PET Bottle Preform Mould Supply 48 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

.Mould structure

Advanced structure is designed to improve rate of finished products;Two-step double taper locating technology;The each cavity is self locked independently with the core.The off-center adjustment system make the perform thickness error less than 0.05mm.Bottleneck is adopted International Screw thread standard, No cutting of gate to reduce the labor intensity

. Material of steel

Cavity and core use stainless steel 2316 with fine polishing,high hardness to get mold's high precision and good quality. mechanical treatment cavity and core to prolong service life,nitrogen treatment with neck screw.with fitly operation,guarantee Long using life over 2 million shots of injection cycle

.About gate system

Pin-valve gate,pneumatic drive the nozzle pin simultaneous high speed open and close action. which can effectively control the injection hole open and close actions on each cavity. reliable seal function, smooth moving, low thermal expansion rate ,long using life and also saves electric energy.

.About hot runner

The hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production ,cavity with lower injection pressure to reduce wear and tear of mould parts.we use the double heating system,it has separate temperature control mode ,the heat bar are used to heat the mould mainfold plate,small heaters supply the heating temperature for cavity nozzle continuously.

.Cooling system

Each parts including core ,cavity and valve gate has independently cooling system.

.special satisfied servive

Each mould undergoes strict mould test before delivery.we can provide an experienced team for installation and test as per client's request Standard inter-changeable mould components

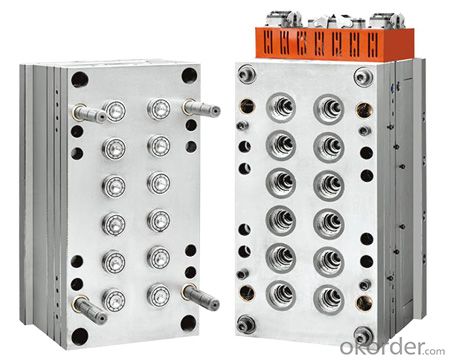

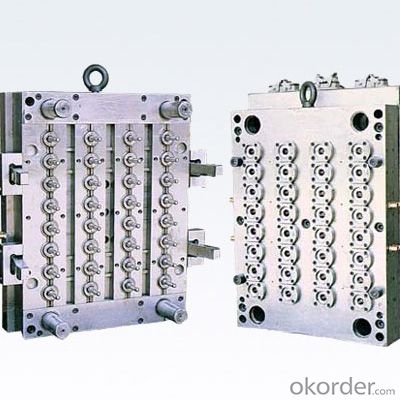

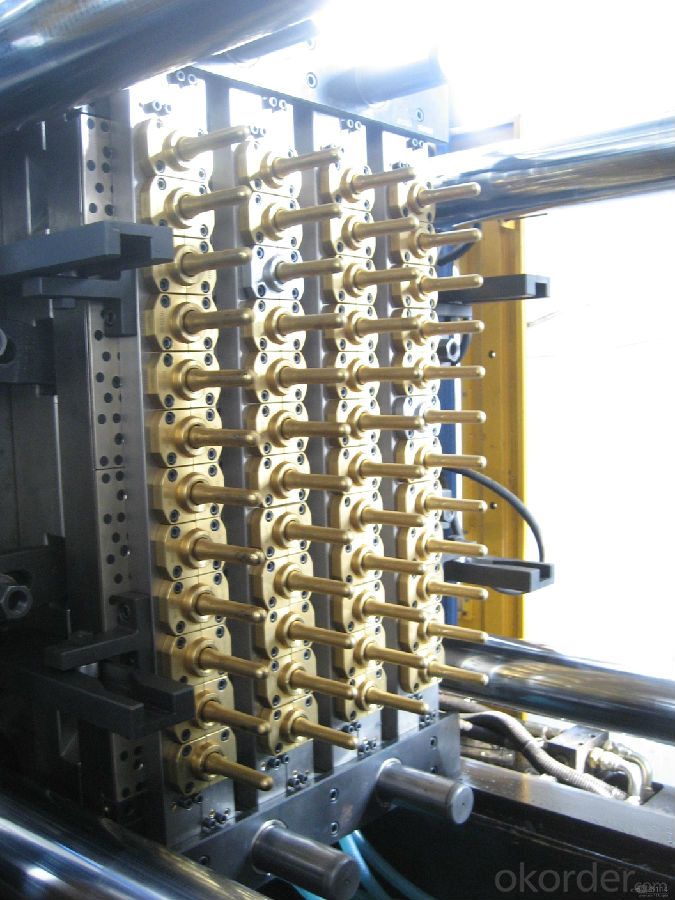

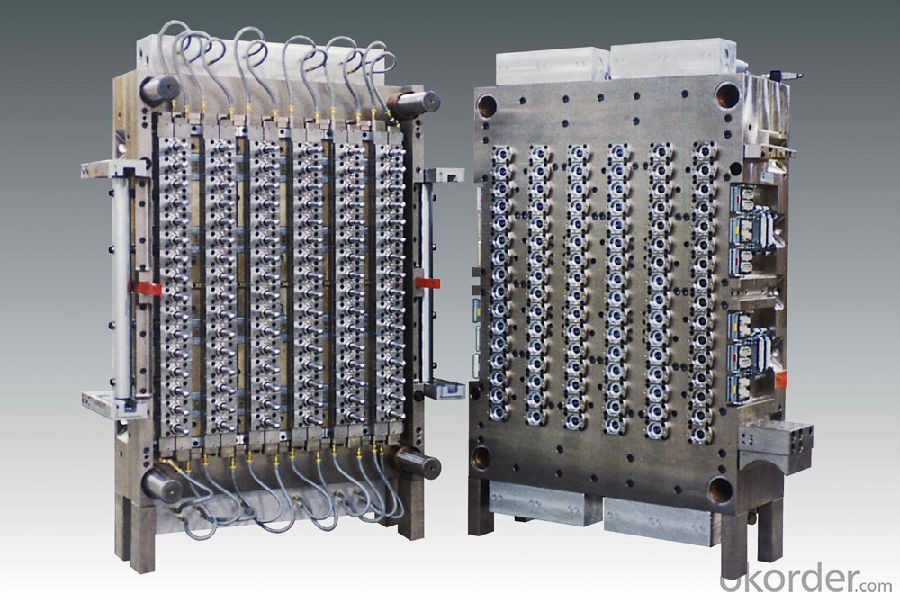

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

The company can provide full no-man bottle preform product line, which includes injection machine, mould robotic arm and moulds.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: How many kinds of equipment can be used to open the mould?

- The molds have a lot of equipment Most basic: lathe, milling, grinding machine, line cutting, drilling machine These are the most basic. And, of course, you need to press the bed for the test

- Q: What effect is the flange of the die

- Flanges are concentric with the jw, flanged, and the nozzle of the injection-molding machine, the flanged design corresponds to the size of the machine. You've seen the big hole in the injection molding machine. That's a match for the flange

- Q: How to choose the injection molding machine when the mould design

- All parameters affecting the molding machine should be taken into consideration: the size of the mould, the amount of glue, the locking force, and the driving distance. Today's injection molding machine is mature. All other parameters can meet the requirements as long as the mold can be molded. All the usual first consideration is to select the injection molding machine according to the shape of the mould. If the mold is special in some way, other parameters are given. For example, if the mold is particularly high, consider whether it is sufficient to open the module. Especially if it's flat, consider whether the lock force is sufficient

- Q: Why does the mold exhaust, so where does the gas come from

- There are several main sources of the gas in injection molding mold: the air in the cavity and the pouring system; The water vapor produced by the evaporation of water from the plastic material. Gases produced by plastic decomposition at high temperature; Gases produced by certain additives in plastics or chemical reactions, such as thermosetting plastics, are often produced by chemical reactions.

- Q: Is the digital control the same as the mold? If not, what's the difference?

- Han of course is different numerical control is a method, the mold is a kind of thing

- Q: What does the mold and the flying model mean

- It's the match model. If you know what to do with the fitter, you will know that it is the place where the higher ground is polished and the uneven ground is polished. Fly mode to use to the red lead, similar to Indonesia, the two sides laminating will have red mark, where sealant plane if there is no stamp, just sign here has a problem, will need to be polished. And this process is called the flying model. You still need to see it on the ground.

- Q: What is the main meaning of die mold?

- Abstract, you see, a product is a whole piece of steel material contained in it, you want how reasonable and effective to separate steel material remove products nondestructive complete smoothly, and you can also repeat separation and recovery of thinking process and results of a recognised are called parting.

- Q: How is the die in the manufacturing industry

- Mold entry should be separate: If the period of use is over one year, the fixed assets shall be credited, and the depreciation shall be gradually recovered from the period of time. entries Borrowing: fixed assets -- molds Loan: bank deposit/inventory cash/accounts payable 2) use fixed number of year within a year, or easy to loss, recorded in the packing materials and low-value products, you can use the double fifth amortization method (recipients when cancel after verification 50% cost, scrap again when the cost of cancel after verification of the remaining 50%)

- Q: What is the difference between the mold and the numerical control? The difference is?

- The design process of the tool and the performance of the materials needed are designed CNC is mainly for nc machine tools, need programming digital controlled drawing mould, in short, the mould is used for molding tool, this tool has all parts, different mould made up of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance. The mold can be divided into metal mould and non-metallic mould according to the material that is formed. The metal mould is divided into: casting mould (non-ferrous metal casting, steel casting) and forging die etc. Non-metallic mold is also divided into: plastic mould and inorganic non-metallic mould. And according to the material of the mould itself, the mold can be divided into: sand mold, metal mould, vacuum mold, paraffin mold and so on. With the rapid development of polymer plastics, plastic mould is closely related to people's life. Plastic mould can be divided into: injection molding mold, extrusion molding mold, gas auxiliary molding mould and so on.

- Q: How can silicone and glass steel molds be glued together

- As for the durability aspect is equal, it is easier to lose the texture of the silicon rubber mould. So if wandering between the building Lord, I suggest you according to the requirement of the customer, if the quality of high precision requirements of the customer requirements, so you must use silicon mold, on the other hand can also try using glass fiber reinforced plastic mould making low-end products.

Send your message to us

PET Bottle Preform Mould Supply 48 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords