Dental Floss Teeth Cleaning PTFE dental floss 50m

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 reel

- Supply Capability:

- 100000 reel/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

Brand OEM/Ok Floss

Floss materialTPFE

Floss length50m/OEM

WaxImport germany wax/american wax/bee wax/candelilla wax/customized wax

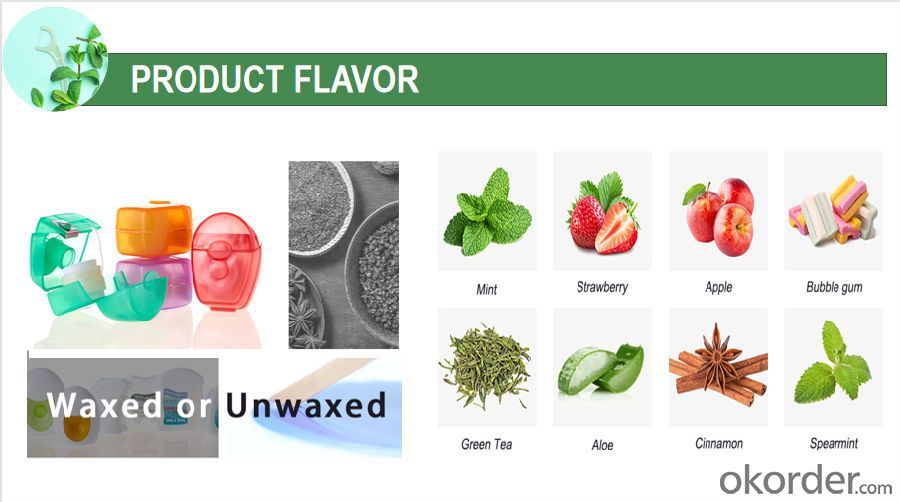

FlavorMint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss original color

Floss original colorIndividual bulk PP box/as customized

ApplicationsFamily,Hotel,Travel,Supermarket

DeliveryBy sea,By air,By express.

Lead time20-30days

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots

where your toothbrush can’t reach, generally between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

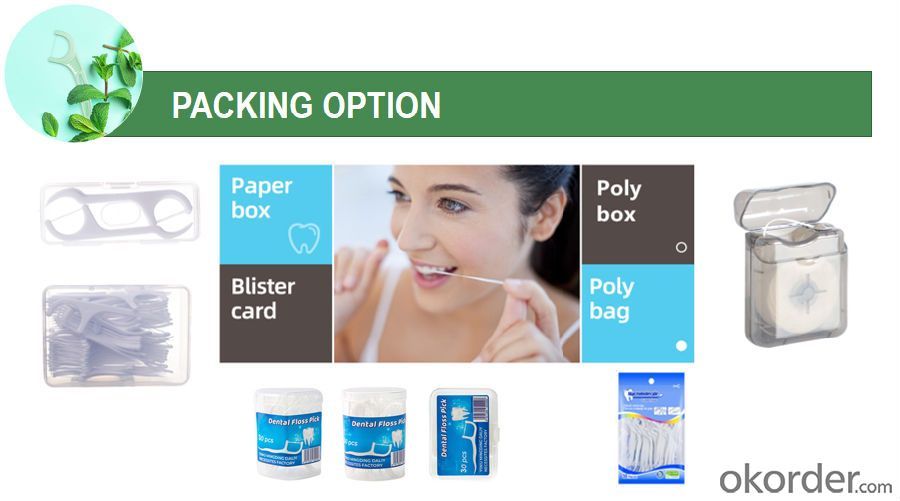

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: How is medical plastic used in wound closure devices?

- Medical plastic is commonly used in wound closure devices such as sutures, staples, and surgical tapes. It is used to create strong and flexible materials that can effectively close wounds, promoting healing and preventing infection. The plastic used in these devices is biocompatible, meaning it is safe to use in contact with the human body. It is also designed to minimize tissue trauma, reduce scarring, and provide a secure closure that keeps the wound edges together.

- Q: How is medical plastic used in burn care?

- Medical plastic is used in burn care in various ways. It is commonly used to create burn dressings and bandages that protect the burn area from infection, provide a barrier against further damage, and aid in the healing process. These dressings are often made from a special type of medical-grade plastic that is non-stick, flexible, and has antimicrobial properties. Additionally, medical plastic is also used to create specialized burn splints and supports that help immobilize and protect the burned area, promoting proper healing and reducing pain.

- Q: What are the factors affecting the biocompatibility of medical plastic?

- The factors affecting the biocompatibility of medical plastic include the chemical composition of the plastic material, its physical properties such as surface roughness and porosity, the presence of additives or impurities, and the body's immune response to the plastic. Additionally, factors such as sterilization methods, manufacturing processes, and the duration of contact between the plastic and the body can also influence its biocompatibility.

- Q: How is medical plastic used in ophthalmic applications?

- Medical plastic is used in ophthalmic applications to create various devices and equipment that are essential for the diagnosis, treatment, and management of eye conditions. It is used to manufacture contact lenses, intraocular lenses, surgical instruments, and implantable devices such as corneal implants or glaucoma drainage devices. The biocompatible nature of medical plastic makes it safe for use in direct contact with the eye, while its flexibility and transparency allow for comfortable and effective ophthalmic treatments.

- Q: Are there any potential risks associated with the release of microplastics from medical plastics?

- Yes, there are potential risks associated with the release of microplastics from medical plastics. These microplastics can enter the environment and accumulate in various ecosystems, potentially causing harm to marine life and other organisms. Additionally, there is a concern that these microplastics can enter the food chain, leading to potential health risks for humans. Research is ongoing to better understand the extent of these risks and develop strategies to minimize their impact.

- Q: How long does it take to sterilize the autoclave?

- The general 16 liter sterilizer belongs to hand elimination:The use of temperature is generally 121 degrees, half an hour or so, you can achieve sterilization effect.

- Q: How does medical plastic contribute to the development of drug-eluting devices?

- Medical plastic plays a crucial role in the development of drug-eluting devices by providing a biocompatible and versatile material for the fabrication of various components. It allows for controlled release of medication, ensuring optimal dose delivery and enhancing the therapeutic efficacy of these devices. Additionally, medical plastic offers excellent mechanical properties, ease of molding, and compatibility with different drugs, making it an ideal choice for drug-eluting devices, ultimately improving patient outcomes.

- Q: Can medical plastic be safely used in oncological applications?

- Yes, medical plastic can be safely used in oncological applications. Medical plastics are designed and manufactured to meet strict quality and safety standards. They are biocompatible, meaning they do not cause any harmful reactions when in contact with the human body. In oncological applications, medical plastic is commonly used in various medical devices such as syringes, catheters, and implantable devices. These materials provide the necessary functionality and durability while ensuring patient safety during oncological treatments and procedures.

- Q: How to remove the plastic flavor of the new thermos cup?

- Most of the new cups will have some flavor, such as the plastic taste in the plastic cups, the taste of logs in the paper cups, and the taste of the metal in the stainless steel cups, which brings a lot of trouble to the people. How should we eliminate the smell in the cup? Today, Xiao Bian asks the person in charge of the brand to tell us how to get rid of the peculiar smell when the new thermos cup is bought.

- Q: Can medical plastic be used in drug delivery implants?

- Yes, medical plastic can be used in drug delivery implants. Medical plastics, such as biodegradable polymers and drug-eluting materials, have been successfully utilized in the development of drug delivery implants. These implants can release medications gradually over time, providing targeted and sustained drug delivery to the desired site within the body.

Send your message to us

Dental Floss Teeth Cleaning PTFE dental floss 50m

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 reel

- Supply Capability:

- 100000 reel/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords