ZA Petrochemical Process Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

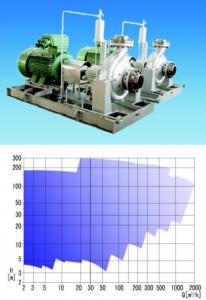

<1>Technical data:

a) Flow Q≤2400m3/h

b) Head H≤300m

c) Operation pressure P≤2.5MPa

d) Medium temperature:T -80-+450

<2>Features:

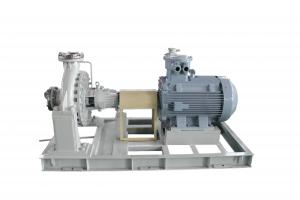

a) Single-stage horizontal radial cut-opened spiral casing pump;

b) The impeller is a single-suction radial one

c) Axial suck-in and radial drain

d) Axle seal at ex-works uses a single or dual endface mechanical seal, either a packing seal

e) Anle seal fitted cooling

<3>Application:

a) Oil refinery, petrochemical industry, coal process Industry and sub-zero engineering;

b) Chemical industry, paper making, paper pulp, sugar refinery and common process engineering;

c) Water works, sea water desalt plant;

d) Warming and air-conditioning system;

e) Power plant;

f) Environmental protection project;

g) Ship and maritime industry and so on.

<4>Structure characteristic:

This pump is single-stage horizontal radial cut-opened spiral casing pump. The pump casing is foot supported and the impeller is a single-suction radial one, axial suck-in and radial drain- out. Both front and rear oral rings and balancing hole are used to balance the axial force upon the conditions of use. The stan-

dard designed axle seal at ex-works uses a single or dual end face mechanical seal, either a packing seal, and is fitted cooling,rinsing or seal liquid system.(Please make a note in the contract ,in case of a special requirement with the axle seal).The standard pipeline is designed per API. The rated pressure

classes of the flanges on both suck-in and drain-out pipelines

<5>Medium:

The vitriol, nitric acid, hydrochloric acid, phosphoric acid etc. inorganic and organic acids of various temperatures andconcentrations; the sodium hydroxide, sodium carbonate etc. alkaline solutions of various temperatures and concentrati ons; various salt solutions.Various liquid petrochemical products, organic chemical compounds and other corrosive raw materials and products.The corrosion-proof materials available at present in this C o.can meet with the demands of the above media. Please provide the detailed information about the medium to be transported at order.

- Q: I do pump sales ~ only to enter the line soon ~ often asked how many levels of motor? I can't recognize myself! So ask for advice here

- You can also use the motor speed divided by 50, equal to the motor series.

- Q: Fire pump control cabinet installation distance, ground height should be how much?

- The ground height shall be determined according to the height of the connecting line at the bottom of the control cabinet and the water pump, usually 15~20CM.

- Q: Is the pump head related to the water level of the entrance and outlet? If the water level of the inlet and outlet is on the same level, but higher than the height of the pump, does the pump lift need to be coupled with this height difference?

- What's the relationship?! When the inlet level is low, the head is slightly higher than the liquid level!

- Q: i have a jetta and would like to know how difficult it would be to do. I know its a german car this is why i ask. thanks

- The water pump is driven by the timing belt on that engine. You don't have to take the alternator, power steering pump, or the a/c compressor off, but you do have to make sure it is timed right. Not too hard to do, just make sure the marks line up. Good luck!

- Q: Ok i was wondering which is the from hose off of the motor the bottom or top since i thinl my heater core hose are reversed and i only get nuke warm air and not hot and yes ive got a brand new heater core, new anti freese, new thermostat and gaskets and all hoses are clear and not rust in the system

- I think the info you are looking for is which heater hose supplies the heater core and which hose returns the water to the system. The heater core has two connections, the bottom is usually water in, the top water out. Generally the hose from the top of the engine supplies the heater core and the hose going to the water pump is returning back to the system. Having cleared that up, it doesn't really matter, even if the hoses are reversed, coolant will flow through the heater core regardless, unless there is a control built into one of the heater hoses that actually cuts off the flow of coolant to the heater core. Some trucks have them some don't. If yours does, check that it is working properly or remove it altogether. Now let's examine the possible source of your problem. I would look at either the heater control in the cab or the heater box itself. In the early 70's GM started using pneumatics, and vacuum operated components for their environmental controls. Vacuum operated doors opened and closed to allow airflow to different parts of the system, A/C, defroster, vents, heat, etc. A vacuum leak, a kinked hose, a bad control will cause the doors to stay closed, giving the illusion that there is no heat. By the same token, the wrong door stuck open could allow excessive outside air to mix with the heated air effectively cooling it off, but that is not likely. Check the main control in the cab, and the vacuum actuators and hoses. If by some chance yours still has the steel cables, make sure they are well lubricated, connected, and functioning.

- Q: Was I supposed to lube the water pump or what. I really don't know what it could be making the noise now. But it goes away after about 5-25 seconds of running, what could it be?

- Check closely, you may find that the pulleys are not lined up completely. Have you had the power steering pump replace? Very common to have the pulley not pressed on completely, causing the ribbed belt to not ride properly on the pulley, causing squeaks.

- Q: I'm using an old Mitsubishi Lancer. Recently I changed my water pump it was leaking.To me it looked like a piece of metal, with a small fan thing (not motorized) How can it fail? There is no mechanics to it, just like a pipe with a fan (or turbine)I also messed with my radiator, I unhooked the main hose to clean out the coolant, since the plug was jammed. Could this have contributed to the failing of my water pump?

- The water pump has a gasket inside to stop coolant from leaking out. When the gasket fails, coolant comes out of what is called a weep hole. If you don't replace the water pump, the bearing gets saturated with coolant and fails. When the bearing fails, the water pump pulley ceases and the belt fails. I have seen this too many times.

- Q: I just replaced my water pump.fixed.. A week later I've been noticing he might of over filled it because.were the coolant goes.steam comes.out.the little.while plus water.. And.before.I.started my.car I noticed.it was all empty now and my.engine sounds like a mini diesel when it runs.. What's the deal? And I.already filled it up with coolant again

- Anytime you replace your water pump. You should replace the thermostat and gasket. Also check the upper and lower radiator hoses to see if either one of them are collapsed.It wouldn't hurt to replace the radiator cap.

- Q: 4--6 inch deep well pump head? How much per hour out of water?.

- Deep well pump head is based on how much the impeller, impeller 200QJ section is 11 meters lift, 250QJ is about 17 meters, 300 meters high lift, 4 inch flow in 80 to 100 tons per hour, 6 inch flow in 150 to 200 tons per hour

- Q: Why does the water pump leak?

- The sealing ring is invalid

Send your message to us

ZA Petrochemical Process Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords