Low Price Steel Billets 3sp 5sp for Sale/Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Item: steel billets

Material Grade: Q195/Q235/Q275/Q345/3SP/5SP/20MnSi

Standards: GB, ASTM, BS, EN, JIS

Technique: hot rolled

Shape: Square

Size: 120mm*120mm, 150mm*150mm

Length: 6m/12m

Bending: No more than 5mm in 1 meter, No more than 30mm in 6 meter, No more than 60mm in 12 meter

Angular Twist: No more than 1 degree per meter and not more than 6 degree over 12 meter length.

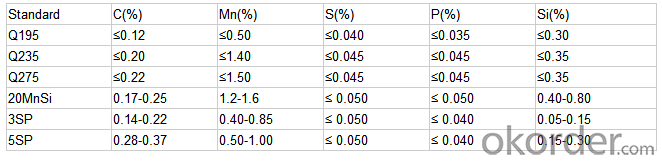

Chemical Composition:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

3)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Hot Rolled Square Steel Billet/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the applications of alloy steel in the aerospace industry?

- Alloy steel finds various applications in the aerospace industry due to its exceptional strength, durability, and resistance to corrosion and high temperatures. It is extensively used in the manufacturing of aircraft components such as landing gears, engine parts, turbine blades, and structural elements. The high strength-to-weight ratio of alloy steel allows for lighter and more fuel-efficient aircraft designs, while its ability to withstand extreme conditions ensures the safety and reliability of aerospace systems.

- Q: What are the different types of steel tanks and vessels available?

- There are several types of steel tanks and vessels available, including storage tanks, pressure vessels, mixing tanks, fermentation vessels, and process tanks. These tanks and vessels vary in terms of their design, shape, and purpose, but they all utilize steel as the primary material for their construction due to its strength and durability.

- Q: What are the different types of steel stair treads and nosings?

- There are several types of steel stair treads and nosings available, including diamond plate treads, serrated treads, perforated treads, and abrasive nosings. Each type offers specific benefits such as slip resistance, durability, and ease of maintenance, catering to various safety and aesthetic requirements in different environments.

- Q: What are the uses of steel in the manufacturing of household appliances?

- Steel is commonly used in the manufacturing of household appliances due to its durability, strength, and heat resistance properties. It provides the necessary structural support for appliances such as refrigerators, stoves, and washing machines. Additionally, steel's ability to withstand high temperatures makes it suitable for appliances that generate heat, such as ovens and irons. Its corrosion resistance also ensures longevity and reduced maintenance requirements for these appliances. Overall, steel enhances the performance, reliability, and longevity of household appliances.

- Q: How are steel products used in the construction of religious buildings and places of worship?

- Steel products are commonly used in the construction of religious buildings and places of worship due to their strength, durability, and versatility. They are utilized in various structural components, such as beams, columns, and trusses, to provide stability and support to the entire structure. Steel is also used for roofing, cladding, and facade systems, offering protection against weather elements while adding aesthetic appeal. Additionally, steel is used in the construction of stairs, railings, and decorative elements, enhancing the overall design and functionality of religious buildings.

- Q: What are the advantages of using steel products in the automotive industry?

- There are several advantages of using steel products in the automotive industry. Firstly, steel is a highly durable and strong material, providing robustness and ensuring safety in the event of accidents or collisions. Secondly, steel is readily available and cost-effective, making it a cost-efficient choice for automakers. Additionally, steel is easily recyclable, contributing to sustainability efforts and reducing the environmental impact of the automotive industry. Lastly, steel's versatility allows for various shapes and sizes, accommodating the diverse design requirements of different vehicle components. Overall, the use of steel products in the automotive industry offers durability, cost-effectiveness, sustainability, and design flexibility.

- Q: How does steel sheet metal welding and joining work?

- Steel sheet metal welding and joining works by using various techniques to permanently join two or more pieces of steel sheet metal together. This can be achieved through processes such as arc welding, resistance welding, or laser welding. These methods involve creating a localized heat source to melt the edges of the metal sheets, which are then fused together to form a strong and durable bond. The welding process may also involve the use of a filler material, such as a welding wire or rod, to reinforce the joint and improve its strength. Overall, steel sheet metal welding and joining is a crucial process in the fabrication of structures and products made from steel, ensuring their integrity and functionality.

- Q: What are the advantages of using steel in automotive manufacturing?

- There are several advantages to using steel in automotive manufacturing. Firstly, steel is incredibly strong and durable, making it an ideal material for building the frame and structure of vehicles. This enhances the safety of the vehicle and provides better protection for passengers in the event of a collision. Additionally, steel is readily available and cost-effective, making it a cost-efficient choice for automakers. Furthermore, steel is highly recyclable, which aligns with the growing emphasis on sustainability and reducing the environmental impact of manufacturing processes. Overall, using steel in automotive manufacturing provides strength, safety, affordability, and sustainability benefits.

- Q: What are the different types of steel channels and their uses?

- There are several types of steel channels, including C channels, U channels, and J channels. C channels are commonly used for structural applications, such as supporting beams or framing. U channels are often used for edging or trim applications, as well as for framing windows or doors. J channels are primarily used in the construction industry for siding or trim installation, providing a clean finish and protecting against moisture.

- Q: What is the impact of steel imports on the domestic steel industry?

- The impact of steel imports on the domestic steel industry can be both positive and negative. On one hand, steel imports can provide access to a wider variety of steel products, potentially reducing costs and increasing competitiveness. On the other hand, a surge in steel imports can threaten the domestic industry by causing job losses, reduced production, and financial strain on local steel producers. The impact ultimately depends on the balance between imports and domestic production, as well as government policies and measures taken to protect the domestic steel industry.

Send your message to us

Low Price Steel Billets 3sp 5sp for Sale/Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords