Heavy Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Heavy Rail

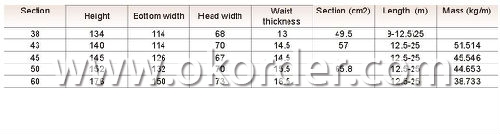

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Production Standard: GB2585-81, AREMA, DIN, JIS, EN, etc.

Length: 6M-25M as the requriement of the client

Material: 50Mn, U71Mn, 900A, R260, etc.

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

U71Mn

|

0.65—0.76 |

1.10—1.40 |

≤0.030 |

≤0.035

|

0.15-0.35

|

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Heavy Rail

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track. Be used for railway, subway, curve way, tunnel way, etc.

Packaging & Delivery of Heavy Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Heavy Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: How are steel rails maintained in desert regions?

- Steel rails in desert regions are maintained through regular inspection, cleaning, and lubrication. The extreme weather conditions in desert areas, such as high temperatures and blowing sand, can cause accelerated wear and corrosion on the rails. Therefore, maintenance crews regularly check for signs of damage, such as cracks or rust, and repair them promptly. Additionally, the rails are cleaned regularly to remove sand and debris that can hinder train operations. Lubrication is also a crucial part of maintenance, as it reduces friction between the wheels and rails, preventing excessive wear. Overall, a proactive approach to inspection and maintenance ensures that steel rails in desert regions remain in optimal condition for safe and efficient train operations.

- Q: What are the environmental considerations when using steel rails?

- Some environmental considerations when using steel rails include the extraction and production of steel, which can have a significant impact on natural resources and contribute to greenhouse gas emissions. Additionally, the maintenance and disposal of steel rails may involve the use of chemicals and energy-intensive processes. Proper waste management and recycling practices should also be implemented to minimize the environmental impact of steel rail usage.

- Q: How are steel rails protected against impact damage?

- Steel rails are protected against impact damage through the use of specialized materials and design techniques. One common method is the installation of shock-absorbing devices, such as rubber pads or resilient fasteners, which help absorb the impact energy and reduce the likelihood of damage. Additionally, proper maintenance practices, including regular inspections and repairs, are employed to identify and address any potential issues before they escalate into more significant damages.

- Q: What are the safety measures for workers during steel rail repairs?

- During steel rail repairs, workers should follow several safety measures to minimize the risk of accidents and ensure their well-being. These measures include wearing appropriate personal protective equipment (PPE) such as hard hats, safety glasses, high-visibility clothing, steel-toed boots, and gloves. Workers should also be trained on proper techniques for manual handling and lifting heavy objects, as well as how to safely operate any machinery or tools involved in the repair process. Additionally, the work area should be well-lit, and proper signage should be in place to warn others of potential hazards. Regular inspections of equipment and tools should be conducted, and workers should be encouraged to report any safety concerns or incidents immediately. Overall, adhering to these safety measures can help protect workers during steel rail repairs and prevent injuries.

- Q: Can steel rails be used in railway systems with limited track alignment options?

- Railway systems that have limited track alignment options may encounter difficulties due to space restrictions, varying terrains, or existing infrastructure. Nevertheless, steel rails can be customized in different shapes, sizes, and configurations to match specific requirements. They can be molded, curved, or adjusted to accommodate tight turns, steep slopes, or irregular track alignments. Furthermore, steel rails possess a high load-bearing capacity, enabling them to sustain heavy train traffic and endure the pressures exerted by moving trains. Consequently, they are well-suited for railway systems that have restricted track alignment options, where tracks may need to be laid in challenging landscapes such as mountains, urban areas, or cramped spaces. Additionally, steel rails promote efficient and smooth train operations by providing a stable and secure surface for trains to travel on. They minimize vibrations, decrease noise levels, and ensure a comfortable journey for passengers. This is particularly crucial in railway systems with limited track alignment options, as it helps minimize the impact on nearby areas and enhances the overall effectiveness and dependability of the system. In conclusion, steel rails are indeed a viable option for railway systems that have limited track alignment options. Their flexibility, durability, and strength make them a suitable choice for constructing efficient and dependable railway networks, even in demanding terrains or areas with space constraints.

- Q: Can steel rails be repaired in case of damage?

- Yes, steel rails can be repaired in case of damage. There are various methods and techniques available to repair damaged steel rails. One common method is known as rail welding, where damaged sections of the rail are cut out and replaced with new sections. This is done by welding the new section onto the existing rail, ensuring a secure and strong connection. Another method is called rail grinding, where the damaged rail surface is smoothed out using specialized grinding machines. This helps to remove any irregularities or defects in the rail, ensuring a smoother and safer ride for trains. Additionally, in some cases, damaged steel rails can also be repaired by employing heat treatment methods to restore their original strength and integrity. Overall, the repair of steel rails is crucial in maintaining the safety and efficiency of railway systems, and various techniques are employed to address any damage or wear that may occur over time.

- Q: How are steel rails protected from chemical spills?

- Steel rails are typically protected from chemical spills through the application of specialized coatings or paints. These coatings act as a barrier between the steel rail surface and the chemicals, preventing direct contact and potential corrosion. Additionally, regular maintenance and inspections are conducted to promptly address any spills or leaks, ensuring the continued protection of the steel rails.

- Q: What are the factors considered in determining the appropriate steel rail toughness for a railway line?

- The factors considered in determining the appropriate steel rail toughness for a railway line include the expected traffic load, train speeds, geographical conditions, and environmental factors. Additionally, the type of rolling stock, track maintenance practices, and the overall lifespan and durability requirements are also taken into account.

- Q: Can steel rails be used in railway track monitoring systems?

- Yes, steel rails can be used in railway track monitoring systems. Steel rails are commonly used in railway tracks due to their high strength and durability. They provide a stable surface for trains to run on and can also be equipped with various monitoring sensors to collect data on track conditions, such as vibrations, temperature, and stress. This data can then be used to detect and prevent potential track faults, ensuring safe and efficient railway operations.

- Q: How are steel rails protected against vandalism?

- Steel rails are typically protected against vandalism through various measures such as surveillance cameras, regular inspections, and maintenance, as well as implementing security measures like fences, barriers, and security personnel. Additionally, raising public awareness about the consequences of vandalism and enforcing strict penalties for offenders can act as deterrents.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Heavy Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords