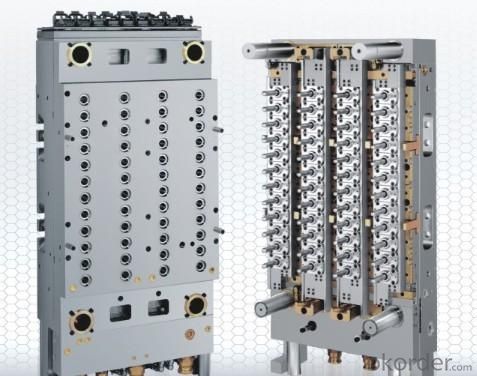

Pet Mould Making Plastic Injection Pet Preform Mould amd Pet Blow Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pet Mould Making Plastic Injection Pet Preform Mould amd Pet Blow Moulding

Plastic injection Mould standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM STANDARD | |

| 2 | Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

| 3 | Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| 4 | Hardness of steel | 46~56HRC |

| 5 | Material for Slider ,Lifter and all sub insert use | 1.2767 HRC |

| 6 | Cavity | Single-cavity ,Multi-cavity |

| 7 | A surface request | EDM & High Polish |

| 8 | Gate | Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

| 9 | Maximum mould size | 1500*1500 mm |

| 10 | Mould life time | 500000~+1,000,000 shots |

| 11 | Quality | ISO9001-2008 certification |

| 12 | Product material | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

| 13 | Lead time | 4~6 Weeks |

| 14 | Package | Wooden/Plywood case for tool ,PE bags add export carton for parts |

| 15 | Payment terms | T/T |

| 16 | Trade terms | FOB XIAMEN |

| 17 | Export country | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

| 18 | Value-added service | Polish,texture,painting,screen printing,turnkey project |

| 19 | As a professional Plastic Injection mould ,Die casting Mould & Moulding manufacturer, our range products are covered from Automobile,Electronic,Industrial,Household,Medical,Sport,Office etc | |

| 20 | Clients project's 3D drawings or samples are highly appreciated | |

Our Services

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

Product Description

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

- Q: What does a factory do?

- The things we use in our lives, washbasins, computers, plastic boxes, cell phones and so on

- Q: What is the role of the grooves in the guide column

- We usually call it "tank." You can touch the butter in it! At the time of the mould, touch the butter, lubricate and extend the life of the guide column.

- Q: The processing method of the mold cavity processing center

- The common processing procedure of the cavity: (milling) around and on both sides, the thickness remains 0.4 minus 0.6rnrn. Two sides of the face and two sides of adjacent side, the surface roughness Ra is 0.8 mu m. The shape of the fitter and the position line of the screw hole. The pattern required the milling out of the cavity, the unilateral remaining balance of 0.3 one-half mm, The machine drill screw holes, thread and so on. 6. Heat treatment. The electrode is used in a rough machining cavity. The worker finishes the polishing. The design calls for chrome plating, etc. The equipment was repaired and inspected.

- Q: I have a glass fiber reinforced plastic mould, I want to do with resin imitation jade, don't know way it doesn't, and resin products must use silicone mold can, if use FRP mould can, what kind of release agent is good?

- I think my answer is that glass steel can be made. Imitation jade is very similar. 2 resin products are mostly made of resin mold, most of the glass fiber reinforced plastic abrasive and glass fiber reinforced plastic products are made by resin raw materials, such as trash. Stool and other civilian products and their trash abrasive abrasive tool stool mould is made of resin. But some products without rules By other materials to replace Such as silica gel, gypsum, etc Some glass fiber reinforced plastic relief also do grinding tool with mud. Their use and their advantages are now in full play. If you use a glass and steel mold, I suggest you use the yellow wax and you can buy the imported towing water.

- Q: What is the number of holes in the mold?

- That's the number of modules It's usually professional to say that the mold is a few lumens An eight cavity means that the mold has eight holes that are capable of eight products

- Q: What do you mean by plastic mold injection molding? What's the use?

- Bao subsection to the holding pressure and holding time, at the time of injection molding, about 1-2 seconds can not the mould cavity while curing fill, and then the molten plastic cooling in the mold, the volume will narrow. So after injection molding for 1 to 2 seconds, you set the pressure time and pressure pressure to continue to press the plastic into the mold, and time is the time

- Q: Basic knowledge of die fitter

- Introduction to the bench The fitter is the method of machining by hand. 2. The characteristics of the bench has three major advantages, flexible processing, processing complicated shape and high precision parts, small investment), two big weaknesses (low production efficiency and the intensity of labor and processing quality is not stable). (1) working flexibly in a machine that is not suitable for machine processing, especially in the maintenance of mechanical equipment, the work of the fitter is satisfactory. (2) for processing complicated shape and high precision parts skilled bench can work out better than modern machine tool parts processing precision and the bright and clean, can work out the shape of even modern machine tool will not be able to process the complex parts, such as high precision measuring tool, mould, beginning complex, etc. (3) the equipment and equipment used for the processing of small fitter are cheap and convenient to carry. The production efficiency is low, the labor intensity is large

- Q: How many products can a mold make?

- Associated with the material of mould and casting method, had better use a scale of 0-8000 pieces of aluminum mould (ordinary sand casting), 0-13000 pieces (molding machine), plastic mold is bad to use, steel is the most strong, but not suitable for manual operation.

- Q: Where is the mould industry in our country?

- jiangsu Jiangsu suzhou currently has more than 1000 kinds of mould factories, more than 1000 die processing points, with annual sales of about 5 billion ~ 6 billion yuan, mould industry is one of the new industries in the city. Japan, South Korea, Singapore, Germany, the Netherlands, the United States and our country Taiwan, the Hong Kong area sole proprietorship, the joint venture enterprise, the private mould enterprise is quite a few; Suzhou lampe casting, molding, and other far lighter company mainly produces automotive engine and wheel and other components die-casting die and mold, kunshan large formwork, kunshan precision mold standard parts, such as pieces of kunshan huaxing mold oriented enterprise specializing in the production of various kinds of large formwork, mould guide pieces, die springs and other standard parts.

- Q: Do machine parts need to be moulds?

- It is necessary to make the machining parts in large quantities, which are complicated in shape and need to be moulded.

Send your message to us

Pet Mould Making Plastic Injection Pet Preform Mould amd Pet Blow Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords