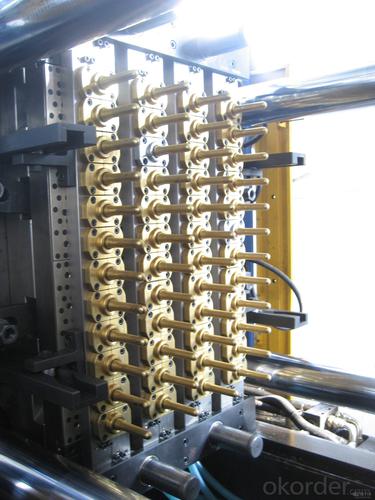

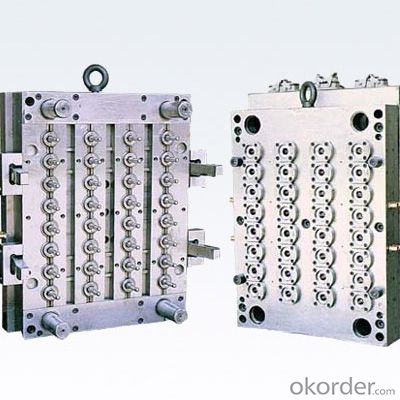

Needle-Valve Type Free Shear Preform PET Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Needle-Valve Type Free Shear Preform PET Moulding

| name | plastic pet preform mould |

| material | PP, PC, PS, PE, PU, PVC, ABS, PMMA ect. |

| Steel | 718H, P20, NAK80, 2316 |

| Steel hardness | HRC28-33 |

| Mould Standard | DME |

| Cavity | single/multi |

| Injection System | DIRECT GATE |

| Ejector System | EJECTOR PIN |

| Cycle Time | 30S |

| delivery time | 45DAYS |

| Mould life | 500,000SHOTS |

| Quality assurance | ISO9001 |

| Our Advantage | 1.High quality as custom |

| 2.Reasonable price | |

| 3.On time delivery | |

| 4.Good After-sale service | |

| 5.Strict quality control | |

| 6.All the mould are automotic | |

Our Services

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

Product Description

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

- Q: The characteristics of cold making die steel

- The hardness and abrasion resistance of cold steel mold is high Stamping die: Cr12MoV SKD11 DC53, etc

- Q: What is the difference between the electric casting mould and the CNC working mould

- Electroforming mould cavity is electricity casting processing, is to do a the same electrode and the product shape, with a thick layer of metal plating electroplating way, down to do mold cavity, general decorations in this process. CNC is also called processing center, which is the direction of computer control tool, which can be processed into very complex shapes, most of which are processed in this way

- Q: The function of die water board?

- Plastic mould is divided into two plate mold, three board mould, three board mould is two open mold, mold has a nozzle plate, nozzle plate is used to open mold for the first time the shuikou material pull out from water mouth, and then move back as the mould, due to the limit lever pull nozzle plate, injection molded parts and runner plate on the dynamic model of shuikou disconnect, complete the whole process of open mould.

- Q: What does the mold and the flying model mean

- It's the match model. If you know what to do with the fitter, you will know that it is the place where the higher ground is polished and the uneven ground is polished. Fly mode to use to the red lead, similar to Indonesia, the two sides laminating will have red mark, where sealant plane if there is no stamp, just sign here has a problem, will need to be polished. And this process is called the flying model. You still need to see it on the ground.

- Q: What is the difference between imported mold and domestic steel

- One, the biggest difference is the price of imported materials is high, commonly in domestic material more than double. Second, steelmaking technology perspective, foreign well-known steel material generally purity of molten steel is higher, P, S, and five element content is low, low gas content, is simply less impurity. From the forging point of view, the imported mould steel is generally good, the forging pressure is bigger than the big, simply it is the uniform and transparent of forging. Four terms, heat treatment, the overseas research and development efforts, compare the commonly used die steel are basically developed abroad, so the heat treatment craft is advanced, and the equipment is advanced.

- Q: How long is the life of die casting die?

- Aluminum: 120000 times Copper: 20000 times Magnesium: 200000 times Zinc: 500000 times Benchmark, the product structure added and reduced die life

- Q: The difference between wire cutting and mold making

- (4) test and test. Because of the characteristics of the mould and the experience of mould design, the mould must pass the test or the test pressure after assembly, and finally determine whether it is qualified. At the same time, there are some parts that need to be tested to be finalised. Therefore, there must be a certain testing period for the production schedule. (5) the machining of molds to mechanization, elaboration and automation. At present, the demand of product parts for mould accuracy is higher and higher, high accuracy, high life, high efficiency and more and more. The machining accuracy depends mainly on the precision of machine tool, the processing technology condition, the measuring method and the method. At present, precision molding grinding machine, CNC precision surface grinding machine, precision CNC wire-cut edm machine, precision continuous trajectory coordinates grinder and the use of three coordinates measuring machine is becoming more common, mould processing to the intensive development of high and new technology.

- Q: What is the manufacturing of mould materials

- Mold material is very wide, there are steel. Copper alloy. Aluminum alloy and so on metal materials, also have wood. Gypsum. Plastic etc. Nonmetal material, so make it industry is also widely, such as using a standard steel belongs to steel industry; The materials used in non-ferrous metals shall be in the casting industry; For example, the wooden model of casting is in the wood industry and so on.

- Q: Where is the mould industry in our country?

- Shanghai Shanghai has more than 1, 500 molds enterprises, with more than 70,000 employees and annual output of nearly 10 billion yuan, with an average annual growth rate of more than 20 percent. By 2010 the total output will be around 20 billion yuan. Imports from the current 290 million yuan based on compressed 30%, will increase 700 million yuan output value of industry, exports reached $130 million, and will increase 600 million yuan output value of industry. Shanghai mold industry will face six major industries and key industries, especially the information (IT) industry and automobile industry, vigorously develop the IT industry precision magnesium alloy die casting, precision injection mold; The auto industry covers molds, large parts die-casting molds and precision stamping parts. In 2010, 85 percent of the molds in the IT industry were manufactured and 90 percent of the auto molds were produced.

- Q: What mould steel can make injection mold?

- Usually the die frame is 45 #, the core is usually P20, P20H, 718,718 H (H is the hardness of the steel) an H value indicates that the hardness is increased by 0.2.

Send your message to us

Needle-Valve Type Free Shear Preform PET Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords