Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Product Advantages:

OKorder's Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

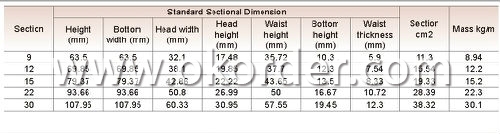

Specifications of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Packaging & Delivery of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: What is the normal tolerance of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg?

A1: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q2: Can fit in the containers of 20inches the Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: What is the impact of high-speed trains on steel rails?

- High-speed trains have a significant impact on steel rails due to the immense forces and stresses they generate. The high speeds at which these trains operate result in increased wear and tear on the steel rails, requiring regular maintenance and replacement. The primary impact of high-speed trains on steel rails is the occurrence of wear and fatigue. The weight and speed of these trains place tremendous pressure on the rails, causing them to gradually wear down over time. This wear is typically observed in the form of metal loss, surface deformation, and rail head damage. The constant friction between the train's wheels and the rails generates heat, which further contributes to the degradation of the steel rails. To mitigate the impact of high-speed trains, steel rails are made from high-strength, wear-resistant materials. These materials are designed to withstand the immense forces exerted by the trains and provide a longer service life. Additionally, the rails are often subjected to regular inspections and maintenance to identify any signs of wear or damage and prevent potential accidents. The impact of high-speed trains on steel rails also extends to the design and construction of the railway infrastructure. The tracks need to be built to accommodate the higher speeds, with reinforced foundations and specialized rail fastening systems. This additional infrastructure investment is necessary to ensure the safety and reliability of the railway system. Despite the challenges posed by high-speed trains, they also bring certain advantages to steel rails. The increased utilization of railways for high-speed transportation leads to higher demand for steel rails, which stimulates the steel industry and supports economic growth. Furthermore, the technological advancements in rail engineering driven by high-speed trains can lead to improvements in rail materials and designs, benefiting not only high-speed rail systems but also conventional rail networks. In conclusion, the impact of high-speed trains on steel rails is significant. The wear and fatigue caused by the immense forces and speeds of these trains necessitate regular maintenance and replacement of the rails. However, this impact also drives advancements in rail engineering and stimulates the steel industry, contributing to economic growth and improved rail infrastructure.

- Q: How do steel rails handle high temperatures from train friction?

- Steel rails are designed to handle high temperatures caused by train friction through a combination of factors. The steel used in rails has a high melting point, allowing it to withstand the heat generated during train operations. Additionally, rails are designed with thermal expansion in mind, meaning they can expand and contract without significant deformation or damage. Furthermore, proper maintenance practices such as regular inspection and lubrication of the rails help minimize the impact of high temperatures on their structural integrity.

- Q: What is the process of grinding steel rails?

- The process of grinding steel rails involves using specialized equipment, such as rail grinders, to remove imperfections, surface irregularities, and wear on the steel rails. This is done by applying grinding wheels to the rail surface, which rotate at high speeds and create friction to remove material. The process helps to maintain the smoothness, shape, and integrity of the rails, ensuring safe and efficient train operations.

- Q: What are the requirements for steel rail transportation logistics?

- The requirements for steel rail transportation logistics include a well-established rail network, efficient scheduling and coordination of train services, appropriate infrastructure for loading and unloading steel cargo, specialized equipment for handling and securing steel products, and strict adherence to safety protocols to ensure the secure and timely delivery of steel goods. Additionally, proper documentation, tracking systems, and communication channels are crucial for effective steel rail transportation logistics.

- Q: How are steel rails protected from chemical spills?

- Steel rails are typically protected from chemical spills through the application of specialized coatings or paints. These coatings act as a barrier between the steel rail surface and the chemicals, preventing direct contact and potential corrosion. Additionally, regular maintenance and inspections are conducted to promptly address any spills or leaks, ensuring the continued protection of the steel rails.

- Q: How are steel rails protected against extreme temperature fluctuations?

- Steel rails are protected against extreme temperature fluctuations through a process called rail stress management. This involves carefully selecting the type of steel, designing the rail profile, and employing techniques such as rail expansion joints and rail anchors to accommodate thermal expansion and contraction. Additionally, rail grinding is performed regularly to maintain the rail profile and prevent stress build-up.

- Q: What are the different types of steel rail track geometry measurements?

- The different types of steel rail track geometry measurements include gauge, alignment, curvature, elevation, and cross-level.

- Q: What are the safety measures for workers during steel rail installation?

- Some of the safety measures for workers during steel rail installation include wearing appropriate personal protective equipment such as high visibility clothing, hard hats, safety glasses, and steel-toed boots. Workers should also receive proper training on how to safely handle and install steel rails, including using lifting equipment and ensuring proper alignment and fastening. It is essential to have a designated work area that is barricaded and well-lit to prevent accidents. Regular inspections of tools and equipment should be conducted, and workers should be encouraged to report any potential hazards or unsafe conditions.

- Q: What are the safety precautions for workers handling steel rails?

- Some safety precautions for workers handling steel rails include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots. Workers should also be trained on proper lifting techniques and use mechanical aids if necessary to avoid back injuries. It is important to ensure a clear and organized work area to prevent trips and falls. Regular inspections and maintenance of equipment and tools are crucial for worker safety. Additionally, workers should be aware of potential hazards such as sharp edges or protruding objects and take necessary precautions to avoid accidents.

- Q: How do steel rails handle the effects of track settlement and heave?

- Steel rails are designed to handle the effects of track settlement and heave quite effectively. The inherent strength and flexibility of steel allow rails to withstand minor settlements and heaves without significant damage. However, in cases of substantial settlement or heave, proper maintenance and adjustments are necessary to ensure the safety and smooth operation of the railway system.

Send your message to us

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords