Mine Engineering New Design Sewage Pump Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

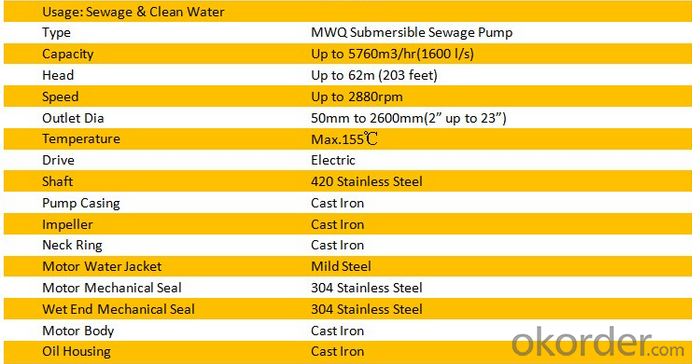

Specification

Mine Engineering New Design Sewage Pump Made in China

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

My company has organized product research and development team, experienced high, intermediate technical staff.

Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.

Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

My company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.

Relevant product standards (enterprise), metrology, standardization management system, etc.,

have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and aftersales service, are performed according to the system management standard.

Application

This series pump is widely used for sewage treatment of city construction discharge for architecture projects, hotel, mine, pond, dyeing and printing, paper making and textile industries.

It is the ideal tool for transportation of sludge, slurry, living sewage, feces and stale wastes, solid grains fiber, paper chips, sandy soil etc.

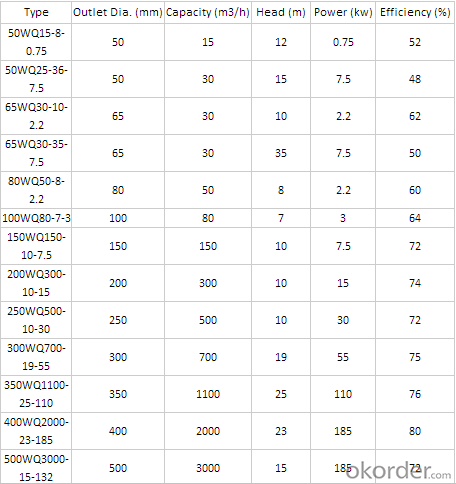

Model Description

100 WQ 50-30-3

100: Drain aperture (mm)

WQ: Submersible sewage pump

50: Capacity (m3/hr)

30: Head (m)

3: Power (kW)

Operations Conditions

1. The medium temperature should not be over 60oC, the density 1200Kg/m3, and the pH value within 5-9.

2. During running, the pump must not be lower than the permitted lowest liquid level.

3. Rated voltage 380 V, rated frequency 50 Hz. The motor can run successfully, only under the condition the deviations of both rated voltage and frequency are not over ± 5%.

4. The maximum diameter of the solid grain going through the pump has not to be larger than 50% of that of the pump outlet.

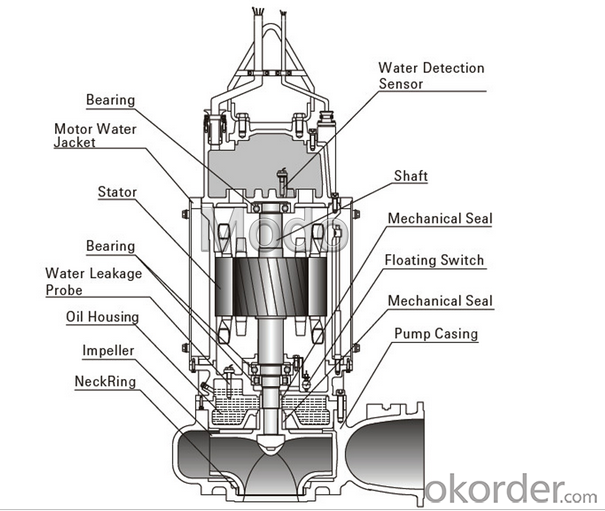

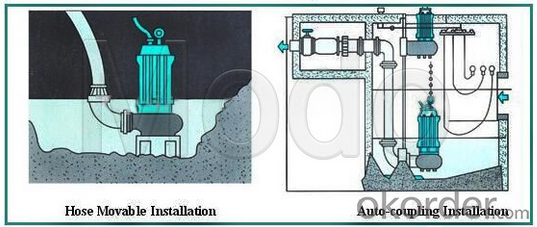

Pictures Show

Trading market

Transportation

- Q: It is known that it takes an hour to pump water, and also to know the head. How does the pump power need to be calculated? What's the formula?

- A 15kw pump, know how to calculate the head pumping water for an hour (if the head is 10 meters)Lift: MFlow rate: kg / sec (general water pump is cubic / hour, if 10 cubic hour / hour: 2.7 kg / sec)Efficiency: average 60%15000/102*0.6=88 kilograms per second88/10=8.8 kg / sec8.8*3600=31680 kg / h=31.6 cubic / hour

- Q: What is the meaning of "ETA" in pump selection table, the unit is%; and what does "NPSH" mean? The unit is m. Is in the south water pump performance curve appeared, please refer to the master, and now thank you.

- Water pump selection table "ETA" is the meaning of efficiency. NPSH refers to the pump's cavitation margin.ETA is abbreviated as "efficient ratio", and Chinese means "water efficiency". The efficiency of the pump here is generally referred to as the efficiency of the pump design point because the actual efficiency of the pump varies with the pump operating conditions. The efficiency of the ETA can also be interpreted as the efficiency of the pump at the rated lift (or rated flow).

- Q: What are the conditions for the series and parallel connection of the pumps?

- Water pumps in series require equal flow, and the latter should be able to withstand the pressure of two pumps and.The parallel pump requires the pump with equal lift head, and the outlet pipe in parallel shall be chosen according to the flow rate of two pumps.

- Q: how do you check the water pump? We started the engine with water running through the bunny ears and no water is running out.

- you cant really check the water pump. A lot of times city water is not enough pressure to have it pee the best thing to do is to take it to the lake and back it in the water and test it. Also try to apply pressure to the flush attachment and make sure its sealing correctly. If it wont pump in the lake, then most likely the pump is bad or the pee tube is clogged. take something thin and slide it into the hole and make sure its not clogged

- Q: I want to buy a tree spraying rig for my property but would like to know its theoretical capabilities first. The rig has a gas powered diaphragm pump capable of delivering 20 GPM @ a maximum pressure of 300 psi. The hose coming from the pump is 150' long and is 0.75in diameter. It has a solid stream nozzle that measures 0.1875in diameter. What would the maximum theoretical elevation that this setup could deliver a steady stream of water? The nozzle would be aimed at between 45 and 60 degrees from horizontal.

- well water exerts about 1 atm pressure (15psi) for each 33 feet of depth so 300psi is about 10 atm meaning that your pump could support a column some 330ft high then figure what pressure you would need to make your spray effective and subtract 33ft per 15psi this is only a ballpark estimate losses in hoses will be significant

- Q: 50 meters deep well with what water pump: home?

- For deepwater submersible pumps, ordinary submersible pumps are inefficient.

- Q: I have an 02 Gran Prix and my water pump is going out. With the recession I don't have the money to take it in. So can anyone give step by step instructions to help me fix it. I am a do it yourself kinda of guy so I am mechanically inclined. What tools will I'll need? is there a timing chain? How long will you think it will take me? Any thing i should pay attention to? How can I measure the pounds of torque that I put on the bolts or what tool will I'll need? Please help!!!

- WP replacement mini-writeup 1. Empy Coolant from Radiator drain 2. Remove SC and Acc. belts 3. Remove the coolant resevoir tank 3. Remove the Idler pulley with a 15mm 4. Remove the 4 WP pulley bolts with a 8mm 5. Remove the 2 Power Steering Pump bolts with a 13mm(bolts are at 12:00 and 6:00 accessable through the PS pulley holes) 6. Push PS pump 1 inch to the side 7. Remove all 8 WP bolts with a 13mm and a 10mm(3 are 13mm/5 are 10mm) 8. Collect extra coolant until flow stops(a few cups) 9. Apply RTV to both sides of the gasket and WP bolts 10. WP bolts should be torqued to 11lbs+80*/Idler pulley bolt at 36lbs/WP pulley bolts at ~9lbs 11. Reinstall everything and fill the coolant back up 12.

- Q: my marine engine doesnt pump water can you tell me some faults can be thanks vic

- Depends on what engine and what pump check the impeller to see if it is bad.

- Q: my car ran hot a few times, its a 2006 chevy impala LS with about 50k miles.I do alot of driving but never had a problem until now. I took it to get an oil change and they said that I need a new water pump. I really dont know what that means but im afraid to drive my car until i get a new pump. i called around a few auto places and no one has the part. I called the chevy dealer and they said part and labor is $600. any suggestions of other places i can check for the part? can i still drive my car in the mean time? is it safe?are water pumps usually that expensive?

- Actually a re-manufactured water pump costs less than $70.00 at any auto parts store. Any private mechanic will change it for a lot less than $600.00. If you don't have a large water pump weep hole leak with the associated loss of coolant do the following: For the time being you can cheat your cooling system's intimate standard 16 PSI (pounds per square inch) by going to Carquest and buying a 4 - 8 lb. radiator pressure cap. Change the cap when the motor and cooling system is stone cold. After installing it try not using your car's air conditioning system. It will raise the systems heat slightly. It's the pressure in the cooling system that causes a higher leak rate of the water pump. Keep an eye on the coolant level in the coolant recovery tank. Get the water pump taken care of before the snow flies!

- Q: My water pump broke on my volkswagen golf tdi so I took it to a garage. He charged me ?250 for a new pump and fitting. When I came to collect it he showed me the broken water pump, when I asked if I could keep the broken pump that was taken out of my car he said that there would be quite a quot;heftysurcharge for me to take it with me because they have to send them back to Volkswagen. I thought it was a bit strange. Is that normal?

- they shouldnt charge u since it technically trash but ive heard car manafactures buy back parts to refurbish them and resale them maybe he just wanted the money from not being able to do that

Send your message to us

Mine Engineering New Design Sewage Pump Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords