Prime Quality Q195/215 CNBM Steel Billets with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

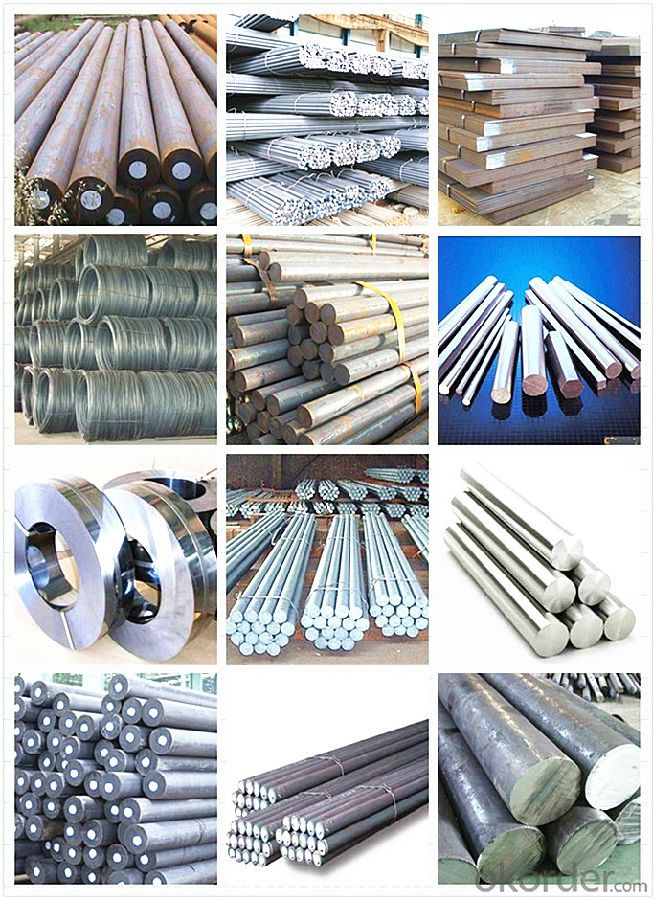

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the challenges in manufacturing special steel?

- Some of the challenges in manufacturing special steel include the high cost of raw materials, the complex and precise production processes, ensuring consistent quality and performance, meeting specific customer requirements, and staying up-to-date with rapidly advancing technologies and industry standards. Additionally, the demand for customization and shorter lead times can also present challenges in terms of production planning and logistics.

- Q: How does special steel perform in terms of corrosion resistance?

- Special steel has excellent corrosion resistance due to its high content of alloying elements, such as chromium, nickel, and molybdenum. These elements form a protective layer on the surface of the steel, preventing corrosive substances from reaching the underlying metal. Additionally, special steel can be further enhanced with surface treatments or coatings to enhance its resistance to corrosion in harsh environments.

- Q: How does special steel perform in impact loading conditions?

- Special steel is known for its exceptional performance in impact loading conditions. Due to its unique composition and manufacturing process, special steel exhibits remarkable strength, toughness, and resistance to deformation. When subjected to impact loading, special steel can effectively absorb and dissipate the energy generated, minimizing the risk of catastrophic failure or damage. The high strength of special steel allows it to withstand high impact forces without undergoing significant deformation or fracture. This characteristic makes it particularly suitable for applications where impact loading is prevalent, such as in the construction of heavy machinery, automotive components, and structural elements. Special steel's toughness is another crucial factor in its performance during impact loading conditions. It possesses excellent fracture toughness, enabling it to resist crack propagation and absorb impact energy without fracturing. This property ensures that special steel can withstand sudden and severe impacts without compromising its structural integrity. Additionally, special steel is often treated to enhance its resistance to impact loading conditions further. Processes such as heat treatment, forging, and quenching and tempering can increase the material's hardness and strength, making it even more capable of withstanding impact forces. In summary, special steel performs exceptionally well in impact loading conditions due to its high strength, toughness, and resistance to deformation. Its ability to absorb and dissipate energy efficiently, coupled with its resistance to fracture, makes it an ideal choice for applications where impact loading is a concern.

- Q: How does special steel perform in dynamic loading conditions?

- Special steel performs exceptionally well in dynamic loading conditions. It has high strength, toughness, and fatigue resistance, making it capable of withstanding repeated loading and impacts without failure. Its ability to absorb and distribute stress evenly helps prevent cracks and fractures, ensuring the structural integrity of components even under demanding, dynamic loading conditions.

- Q: What are the different coating techniques used for special steel?

- Some of the different coating techniques used for special steel include hot-dip galvanizing, electroplating, powder coating, and metallizing.

- Q: How does special steel withstand extreme temperatures?

- Special steel is designed to withstand extreme temperatures due to its unique composition and manufacturing process. It contains a higher percentage of alloying elements, such as chromium, nickel, and molybdenum, which enhance its heat resistance properties. These alloys form a protective layer on the surface of the steel, preventing oxidation and corrosion at high temperatures. Additionally, special steel undergoes specific heat treatment methods, such as quenching and tempering, which further enhance its ability to withstand extreme temperatures without losing its strength and structural integrity.

- Q: What are the different machining techniques for special steel?

- There are several different machining techniques that can be used for special steel, depending on the specific requirements and characteristics of the steel. Some common machining techniques for special steel include turning, milling, drilling, grinding, and broaching. Each technique has its own advantages and is used to achieve different results, such as shaping the steel, removing material, or creating precise cuts and finishes. The choice of machining technique will depend on factors such as the desired outcome, the hardness and toughness of the steel, and the complexity of the part being machined.

- Q: How does tool steel maintain its hardness at high temperatures?

- Tool steel maintains its hardness at high temperatures due to its high carbon content and the presence of alloying elements such as tungsten, molybdenum, and vanadium. These elements form carbides, which enhance the steel's ability to retain its hardness even under extreme heat. Additionally, the steel's fine grain structure and heat treatment processes contribute to its high temperature hardness retention.

- Q: How does special steel resist corrosion?

- Special steel resists corrosion due to the presence of specific alloying elements, such as chromium or nickel, which form a protective layer on the surface of the steel. This layer acts as a barrier, preventing oxygen and moisture from reaching the underlying steel and thus preventing the formation of rust or corrosion.

- Q: How is special steel used in the mining supply chain?

- Special steel is used extensively in the mining supply chain due to its exceptional strength, durability, and resistance to corrosion. It is utilized in various equipment and machinery used for exploration, extraction, processing, and transportation of minerals. Special steel is commonly employed in mining tools, drill bits, conveyor systems, crushers, grinding mills, and pumps, ensuring efficient and reliable operations in challenging mining environments.

Send your message to us

Prime Quality Q195/215 CNBM Steel Billets with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords