Steel Light Rail Q235B with Multiple Specifications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Light Rail Q235B with Multiple Specifications:

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usages of Steel Light Rail Q235B with Multiple Specifications:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Steel Light Rail Q235B with Multiple Specifications:

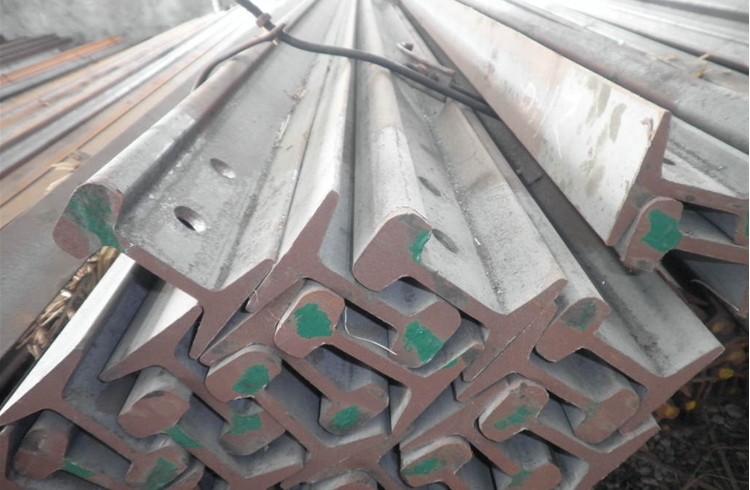

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the limitations of using steel rails in track construction?

- There are several limitations associated with the use of steel rails in track construction. 1. Cost: Steel rails can be expensive to manufacture and install compared to alternative materials like concrete or timber. The high cost of steel can make track construction projects more expensive, particularly for large-scale projects. 2. Maintenance: Steel rails require regular maintenance to ensure their durability and operational safety. Issues such as wear, corrosion, and fatigue can occur over time, leading to the need for frequent inspections and repairs. This can add to the overall maintenance costs of the rail infrastructure. 3. Noise pollution: Steel rails can generate significant noise levels, particularly when trains pass over them at high speeds. This can be a concern for residents living near railway lines as the noise can be disruptive and affect their quality of life. Additional measures, such as noise barriers, may need to be implemented to mitigate this issue. 4. Environmental impact: Steel production has a significant environmental impact, particularly in terms of energy consumption and carbon emissions. The extraction of raw materials, such as iron ore and coal, for steel production can contribute to deforestation, air pollution, and greenhouse gas emissions. Therefore, the use of steel rails in track construction may not be the most sustainable choice from an environmental perspective. 5. Weight limitations: Steel rails have a specific weight limit that they can support. This can restrict the size and weight of trains that can operate on the tracks. If heavier trains need to be accommodated, additional reinforcement or upgrades may be required, adding to the overall costs of the project. 6. Limited flexibility: Steel rails have limited flexibility compared to other materials like concrete. This rigidity can result in a less comfortable ride for passengers and increased wear and tear on the tracks. In areas prone to seismic activity or where track alignment needs to be adjusted frequently, the use of steel rails may not be the most suitable option. Overall, while steel rails have been widely used in track construction due to their strength and durability, they do have limitations in terms of cost, maintenance requirements, noise pollution, environmental impact, weight restrictions, and flexibility. These factors need to be carefully considered when deciding on the most appropriate material for track construction projects.

- Q: How do steel rails contribute to the overall speed of train travel?

- Steel rails contribute to the overall speed of train travel in several ways. Firstly, steel is an extremely durable and robust material, capable of withstanding heavy loads and repeated stress. This allows trains to travel at higher speeds without compromising safety or causing excessive wear and tear on the tracks. Secondly, steel rails provide a smooth and stable surface for the train wheels to roll on. The precision and flatness of the rails allow for minimal friction between the wheels and the tracks, reducing energy loss and enabling trains to maintain higher speeds. This smooth surface also ensures a comfortable ride for passengers, as it minimizes vibrations and jolts. Moreover, steel rails are designed to provide maximum grip and traction for the train wheels. The rail profile, consisting of a head, web, and base, is carefully engineered to optimize the contact area between the wheels and the tracks. This enhances the train's ability to accelerate and decelerate efficiently, ultimately contributing to its overall speed. Additionally, steel rails are manufactured to precise specifications, ensuring consistent track geometry. This uniformity is essential for maintaining the correct alignment and level of the tracks, preventing any irregularities that could hinder train speed or stability. Moreover, steel rails are regularly inspected and maintained to ensure their integrity, further enhancing the safety and speed of train travel. In conclusion, steel rails play a crucial role in the overall speed of train travel. Their durability, smoothness, traction, and precision contribute to reduced friction, efficient acceleration and deceleration, and a stable and comfortable ride for passengers.

- Q: How are steel rails protected from erosion?

- Steel rails are protected from erosion through a process called galvanization. This involves coating the rails with a layer of zinc, which acts as a sacrificial barrier against corrosion and erosion. Additionally, regular maintenance and inspection help identify and address any potential issues that may lead to erosion.

- Q: U71Mn what does "U" mean in the rail?

- U is the rail steel number.

- Q: How do steel rails handle heavy rainfall or flooding?

- Steel rails are generally resistant to heavy rainfall or flooding due to their strong and durable nature. The smooth surface and non-porous nature of steel rails allow rainwater to easily run off the track, preventing the formation of puddles. Additionally, steel rails are typically elevated from the ground, which further reduces the chances of water accumulation. In the event of heavy rainfall or flooding, steel rails are designed to withstand the increased water flow and pressure. They are usually built with a slight slope or camber, which aids in draining the water away from the tracks. This design feature helps to prevent any potential damage or disruption to train operations. Moreover, steel rails are highly resistant to corrosion and rust, which makes them even more suitable for handling heavy rainfall or flooding. The combination of the steel's strength and corrosion resistance ensures that the rails remain intact and functional, even under extreme weather conditions. However, it is worth mentioning that while steel rails themselves can handle heavy rainfall or flooding, the surrounding infrastructure, such as bridges or culverts, may be more susceptible to damage. In such cases, proper maintenance and regular inspections are crucial to ensure the safe and reliable operation of rail networks during and after periods of heavy rainfall or flooding.

- Q: How are steel rails protected from damage caused by wildlife?

- Steel rails are protected from damage caused by wildlife through various measures. One common method is the use of wildlife exclusion fences or barriers. These fences are designed to prevent animals from accessing the railway tracks, thus minimizing the risk of damage. The fences are typically constructed using materials that are difficult for animals to climb or burrow under, such as chain-link or woven wire mesh. Additionally, certain areas prone to wildlife crossings may have specialized wildlife crossings or underpasses built specifically for animals to safely cross the tracks without causing damage. These crossings often include natural elements like vegetation or water sources to attract wildlife away from the tracks. Furthermore, many railway companies have implemented monitoring systems to detect the presence of wildlife near the tracks. These systems may utilize infrared or motion sensors to alert train operators of any potential hazards in real-time. By being aware of the wildlife's presence, train operators can take necessary precautions to avoid collisions or damage. In some cases, wildlife deterrents such as noise or visual deterrents may also be used. These deterrents are designed to startle or discourage animals from approaching the tracks, reducing the likelihood of damage. Overall, a combination of wildlife exclusion measures, crossings, monitoring systems, and deterrents work together to protect steel rails from damage caused by wildlife. These efforts prioritize both the safety of wildlife and the smooth operation of the railway network.

- Q: How do steel rails contribute to the smooth running of trains?

- Steel rails contribute to the smooth running of trains in several ways. Firstly, steel is a strong and durable material that can withstand the weight and impact of heavy trains, maintaining their stability and preventing derailments. The smooth surface of steel rails reduces friction, allowing trains to move more efficiently and at higher speeds. Additionally, the precise alignment and consistent spacing of steel rails ensure that the wheels of the train stay on track, resulting in a smoother and safer journey for passengers.

- Q: Are steel rails subject to warping or bending?

- Yes, steel rails are subject to warping or bending under certain conditions. Steel rails are designed to be strong and rigid to support the weight of trains and withstand the forces of moving trains. However, extreme temperature fluctuations, heavy loads, and improper installation or maintenance can cause steel rails to warp or bend. One common cause of warping or bending in steel rails is thermal expansion and contraction. When the temperature changes, steel rails can expand or contract, which can lead to warping. For example, during hot weather, the rails may expand and curve upwards, creating a kink in the track. Similarly, during cold weather, the contraction of steel rails can cause them to bend downwards, resulting in a dip or depression in the track. Heavy loads, such as those carried by freight trains or high-speed trains, can also cause steel rails to bend or deform. If the load exceeds the weight-bearing capacity of the rail, it can lead to permanent deformation or even rail failure. Improper installation or maintenance practices can also contribute to the warping or bending of steel rails. For example, if the rails are not properly aligned, they can experience excessive stress and eventually deform. Similarly, lack of regular maintenance, such as failure to address track defects or replace worn-out rails, can result in warping or bending over time. To mitigate the risk of warping or bending, engineers and rail operators take several measures. They carefully design the rail systems to accommodate thermal expansion and contraction, using techniques such as expansion joints or continuous welded rail to allow for movement. Regular inspections and maintenance programs are implemented to identify and address any track defects or worn-out components that could lead to deformation. Additionally, rail operators monitor and control the loads carried by trains to ensure they stay within the limits specified for the rails. In summary, while steel rails are designed to be strong and rigid, they are subject to warping or bending under certain conditions such as extreme temperature changes, heavy loads, and improper installation or maintenance practices. However, with proper design, maintenance, and monitoring, the risk of warping or bending can be minimized to ensure the safety and efficiency of rail transportation systems.

- Q: What are the environmental risks associated with steel rail transportation?

- There are several environmental risks associated with steel rail transportation. One of the major concerns is air pollution. Rail transportation relies heavily on diesel locomotives, which emit greenhouse gases such as carbon dioxide and nitrogen oxide. These emissions contribute to climate change and air pollution, which can have detrimental effects on human health and the environment. Another environmental risk is the potential for spills or leaks of hazardous materials during transportation. Railways are often used to transport chemicals, petroleum products, and other hazardous materials, and accidents can occur leading to spills that can contaminate soil and water sources. These spills can have long-lasting effects on ecosystems and pose risks to human health. The construction and maintenance of rail infrastructure can also have environmental impacts. Deforestation and habitat destruction may occur during the construction of new rail lines, especially in areas with sensitive ecosystems. Additionally, the mining and production of steel for rail tracks can contribute to deforestation, water pollution, and greenhouse gas emissions. Noise pollution is another concern associated with rail transportation. Trains can produce high levels of noise, especially when passing through residential areas, disrupting the peace and well-being of nearby communities and wildlife. Lastly, the energy consumption and resource extraction required for steel rail transportation contribute to overall resource depletion. The production and maintenance of rail infrastructure require significant amounts of energy and raw materials, adding to the strain on natural resources. However, it is important to note that compared to other modes of transportation such as road or air, steel rail transportation is generally considered more environmentally friendly. Trains are more fuel-efficient than trucks and airplanes, and they can transport large volumes of goods, reducing the number of vehicles on the road and, consequently, reducing congestion and emissions. Additionally, rail transportation can help reduce dependence on fossil fuels and promote the use of renewable energy sources such as electric or hydrogen-powered trains. To mitigate these environmental risks, there is a need for continuous improvement in technology and infrastructure to reduce emissions and increase energy efficiency. Additionally, stricter regulations and enforcement regarding hazardous material transportation and spill prevention can help minimize the risks associated with rail transportation.

- Q: High speed rail runs so many trains a day, what about rail wear?

- Also, in the upper rail, the layer and is contacted with a wheel, is adding another metal, indium, it added to the rail on the part of the hardness of the case, even has some toughness, the train wheel is very important, it and the "tire" contact, the collision, there will be some flexibility, to ensure the safe operation of the train.

Send your message to us

Steel Light Rail Q235B with Multiple Specifications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords