Correcting smell dental floss suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

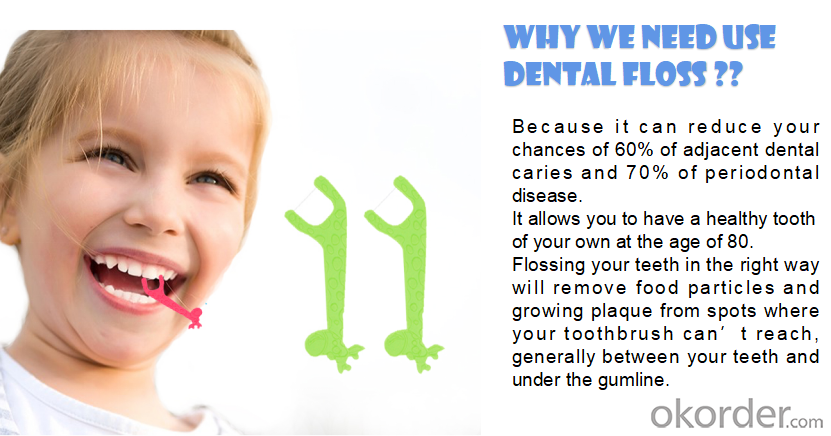

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Correcting smell dental floss suitable for children

| Brand | Ok Floss |

| Floss material | UHMWPE |

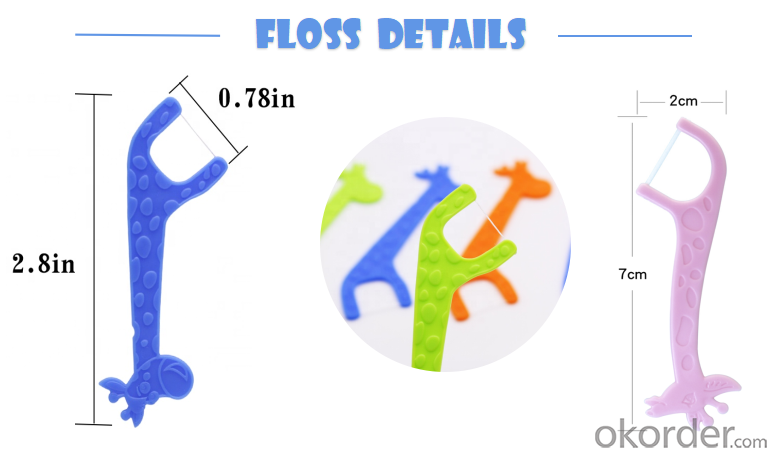

| Size | Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea /fruit |

| Color | white,yellow,orange |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Restaurant |

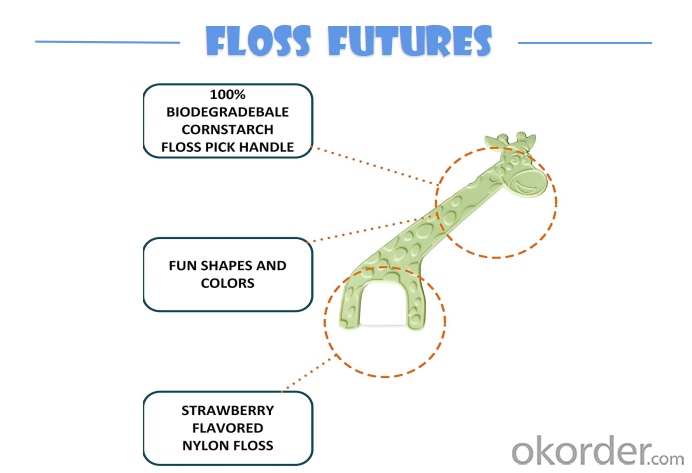

| Shape | Bear,Giraffe |

| Lead time | 20-30days |

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q: How does medical plastic help in diagnostic testing?

- Medical plastic plays a crucial role in diagnostic testing by providing a safe and sterile environment for various medical devices and instruments used in the process. It ensures the accuracy and reliability of test results by preventing contamination and maintaining the integrity of samples. Additionally, medical plastic can be easily molded into different shapes and sizes, allowing for the development of specialized diagnostic tools that enhance efficiency and precision in testing procedures.

- Q: Are there any concerns about the disposal of medical plastics?

- Yes, there are concerns about the disposal of medical plastics. Medical plastics can contain potentially hazardous substances, such as harmful chemicals or pathogens, which can pose risks to human health and the environment if not properly disposed of. Additionally, the improper disposal of medical plastics can contribute to plastic pollution and negatively impact ecosystems. Therefore, it is important to have proper protocols and regulations in place to ensure the safe and responsible disposal of medical plastics.

- Q: What are the mechanical properties of medical plastic?

- The mechanical properties of medical plastic typically include high strength, excellent toughness, and good impact resistance. Additionally, medical plastics often exhibit low friction, superior dimensional stability, and resistance to chemicals and sterilization processes.

- Q: Are there any potential risks associated with the release of toxic fumes from medical plastics?

- Yes, there are potential risks associated with the release of toxic fumes from medical plastics. Exposure to these fumes can lead to respiratory irritation, allergic reactions, and in some cases, long-term health complications. It is crucial to ensure proper ventilation and use of appropriate safety measures when handling or disposing of medical plastics to minimize these risks.

- Q: Are medical plastics biocompatible?

- Yes, medical plastics can be biocompatible. Biocompatibility refers to the ability of a material to safely interact with living tissues or organisms without causing harm or adverse reactions. Medical plastics are specifically designed and tested to be compatible with the human body, ensuring they are safe and well-tolerated when used in medical devices, implants, or other healthcare applications.

- Q: What are the latest advancements in medical plastic technology?

- Some of the latest advancements in medical plastic technology include the development of biocompatible and bioresorbable plastics, 3D printing of medical devices and implants, improved antimicrobial properties of plastic materials, and the use of nanotechnology to enhance the functionality and performance of medical plastics. These advancements have greatly improved patient care, surgical procedures, and medical device manufacturing.

- Q: What are the most common uses of medical plastics in radiography?

- The most common uses of medical plastics in radiography include the production of protective barriers, positioning aids, and imaging accessories. These plastics are often used to create radiation shields for both patients and healthcare professionals, ensuring their safety during X-ray procedures. Additionally, medical plastics are utilized to manufacture positioning aids, such as immobilization devices, which help patients maintain the correct posture during imaging. Various imaging accessories, like cassette holders and protective covers, are also made from medical plastics to enhance the efficiency and safety of radiography procedures.

- Q: Can medical plastics be used in diagnostic tools?

- Yes, medical plastics can be used in diagnostic tools. Medical-grade plastics are commonly used in the manufacturing of various diagnostic tools such as syringes, test tubes, pipettes, and even more complex devices like blood analyzers and imaging equipment. These plastics offer advantages such as being durable, lightweight, and resistant to chemicals and sterilization methods, making them suitable for use in diagnostic tools.

- Q: What are the considerations for selecting medical plastic for packaging?

- When selecting medical plastic for packaging, several considerations need to be taken into account. Firstly, the plastic material should be compatible with the medical product it is packaging, ensuring that it does not react chemically or contaminate the contents. The plastic should also provide a sufficient level of barrier properties to protect the product from external factors such as moisture, oxygen, and UV light. Additionally, the plastic should have appropriate mechanical properties, such as strength and flexibility, to withstand handling and transportation without compromising the integrity of the package. Furthermore, factors like regulatory compliance, cost-effectiveness, and sustainability should also be considered while selecting medical plastic for packaging.

- Q: Can medical plastics be reused?

- No, medical plastics cannot be reused due to the risk of contamination and the need for sterile conditions in medical settings.

Send your message to us

Correcting smell dental floss suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords