method is highly effective in detecting internal defects such as porosity, inclusions, or cracks. 5. Eddy Current Testing (ECT): ECT is primarily used for surface inspection of special steel. It involves passing an electrical current through a coil, generating a magnetic field. Any variations in the magnetic field caused by defects on the surface of the steel can be detected and analyzed. These non-destructive testing methods provide valuable information about the quality and integrity of special steel materials without causing any damage. By implementing these techniques, manufacturers and engineers can ensure that the steel meets required standards and specifications, ultimately enhancing safety and reliability in various applications.

- Q: What are the main factors affecting the impact toughness of special steel?

- The impact toughness of special steel, or any material for that matter, is influenced by various factors. Some of the main factors affecting the impact toughness of special steel are: 1. Composition: The chemical composition of the steel plays a significant role in determining its impact toughness. Elements such as carbon, manganese, silicon, nickel, and molybdenum can be added to enhance the toughness of the steel. Higher carbon content generally improves hardness but reduces toughness, while alloying elements like nickel and molybdenum can enhance toughness. 2. Heat treatment: The heat treatment process, including processes like quenching and tempering, can significantly affect the impact toughness of special steel. Proper heat treatment can refine the microstructure of the steel, making it more resistant to fractures and increasing its toughness. 3. Microstructure: The microstructure of the steel, including the size, shape, and distribution of its grains, greatly impacts its toughness. Fine-grained steels generally exhibit better toughness compared to coarse-grained ones. The presence of certain phases, such as martensite or bainite, can also affect the impact toughness. 4. Inclusions: The presence of non-metallic inclusions, such as sulfides, oxides, or carbides, in the steel can act as stress concentration points and reduce its impact toughness. High-quality special steels often undergo processes like vacuum degassing or electroslag remelting to minimize the presence of these inclusions. 5. Processing conditions: The manufacturing processes used to produce special steel can influence its impact toughness. Factors such as forging, rolling, or extrusion conditions, as well as the cooling rate during solidification, can affect the microstructure and, consequently, the toughness of the steel. 6. Temperature: The impact toughness of special steel also varies with temperature. Some steels exhibit good toughness at low temperatures, while others may have better performance at higher temperatures. The temperature at which the steel is used or tested is an important factor to consider when evaluating its impact toughness. It is worth noting that the impact toughness of special steel is often determined using standardized tests, such as the Charpy or Izod test, which involve subjecting a notched specimen to impact loading. These tests provide valuable information on the material's ability to absorb energy and resist fracture under impact conditions.

- Q: Can special steel be used in the plumbing industry?

- Yes, special steel can be used in the plumbing industry. It is often used in the manufacturing of pipes, fittings, and other components due to its high strength, corrosion resistance, and durability. Special steel, such as stainless steel or galvanized steel, is preferred for plumbing applications where longevity and resistance to corrosion are desired.

- Q: How is corrosion-resistant steel different from regular steel?

- Corrosion-resistant steel, also known as stainless steel, is different from regular steel due to its composition and properties. Unlike regular steel, which is primarily made of iron and carbon, corrosion-resistant steel contains high amounts of chromium and other alloying elements. These additional elements create a protective layer on the surface of the steel, making it resistant to corrosion caused by exposure to moisture, chemicals, and other environmental factors. Regular steel, on the other hand, is more prone to rusting and corrosion, requiring additional protective coatings or treatments to prevent degradation.

- Q: How does special steel perform in corrosive environments?

- Special steel is specifically designed to perform well in corrosive environments. It is made with a higher content of alloying elements such as chromium, which forms a protective oxide layer on the surface of the steel. This oxide layer acts as a barrier, preventing the steel from coming into direct contact with the corrosive elements in the environment. Additionally, special steel may also contain other alloying elements such as molybdenum, nickel, or copper, which further enhance its resistance to corrosion. These elements help to increase the steel's ability to withstand pitting, crevice corrosion, and stress corrosion cracking, which are common types of corrosion that occur in corrosive environments. Furthermore, special steel is often treated with various surface coatings or finishes that provide additional protection against corrosion. These coatings can include zinc, epoxy, or polymeric materials, which create an additional barrier between the steel and the corrosive elements. In summary, special steel performs exceptionally well in corrosive environments due to its high content of alloying elements, protective oxide layer, and additional surface coatings. It offers excellent resistance to various forms of corrosion and ensures the longevity and reliability of structures or equipment operating in such environments.

- Q: How does tungsten contribute to the properties of special steel?

- Tungsten contributes to the properties of special steel by improving its hardness, strength, and resistance to wear and corrosion. It also enhances the steel's ability to retain its shape and withstand high temperatures, making it suitable for various industrial applications such as cutting tools, electrical contacts, and parts for aerospace and automotive industries.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

Spring Strip Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 500000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords