PET Preform Injection Moulding China OEM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Advantages of Multi-Cavities PP Preform Mould

Characteristics of the production line

First: PET material→dehumidify→load material→injection machine→ preforms

Second: PET Preforms →heat preform → stretch → blowing → bottles

Cap on in the injection molding machine is completely automated production, its production process is as follows::

PP material→load material→dry→heat material →injection→cooling molding →preforms→cap

Injection molding machine: Adopting Europe technology, hydraulic unit adopts proportional pressure and flow control, the pressure and the speed can be adjusted, stable movement curve and gentle shock, the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection molding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators’ safety.

Mould: Our mould producing center produces exact mould, adopts the high grade material to make. The perform mould uses the hot runner technology, inside uses the imported steel, the surface’s brightness is very high and the service time is very long.

1.The design of equipment is logical, easily operation.

2.The automatic level is very high, the wage is very little.

3.Using famous imported hydraulic, electrical, sealing parts, the trouble is low.

4.No matter what the product’s outside or inside, they can get the best guarantee, the good products rate can be above 99%

2. Main Features of Multi-Cavities PP Preform Mould

Mouse mould design is a brain demanding work which has no copy action.

When designing a mouse mould the method of modification should be taken into consideration and should have enough space for modification.

The devices of the mouse mould should meet the standard of anti-grating and long-life shots.

The manufacturing skill and time are different with the hardness and stretchiness of the material.

Because of its precision, most of work has to be done by manual work.

Mould of high quality should be qualified with good surface manufacturing and precision

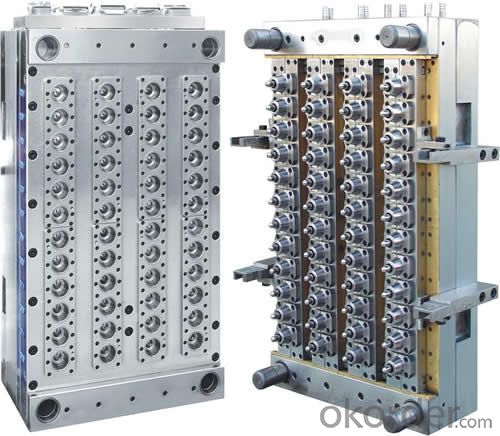

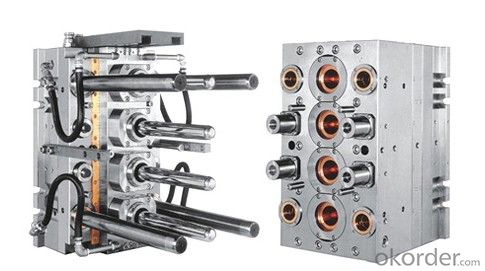

3. Images of Multi-Cavities PP Preform Mould

4. Instruction of Multi-Cavities PP Preform Mould

We complete mould making line, from the mould's design, processing, assemblage, test to perfect mould. The mould designed by AutoCAD system, PRO-Engineer system, Solidworks system etc.

For the mould processing, we use precision machines and CNC machine.

For the mould assemblage, we have experienced workers who has more assemblage experience. With carefully work attitude and rich experience, make our mould quality better and better.

For the mould test, our company also make all kinds types of injection molding machine, this is our excellent, as other mould company not have this advantage for good testing.

For PET preform mould, there are 8 cavities, 16cavities, 24cavities, 32 cavities 48 cavitied and 72cavitied for choice.

PET material because of its exceptional performance, are generally used two-step molding process, by the preform injection molding machine to produce a 24-hour After cooling, the internal molecular structure of their re-arranged in an orderly manner, and blowing for the next step to create good conditions, so that more excellent blowing performance products. Such as the famous Coca-Cola Company is currently using this technology.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: What is the top of the die?

- The top block in the mould is a part of the mold and the punching die. The main function is to remove the material and help the molded parts get out of the mold.

- Q: Is the slanting and shoveling chicken in the mold the same thing, shoveling the chicken? Where is it used?

- I have never heard of what it is called The main function of shoveling a chicken, which is also called a slider lock block, is to compress the slider There is another type of spatula in front of the former mold which is the top of the chicken It's double insurance on the back

- Q: What kind of mold do you have?

- Die mold Die casting, hot chamber die casting machine with vertical cold chamber die casting, die casting machine with I type cold chamber die casting, die casting machine with full vertical die casting, die casting machine with non-ferrous metals (zinc, aluminum, copper, magnesium alloy die-casting, black metal die-casting mould Non-ferrous metal and black metal pressure casting process 4 Forging die Die forging and large press, forging die, forging die, roll forging die, etc. All kinds of fastener cold heading die, extrusion die, drawing die, liquid forging die etc Metal parts are formed and are pressed and compressed

- Q: What is die parting face?

- This should be plastic (especially injection mould term. Generally speaking, the mould has two major components: dynamic model and fixed die (or male mold cavities and cores). Parting surface is closed and state can contact between the two parts.

- Q: How long is the life of die casting die?

- Aluminum: 120000 times Copper: 20000 times Magnesium: 200000 times Zinc: 500000 times Benchmark, the product structure added and reduced die life

- Q: How many products can a mold make?

- Simple molds are less, a good order of hundreds of millions of molds can be done, but some parts need to be fixed regularly

- Q: Which of the dies is movable

- Mold is fixed before, so also called in front of the fixed mold, mold finish after open mold - out - clamping and a series of movements, after mold also called dynamic model,

- Q: How do you handle the die holder

- Clip, clip wire, usually refers to Parting surface (Parting line or the Parting line), including the slider, inserts, lifter and so on between the two in the products with line. If the surface requirements are high, they are generally combined to discharge and polish.

- Q: Because many of the molds in our factory have batch sewing, who can tell me how to fix the batch seam. Because I don't understand, but I'm going to learn, so I want to know in advance, thank you very much!

- If solve the above problem is mould itself reason, please use red lead to mold fitting well, the original poster check mold in touch wear, wear a location, see if cooperate in place.

- Q: How do you play the continuous stretch mold

- It is almost impossible to form a single shape. The concrete steps are not clear, but the rough step is to pull the outside circle first, then take the small circle and take shape.

Send your message to us

PET Preform Injection Moulding China OEM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords