Petrochemical Process Pump with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

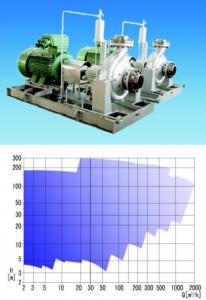

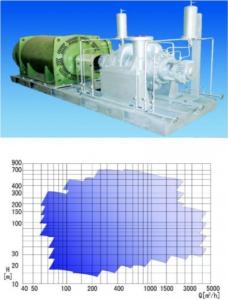

Petrochemical Process Pump

Description of Petrochemical Process Pump

ASP5030, ASP5040 series are centrifugal chemical process pumps, which are developed based on the advanced pump manufacturing technologies domestic and abroad. They are designed to be horizontal single stage single suction radial split series pumps in line with the specifications in API610(the eighth version)and API682

They can be applied for the power of 50HZ and also 60HZ.

The pump follows the standard of ISO, API, GB, ASTM and JIS.

Different materials for wetted parts is available according to the liquid characteristic.

Application Area of Petrochemical Process Pump

Chemical industry, paper-making, pulp industry, sugar industry and the common process industry

Water supply plant, seawater desalination plant

Heating&air conditioning system

Power plant

Environmental protection project

Shipping&marine industry, etc.

Performance Range

DN: 25~400mm

Capacity(Q): 2500M3/h

Head(H): 250m

Working temperature: -80oC~450oC

Working pressure: (P): ASP5030up to 2.5MPa ASP5040up to 5.0MPa

Structural Characteristics of Petrochemical Process Pump

The balancing holes with wear-resistant rings are applied for the impeller to balance the axial force.

There are cooling or heating pipe joints for the packing box.

The packing seal, single mechanical seal or double mechanical seal can all be applied for the shaft seal. There is also auxiliary cooling, flushing or sealing liquid systems.

Taper-threads are applied for flushing and cooling joints for the casing, pump cover, intermediate bracket and sealing gland, which enhances its sealing ability and reliability for pipings.

The pumps with their outlet diameter more than 80mm. Their casings are designed to be of double volute to balance its radial force, which guarantees the bearing service time and the bending capability for the shaft at the shaft seal.

Closed impellers are applied for both ASP5030 and ASP5040 series pumps, which are characterized by their high adaptability, high efficiency and low NPSH etc.

Open impeller is applied to transmit the gas and liquid two-phase and the liquids with great solid particles concentration(max. Particles diameter 8mm, or 10% volume concentration).

Bearing structure and cooling: Bearing bracket is supported with a set of radial ball bearing and two sets of thrust ball bearings mounted in back-to-back. Bearings are lubed with oil rings or oil mist when specified. Bearing outside surface is furnished with cooling fin, which can be air cooling (T<120oC), fan cooling(T=120oC~260oC)and water cooling(T=260º C~450º C).

FAQ

Q: Can your pumps mount Eff.1 motors

A: Currently, only on request though this will shortly be a CNBM standard.

Q: Are your pumps protected against dry running?

A: No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

Q: Do you have self-priming pumps?

A: Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

- Q: The single-phase water pump in the house is out of order. After opening the power supply, the motor can not start by itself. It is necessary to turn the shaft clockwise by hand. Then, what is the problem? How can I solve it? Thank you

- Is your starting capacitor pump is broken. Because you pump it is a single asynchronous motor..... Single-phase asynchronous motor by capacitive phase shifting function, the single-phase alternating current isolated from another 90 degree phase alternating current. The two alternating current into two groups or four groups of motor winding, forming a rotating magnetic field inside the motor rotating magnetic field induced current in the rotor, the induced current magnetic field and rotating magnetic field in the opposite direction, by rotating magnetic field push pull into the rotating state, because the rotor must be cutting magnetic lines to produce induction current, so the rotor speed must be lower than the rotating magnetic induction motor speed, so thatSo if the starting capacitor is broken, then your pump will start difficult,

- Q: Difference between primary hot water pump and two hot water pump

- A hot water pump is a water pump circulating between the boiler and the heat exchanger, and the two hot water pump is a circulating water pump between the heat exchanger and the user. That is, there is no relationship between a water pump and heating users.

- Q: I think my water pump is leaking and I want to replace it, but I can't figure out how to get the pulleys off. There is a large nut on the shaft that the pulleys are on, and I can't figure out how to remove it, or if the nut is attached to the shaft, and the entire shaft is supposed to come out, or how it's set up. Please help. Pictures would be great if possible. Thanks!

- With the belts ON - take a big wrench ( 12 crescent or ) and place it on the large nut holding the fan on. Carefully smack it counter clockwise, (lefty loosey) until it comes loose, The threads for it are on the pulley. remove the 4 or 5 bolts holding the pulley, ( a vice grip on the large threads will hold the pulley to help remove the pulley bolts. Remove the water pump. Clean the gasket mating area GOOD - when you think you have it clean - clean it again - You do NOT want to find it leaking when you are finished. Some prefer RTV silicone sealant -- I prefer permatex #2 non-hardening. Tighten all the bolts only slightly before the two final torque's are completed - do not forget to tighten in proper sequence similar to installing a wheel, (bolt 1 - 3 - 2 - 4), so as not to cause undue stress on one side or part of the new pump.

- Q: looking for ideas and info to build a simple and rustic wind powered pump for a backyard pond. I don't want to use any elecricity and I would like to create something that once its made, will be trouble free and simplistic in operation. I esp. want info regarding the vane design and the method of drawing the water. I would appreciate any web sites, but I don't want to buy any pre-designed thing or plans.

- I suggest you buy one ready-made if you want trouble-free operation. Here in rural NZ they're common on farms. You can buy versions that stop pumping when your pond water has reached a certain level. They don't need any electric power and they work for years without problems. As you probably know, suction pumps can only raise water about 10 metres, but I think you can buy wind-powered pumps that push the water up from below. The vanes are connected to the piston at the bottom of the bore by a linkage.

- Q: Fire hydrant and fire pump adapter difference

- The most simple argument is outside fire hydrant water pump adapter, irrigation from.More outdoor fire hydrant, both sides of the road can be seen at any time, that is, red like a villain, there is a hat on the head. Pump adapter is not that hat.

- Q: The submersible, intermittent pump for my household water well, which is undergound out in the yard, “bangs” when it starts and stops, and vibrates the pipes when it runs. Any idea what might be causing this, or how to make it stop doing this? This all started about 5 months ago and has been getting worse.

- It sounds to me like water hammer. There are a few ways to address it, probably the easiest is to add an expansion tank. To find out, try connecting a garden hose somewhere in the system, preferably a cold water pipe. Drain all the water from the hose and put a nozzle or plug on the end so the air can't escape, then turn the valve on. The air in the hose will act as a cushion and, if water hammer is the problem, you won't hear it while the hose is connected. That is not a permanent solution, just a simple test that might give you an answer. Good luck

- Q: My car broke down yesterday and is waiting to be towed to the mechanic (2000 Dodge Neon). I'm pretty sure the Timing Belt broke, but my water pump was broken in the process and leaked out lots of water. Would the timing belt break the water pump when it snapped? Or does the broken water pump lead us to a different conclusion? Any thoughts or ideas would be appreciated.Also I was reading online today about interference engines, but couldn't find a list to verify if I have one of those or not. Anyone know? Thanks!

- there is a possibility the belt wrapped around the pump and damaged it ,but i think the pump went and the timing belt went after that.never the less both will have to be replaced

- Q: There is a loud squeecking noise coming from the water pump and the serpentime belt isnt loose!I dont know how long it would take a mechanic to do the job?

- Spray some water on the belt while it's schreeching to rule the belt out. They often make noise, even when tight.

- Q: Help?Water is to be pumped to the top of a skyscraper. If the pump can create a gauge pressure (pressure above atmospheric pressure) of 8.50E+5 Pa, what is the height of the tallest building that it can service? DATA: g=9.8 m/s^2

- Natural okorder /

- Q: Hello, I have a 1996 Cavalier and it's got a small coolant leak by the water pump so I figured I'd replace it. I called around a little bit and one quote was $250. I'm sord of handy and have a few hours on Saturday is it that hard? I heard it's just a few bolts? Thanks!!

- Look in a good auto repair manual like Chiltons. The library gets them, if you don't want to buy one. Make sure there aren't any special proceedures or cautions. Clean the area and examine it well to make sure of what actually is leaking. Commonly a worn out water pump will leak through a weephole in its shaft housing where the shaft seal is- or was. Pay attention to the lengths of the bolts and if they are different sizes, be sure they go back in the right place. If the engine needs to have air bled out when refilled with coolant, read up on how to do that and execute that correctly.

Send your message to us

Petrochemical Process Pump with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords