Dental floss with flavor of land animal shape suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental floss with flavor of land animal shape suitable for children

FLOSS FOR KIDS

| Brand: | OEM/Ok |

| Floss materia: | UHMWPE,Charcal as customized |

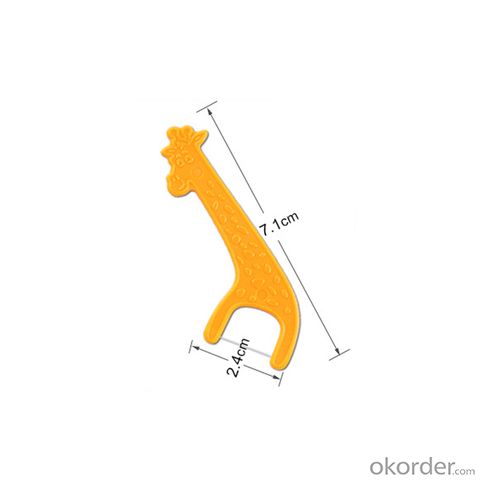

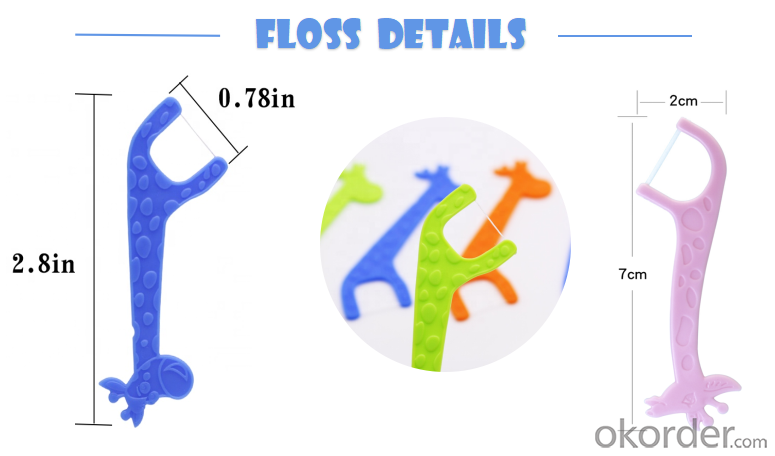

| Size | Length: 7.5cm |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Flavor |

| Color | yellow,white,blue,black |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Shape | Bear,Giraffe,Cola |

Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OEM SERVICE SMALL MOQ FACTORY PRICE HIGH QUALITY INTERNATIONAL CERTIFICATE

REDUCE ADJACENT DENTAL CARIES

FOOD-GRAD MATERIAL; FIBER FLOSS;MULBERRY SILK POLYACTIC ACID BAMBOO CHARCOAL

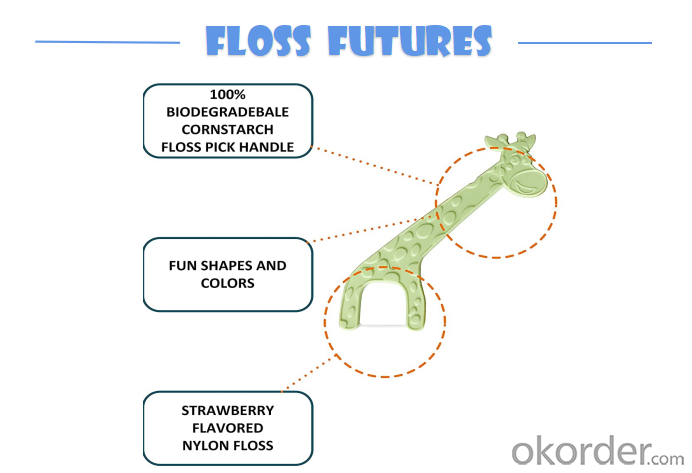

100% BIODEGRADEBALE CORNSTRACH FLOSS PICK HANDLE;FUN SHAPES AND COLORS STRAWBERRY FLAVORED NYLON FLOSS

Easilly slips between teeth ,without shredding, to comfortably remove plaque and help prevent gum disease

&

Good looking design protect children to hurt themselves

DENTAL FLOSS DETAILS & SIZE

COMFORT HANDLE;FOOD-GRAD MATERIALL;DENTAL FOR KIDS;FIBER FLOSS

DENTAL FOR KIDS

FACTORY PRICE & OEM

CERTIFICATIONS FDA CE ISO FSC

DENTAL FLOSS

GLOBAL MARKETING SERVICES

&

LOGISTIC SERVICE

&

EXPORT CREDIT INSURANCE SERVICES

&

FINANCIAL SERVICES

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

- Q: Injection molding products, down plastic powder, how to do?

- Find the source of dust, to prevent. Thoroughly clean the barrel and the injection machine

- Q: What are the advancements in transparent medical plastic materials?

- Advancements in transparent medical plastic materials include the development of high-performance polymers that offer improved clarity, strength, and biocompatibility for various medical applications. These materials now have enhanced resistance to chemicals, solvents, and sterilization methods, making them suitable for use in medical devices, such as surgical instruments, implants, and drug delivery systems. Furthermore, newer transparent medical plastics also exhibit lower levels of leachables and extractables, reducing the risk of adverse reactions in patients. Overall, these advancements have significantly improved the safety and efficacy of medical devices, allowing for better patient outcomes and healthcare practices.

- Q: Can medical alcohol be bottled in plastic?

- Yes, of course. Generally, glass bottles are used because alcohol bottles are anti-static

- Q: TPU plastic properties and injection molding process requirements

- 1, all kinds of machinery for special purpose (PU): corrosion resistance, hydrolysis resistance, wear-resistant PU polyether seals, diaphragm, oil seal Wang, etc.;2. Pu Pu board, rod, tube and belt;3, printing presses, copiers, textile machinery dedicated to all kinds of solvent rollers, wheels, etc., hardness in Shaw A60 to Shaw A98;4, industrial special (PU); wheel, forklift wheel, skateboard wheel, cigarette machine wheel, bearing wheel, drive wheel and so on;5, pump valve (PU); corrosion resistance, abrasion resistance, water resistance, methyl alcohol type valve lining, seals, couplings, diaphragm, noise elimination layer, floating ball and other products, can be made at low temperature (-40 degrees Celsius) products;

- Q: How do medical plastics contribute to the field of neurology?

- Medical plastics play a crucial role in the field of neurology by providing innovative solutions for various applications. They are used to manufacture medical devices such as neurostimulation electrodes, brain implants, and catheters, which aid in diagnosing and treating neurological conditions. These plastics offer biocompatibility, flexibility, and durability, ensuring safe and efficient delivery of therapies and interventions. Additionally, medical plastics enable advanced imaging techniques like MRI and CT scans, enabling neurologists to obtain accurate and detailed images of the brain for diagnosis and treatment planning. Overall, medical plastics contribute significantly to the advancement of neurology by enhancing patient care and improving outcomes.

- Q: What are the regulations and standards for medical plastic?

- The regulations and standards for medical plastic vary by country and region. Generally, medical plastics must meet stringent requirements to ensure safety, efficacy, and compatibility with medical devices and pharmaceutical products. These regulations typically cover aspects such as biocompatibility, sterilization, chemical resistance, and mechanical properties. International standards, such as ISO 10993 for biocompatibility testing, ISO 13485 for medical devices quality management, and US FDA regulations, often serve as benchmarks for medical plastic manufacturers. Compliance with these standards is crucial to ensure the reliability and suitability of medical plastics for use in healthcare settings.

- Q: How is medical plastic recycled or disposed of?

- Medical plastic is typically recycled through specialized recycling programs that are equipped to handle the unique challenges associated with medical waste. These programs ensure that the plastic is properly sorted, cleaned, and processed to be transformed into new products. In cases where recycling is not possible, medical plastic may be disposed of through regulated methods, such as incineration or landfilling, to minimize environmental impact and ensure compliance with waste management regulations.

- Q: How do medical plastics contribute to the safety of healthcare workers?

- Medical plastics contribute to the safety of healthcare workers by providing a wide range of benefits. They are used to manufacture various medical equipment and devices, such as gloves, masks, syringes, and other protective gear. These plastics are designed to be durable, lightweight, and resistant to chemicals and bacteria, minimizing the risk of contamination and infection transmission. Additionally, medical plastics are often disposable, reducing the chances of cross-contamination between patients. Their use also enables healthcare workers to have better control over infection prevention measures and enhances their overall safety and well-being.

- Q: How is medical plastic used in neurosurgical applications?

- Medical plastic is used in neurosurgical applications in various ways. It is commonly used to manufacture implants and devices such as cranial plates, shunts, and tubing, which are used in procedures like craniotomy, shunt placement, and intracranial pressure monitoring. These plastics are biocompatible, meaning they do not cause adverse reactions in the body, and they can be easily sterilized. Additionally, medical plastics can be molded to specific shapes and sizes, allowing for customized solutions in neurosurgery.

- Q: How do I erase labels affixed to glass or plastic?

- Acetone, ditto. Less and thoroughly, and best of all, it removes the residual gum very quickly and easily. It is better than alcohol.

Send your message to us

Dental floss with flavor of land animal shape suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches