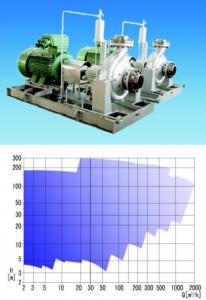

Petrochemical Process Pump ZA Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description

Type ZA Petro chemical process pumps, according to API 610(8th edition), for pumping clean or slightly polluted. cold or hot, chemically neutral or aggressive liquids.

Application ranges

In refineries, petrochemical industry, coal processing and low temperature engineering.

In chemical industry, fibre and general processing industries, particularly in paper and pulp industries, sugar industry.

In water industry, particularly seawater desalination plants, power stations.

In heating and air-conditioning, environmental protection engineering, ship and offshore industries.

Performance range

Sizes DN:25-400mm

Capacities(Q)3-2600m3/h

Head(H)4-250m

Operating Pressures(P)2.5MPa

Operating temperatures (T):-40℃~+300℃-40℃~+450℃(Center support)

Instruction of pump type

For example:ZA80-160A

ZA—single stage Chemical Process Pumps

80——pump outlet diameter

160——impeller diameter

A—— outer diameter of impeller is changed the first, second time.

Construction

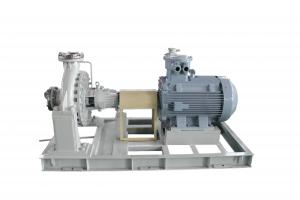

Single-stage, horizontal, radial split volute casing pumps with feet below and single-entry radial impeller, end suction branch, radial upwards discharge branch.

Depending on operating conditions hydraulic balance provided by front or rear wear rings and balance holes. Casing cover with cooling or heating connections, shaft sealing by packing or mechanical seals of any design(single or double working), connections for cooling, flushing or sealing liquid

Standardized pipe work according to API plans.

The rotation of the pump rotor is clockwise looking from the motor to pump.

Pumping medium

Organic acid and inorganic acid such as sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, which at various temperature and concentration.

Various salt solution.

Various liquid petroleum chemical products, organic compound as well as raw materials with corrosive and the products.

At present, anti corrosive materials for pumps provided by our plant can meet all the requirements of the medium mentioned above. Please provide the detail service conditions for pump to us, when you order.

- Q: can't get the pulleys to line up I know I have a mid 70's 400 and the water pump is later than 1969 but I can't find a pulley that works every one is about a half inch off I bought a aftermarket set of underdrive pulley's from march performance and still the same problem the water pump is a half inch off there was no long or short water pump right they are all the same lenght right??? The only difference I know of is that pre 1968 the pumps have a 8 bolt design and after they have a 11 bolt design is that right???

- did you happen to loose the aluminum spacer between the water pump output shaft, and the fan pulley?

- Q: How much would it be in labor and parts to change a water pump and on a 2000 Dodge Durango 5.9 4 wd with 109k.miles? Should I change the timing chain? If you can please give me a estimated Thank You!I getting tired of old Vechiles LOL

- The cheapo water pump from oreillys is $46, the higher end one is around $70. As far as labor, Mitchell OnDemand calls for 2 hours flag rate time to change it out. You'll probably be looking at at least 1 gallon of antifreeze as well for what will be lost changing it out, and I would recommend changing the thermostat when you change the water pump. The 5.9 uses a timing chain, which I wouldnt recommend replacing, seeing as the vehicle has that low of miles on it. I'm not sure how much labor costs in your area, but the shop I work at charges $75 per flag rate hour. So if we were to do it, taxes and everything it would be right around $250. If you live in a big city, you'll probably be expecting to pay around $100 a hour for labor at a reputable shop. Good luck and hope this helps.

- Q: I just bought a house and we have well water. When I went out to change the filter on the pump I noticed a valve leaking...I went to check on it and noticed it had two settings if you will. one says System and the other says by pass if I move the lever to system the leak stops, if I move it back to bypass the leak continues...question is which one should I have it set on and what is the purpose?

- Okay, Adam, we also have a well and just put in a new one. The setting that says System means that the water is running through the filter. The setting that says by pass means that the water is NOT running through the filter. You will have water either way in your house (or you should). It is just either, it is running through the filter, or it is not. I hope I have helped. gram

- Q: When we turn our water on in the house it will run for a while and then shut off.. It has been coming back on after 5 0r 6 mins.it used to do this about once a week but now it does it every day we don't mess with any breakers because they don't get triped . We are on well and this well is about 7 yrs old anyone have an idea what could be the problem .. If any more info is needed I can reply..

- ANY extra info is a plus. Well size and construction, depth, water level, production test results, and pumping apparatus, all help in troubleshooting problems. The two most likely things I can think of that would make your water pressure act the way it does are as follows. My first guess is that your pump is capable of pumping more water than the well will produce, thus drawing the level of water in the well down to a point where the pump catches some air and quits pumping. The pump continues to turn and when enough water comes into the well to cover the pump, it's starts to pump water again. Second guess is that you have a thermal overload tripping and when enough time goes by, it resets and turns the pump on again. Overloads often trip when you have a low voltage situation at the motor. You can get low voltage form bad connections @ splices or the contacts of the pressure switch. Most well water systems go a long time between maintenence calls, especially at first when EVERYTHING is new. My advise would be to call the contractor that drilled the well and installed the pumping equipment. Hopefully they are one and the same. The contractor knows the original conditions and all equipment used, even the stuff you can't see. Because the system is relatively new, the original contractor MAY be inclined to cut you a deal on repairs. We don't know how long this problem has existed, but perhaps the system really wasn't up to par right from the start. Good luck. When you talk to the contractor, try not to sound to accusatory. He may have done his best with the geologic and economic set of conditions he was given. Nobody can make gold out of lead.

- Q: What are the parameters of the pump price?

- The first point: brand, manufacturers are generally different, the price difference is relatively large, the brand effect and quality of this.The second point: motor model and matching pump model, the general power is greater, the higher the price.The third point: special requirements, such as: to achieve a special lift, or special flow, special materials, special maintenance period, the rate of special accidents. The price is higher than the usual model.Basically, these are the pumps that determine the price of the pump. In fact, the same manufacturer, the power difference is not too large, there is no special requirements, the price is basically the same, the reason manufacturers do not the same price, is a marketing strategy, in fact, the cost is the same.

- Q: Home water well is artesian, to holding tank. I am needing to replace my pump yearly. Inside of the pump is rusted, this causing a real loud whining sound before failure. Pump motor isn't failing, the inside of the pump ends up freezing loosing the ability to spin.Any suggestions as to why?

- that's a vague description of the pump. theres several types of pumps too. you need to either shield the pump, or move it to a different location, so its nots moist and damp all the time. drop a sand point down to the well, seal the well from the pump , or buy a different type. call a well service and ask them your options. good luck man! gee, that must get expensive.

- Q: What are the commonly used tools for repairing water pumps? Mainly for civilian 220V submersible pumps, self-priming pumps. How much is the spare parts ready for use?

- Because had done a mechanic, and relates to a pump, not including motor repair, commonly used tools: pliers, pliers, adjustable wrench, wrench, screwdriver, bench drill, multimeter, electric iron, Lamar, hammer, ruler, chisel. Commonly used parts: bearings, impellers, screws, terminals, lubricants and so on.

- Q: Last week I took my 1999 Plymouth Breeze to auto zone to get my engine light checked. It came back saying electrical and that my water pump is leaking? So what does that mean, do i have to replace the pump?

- An engine scan will not tell you your water pump is leaking. Take it some place that knows what they are doing.

- Q: My water pump is starting to leak. The shops are quoting $250- $300 to replace but I can buy a water pump at the auto parts store and install myself for less than $100 but I don't know what all is involved with this repair or if I should try (my only experience with car repair up to now is recently replacing the alternator). If anyone has done this please let me know what you think. thanks

- you can make it even easier by purchasing a hayne's manual for your car when you buy the water pump. you will need it anyway so you can have the proper torque specs and sequence when reinstalling the new water pump. so if you don't have a torque wrench you will need to rent one. the first step of course will be to drain your cooling system. then use masking tape and a sharpie to number any connectors or hoses you have to remove to access the water pump. once the old one is off make sure to clean every trace of gasket material from the mating flange. then when you are ready to reinstall put a thin coat (use you fingers to spread)of rtv silicone to each side of the new gasket this will help hold in place. then here's where you will need the book insert the bolts and tighten them in sequence shown to the proper torque unless you want to chance cracking the new pump housing. on a car this old if it has not already been done now would be a good time to replace hoses (esp. if they are soft) and your thermostat since you've already got the cooling system drained. once everything is reassembled start the engine and begin pouring in the new coolant, if there are any bleed screws open these it's very important to get all the air out of the system if there are no bleed screws you can leave the cap off the radiator or expansion tank (you'll need to anyway) since one you think its filled when the thermostat opens its all gonna drain down and you'll have to top it off again. here is a good time to pay attention as it approaches normal operating temp be ready to start pouring as soon as the level starts to drop that will help keep more air from getting in. any questions feel free to e-mail me

- Q: I have a bad water pump on my golf gti.Engine is 2.0L. I just would like to know how hard is it to do it myself. And also is there some special tools that I need.How much time usually takes to get this done? Thank you

- This Site Might Help You. RE: 96 vw golf gti water pump? I have a bad water pump on my golf gti.Engine is 2.0L. I just would like to know how hard is it to do it myself. And also is there some special tools that I need.How much time usually takes to get this done? Thank you

Send your message to us

Petrochemical Process Pump ZA Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords