Monolithic Refractories Mesh Shape Castable for Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mesh Shape Castable For Fireplace and Industrial Furnace

Product Description:

Mesh shape castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by the clients. The Mesh shape castables are used high purity raw materials and additives as the main material, and made of under superfine powder adding technology.

Product Advantages:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, also has a fine working ability.They should be used with the same material products.They are widely used in various kinds of kiln lining.Such as boiler, blast furnace hot blast stove, heating furnace, ceramic kiln, etc.Furnaces of metallurgy industry, heat treatment furnace. Furnace of incineration of garbage, recirculating fluidized bed furnace. Furnaces of chemical industry and construction industry.

Product Applications:

For feature of Mesh shape castable, they have excellent abrasion resistance, thermal shock resistance, high-temperature resistance, anti-corrode and have high intensity.

Designed for refractory lining of blast furnace iron and slag runners, skimmers and soon

They can be used in troughs of small and mid size BFs and in all positions of the troughs where fast tapping is required.

Main Product Features:

1. High refractoriness, High refractoriness under load.

2. High density, low porosity.

3. Good slag resistance and corrosion resistance.

4. High strength and wear resistance.

5. Good resistance to flake performance.

6. Good thermal shock stability.

7. Scouring resistance

8. Good hot strength.

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

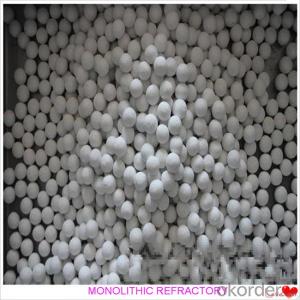

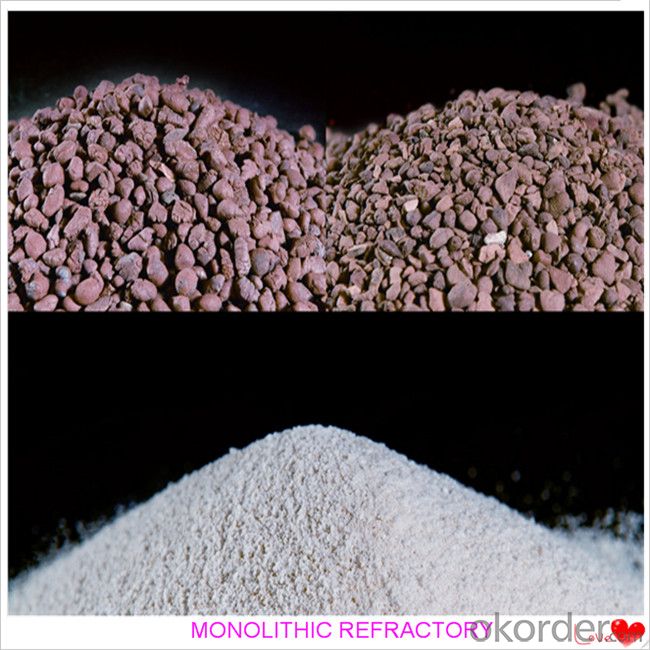

Product Picture:

- Q: How do monolithic refractories withstand the chemical attacks in copper smelting applications?

- Monolithic refractories have the ability to withstand chemical attacks in copper smelting applications due to their unique properties and composition. These refractories are specifically designed to resist the harsh and corrosive environment found in copper smelting processes. Firstly, monolithic refractories are made from high-quality materials such as alumina, silica, and magnesia, which have high melting points and are chemically stable. These materials are carefully selected to ensure they can withstand the corrosive effects of copper smelting, such as the presence of sulfur compounds and acidic gases. The refractory's composition also includes various additives and bonding agents that enhance its resistance to chemical attacks. Additionally, monolithic refractories have excellent thermal shock resistance, meaning they can withstand rapid temperature changes without cracking or spalling. In copper smelting applications, the extreme temperatures involved can cause thermal stress on the refractory lining. The refractories' ability to withstand these temperature fluctuations is crucial in preventing the formation of cracks and ensuring their long-term performance. Furthermore, monolithic refractories have a dense and compact structure, which provides an effective barrier against the penetration of molten copper and other corrosive substances. This dense structure prevents the chemical attacks from penetrating the refractory lining, thus ensuring its durability and longevity. Moreover, monolithic refractories offer superior erosion resistance, which is essential in copper smelting applications where high-velocity gases and molten metal flows can cause erosion of the refractory lining. The refractory's erosion resistance prevents the degradation of the lining and maintains its structural integrity. Overall, monolithic refractories are specially designed to withstand the chemical attacks encountered in copper smelting applications. By utilizing high-quality materials, incorporating additives, and possessing excellent thermal shock resistance, density, and erosion resistance, these refractories provide a reliable and durable lining that can withstand the harsh conditions of copper smelting processes.

- Q: What are the main factors affecting the thermal expansion of monolithic refractories?

- The main factors affecting the thermal expansion of monolithic refractories include the chemical composition of the refractory material, the temperature at which it is exposed, and the rate at which it is heated or cooled. Other factors such as the presence of impurities, the porosity of the material, and the type of bonding agents used can also influence the thermal expansion behavior of monolithic refractories.

- Q: What are the key trends in the use of monolithic refractories in the iron and steel industry?

- It is worth noting that there are several notable trends in the use of monolithic refractories in the iron and steel industry. First and foremost, there is an increasing demand for monolithic refractories due to their superior performance characteristics in comparison to traditional brick refractories. Monolithic refractories provide higher thermal shock resistance, superior insulation properties, and improved resistance to chemical attacks. As a result, they are being used more extensively in various applications within the iron and steel industry. Secondly, there is a shift towards the utilization of low-cement and ultra-low cement castables in monolithic refractories. These materials contain a reduced amount of cement, leading to enhanced refractory properties such as increased strength, better corrosion resistance, and improved resistance to thermal spalling. This trend is driven by the need to enhance the overall efficiency and longevity of refractory linings in iron and steel manufacturing processes. Another significant trend is the development of advanced monolithic refractories that prioritize sustainability and environmental performance. The iron and steel industry is facing mounting pressure to reduce its carbon footprint and minimize its impact on the environment. Consequently, there is a growing emphasis on the use of environmentally friendly binders and additives in monolithic refractories. These novel materials not only offer excellent refractory properties but also contribute to the industry's sustainability objectives. Moreover, there is an increasing focus on the development of monolithic refractories capable of withstanding extreme operating conditions. Iron and steel manufacturing processes involve high temperatures, aggressive chemical environments, and severe mechanical stresses. Consequently, there is a need for monolithic refractories that can withstand these harsh conditions without compromising their performance. The industry is investing in research and development to create refractories that exhibit exceptional resistance to thermal shock, abrasion, and erosion. Lastly, there is a growing adoption of digital and smart technologies for the monitoring and maintenance of monolithic refractories. Advances in sensor technology and data analytics have made it possible to collect real-time data on the condition and performance of refractory linings. This enables proactive maintenance, early detection of potential issues, and optimization of refractory usage, ultimately leading to improved operational efficiency and cost savings. In conclusion, the use of monolithic refractories in the iron and steel industry is witnessing key trends such as the demand for superior performance, the shift towards low-cement and ultra-low cement castables, the development of sustainable materials, the focus on extreme operating conditions, and the adoption of digital and smart technologies for monitoring and maintenance. These trends reflect the industry's continuous efforts to enhance the efficiency, durability, and environmental sustainability of refractory linings in iron and steel manufacturing processes.

- Q: How do monolithic refractories help in enhancing the durability of iron and steel furnaces?

- Monolithic refractories play a crucial role in enhancing the durability of iron and steel furnaces due to their unique properties and characteristics. These materials are designed to withstand extremely high temperatures and harsh conditions, making them ideal for lining the furnaces. Firstly, monolithic refractories have excellent thermal resistance, meaning they can withstand extreme heat without losing their structural integrity. Iron and steel furnaces operate at incredibly high temperatures, sometimes exceeding 2,000 degrees Celsius. Regular bricks or other materials would not be able to withstand such temperatures, leading to frequent repairs and maintenance. Monolithic refractories, on the other hand, can handle these extreme temperatures without deteriorating, thus enhancing the durability of the furnaces. Secondly, monolithic refractories have high resistance to chemical attack. In iron and steel production, the materials being processed often contain various impurities and aggressive chemicals. These substances can react with the furnace lining and cause corrosion or erosion over time. However, monolithic refractories have a high resistance to chemical attack, ensuring that the lining remains intact and durable even in the presence of corrosive elements. Furthermore, monolithic refractories have excellent mechanical strength and abrasion resistance. Iron and steel furnaces experience mechanical stress and abrasion due to the movement of raw materials, the stirring of molten metal, and the tapping of the furnace. The lining needs to withstand this constant wear and tear without breaking or cracking. Monolithic refractories have superior mechanical strength and can resist abrasion, ensuring that the furnace remains durable and functional for a longer period. Additionally, monolithic refractories offer exceptional thermal shock resistance. The lining of iron and steel furnaces is subjected to rapid temperature changes during various stages of production. These temperature fluctuations can cause thermal stress and lead to cracking or spalling of the lining. However, monolithic refractories have low thermal conductivity and can withstand thermal shock, preventing any damage to the furnace lining and enhancing its durability. In summary, monolithic refractories help enhance the durability of iron and steel furnaces by providing excellent thermal resistance, high resistance to chemical attack, superior mechanical strength and abrasion resistance, as well as exceptional thermal shock resistance. These properties ensure that the furnace lining remains intact, withstands extreme temperatures, and resists the corrosive and abrasive nature of the materials being processed, ultimately prolonging the life of the furnace and reducing the need for frequent repairs or replacements.

- Q: How do monolithic refractories impact the quality and performance of iron and steel products?

- The quality and performance of iron and steel products rely heavily on monolithic refractories. These refractories are designed to withstand extreme temperatures and harsh conditions, making them indispensable in the iron and steel industry. To begin with, monolithic refractories contribute to the overall quality of iron and steel products by providing exceptional thermal insulation. They help maintain a consistent and controlled temperature during the manufacturing process, which is especially crucial in blast furnaces where temperatures can reach up to 2,000 degrees Celsius. By effectively insulating the furnace walls, monolithic refractories minimize heat loss and ensure efficient energy utilization. As a result, the products have higher quality and improved mechanical properties. Additionally, monolithic refractories offer superior resistance to chemical and physical wear. In the steelmaking process, the molten metal and slag can be highly corrosive, leading to erosion and deterioration of the refractory lining. However, monolithic refractories are engineered to withstand such aggressive environments, providing excellent resistance to chemical attack and mechanical stress. By preserving the integrity of the lining, they prevent contamination and extend the lifespan of the furnace or ladle, ultimately enhancing the quality of the final iron and steel products. Moreover, monolithic refractories allow for greater design flexibility and ease of installation. Unlike traditional refractory bricks that require precise placement and fitting, monolithic refractories can be applied as a single, cohesive material. This enables the creation of more intricate shapes and structures, optimizing furnace design and enhancing thermal efficiency. Additionally, the ease of installation reduces downtime during maintenance and repairs, ensuring uninterrupted production and minimizing disruptions to the manufacturing process. In conclusion, monolithic refractories have a significant impact on the quality and performance of iron and steel products. They provide exceptional thermal insulation, resist chemical and physical wear, and offer greater design flexibility. By maintaining consistent temperature environments, preventing contamination, and enabling efficient production processes, monolithic refractories contribute to the production of high-quality iron and steel products that meet the rigorous demands of various industries.

- Q: What are the advantages of using low-cement castables in the iron and steel industry?

- There are several advantages of using low-cement castables in the iron and steel industry. Firstly, low-cement castables have a lower water content, which leads to better refractoriness and higher strength, enabling them to withstand high temperatures and thermal shocks experienced in iron and steel manufacturing processes. Secondly, low-cement castables exhibit excellent flowability and workability, allowing for easier installation and shaping. This results in reduced labor and time required for installation, leading to cost savings. Moreover, low-cement castables have a reduced porosity, which enhances their resistance to slag and metal penetration during the iron and steel production processes. This property improves the lining's durability and extends its service life, reducing maintenance and downtime. Additionally, low-cement castables offer superior mechanical properties, such as higher abrasion resistance and better thermal conductivity, making them ideal for various applications in the iron and steel industry, including ladles, tundishes, and blast furnaces. Overall, the advantages of using low-cement castables in the iron and steel industry include enhanced refractoriness, increased strength, improved workability, reduced porosity, and superior mechanical properties, ultimately resulting in improved efficiency, cost-effectiveness, and longer-lasting linings.

- Q: How do monolithic refractories impact the overall productivity of iron and steel operations?

- Monolithic refractories play a crucial role in enhancing the overall productivity of iron and steel operations. These refractories are specially designed to withstand extreme temperatures, chemical reactions, and mechanical stress that occur during the production process. One significant impact of monolithic refractories on productivity is their ability to reduce downtime and increase operational efficiency. The high thermal conductivity and resistance to thermal shock of these refractories enable them to maintain stable temperatures within the furnace, preventing sudden temperature fluctuations that can cause equipment failure and production delays. This, in turn, ensures a continuous and uninterrupted production process, leading to increased productivity. Moreover, monolithic refractories offer superior corrosion resistance, preventing the erosion and degradation of furnace linings. This resistance to chemical attacks from molten metals and slag helps prolong the lifespan of the refractory lining, reducing the frequency of repairs and replacements. Consequently, the reduced maintenance requirements translate into less downtime and higher productivity for iron and steel operations. Additionally, monolithic refractories facilitate faster installation and repair processes compared to traditional brick refractories. Their fluid-like nature allows for easy application and shaping, resulting in shorter installation and curing times. This quick turnaround time minimizes production interruptions during repairs or maintenance, further enhancing overall productivity. Furthermore, the use of monolithic refractories can optimize energy consumption in iron and steel operations. Their excellent insulation properties help retain heat within the furnace, reducing heat loss and energy waste. This leads to improved energy efficiency and cost savings, contributing to increased productivity and profitability. In summary, monolithic refractories have a significant impact on the overall productivity of iron and steel operations. Their ability to withstand extreme conditions, reduce downtime, resist corrosion, facilitate quick repairs, and optimize energy consumption all contribute to improved efficiency and productivity in the industry.

- Q: How are monolithic refractories used in the iron and steel industry?

- Monolithic refractories are used in the iron and steel industry for various applications such as lining furnaces, ladles, and tundishes, as well as repairing and maintaining the refractory linings. These refractories are often in the form of a dense, one-piece structure that can withstand high temperatures, thermal shocks, and chemical attacks from molten metals and slag. They provide insulation, corrosion resistance, and mechanical strength to the equipment and structures used in iron and steel production, ensuring efficient and reliable operations.

- Q: What are the common applications of monolithic refractories in blast furnaces?

- Monolithic refractories are commonly used in blast furnaces for various applications such as lining and repairing the hearth, taphole, and slag line, as well as for hot repairs and maintenance. These refractories provide high-temperature resistance, erosion and corrosion resistance, and thermal shock resistance, thereby ensuring the efficient and reliable operation of blast furnaces in the iron and steel industry.

- Q: What are the key properties of pumpable refractories used for monolithic refractory applications?

- The key properties of pumpable refractories used for monolithic refractory applications include high flowability, good workability, excellent bonding strength, and high resistance to thermal shock. These pumpable refractories should also possess good pumpability and be able to withstand the intense heat and mechanical stress in the application environment. Additionally, they should have low water demand, high chemical resistance, and the ability to maintain their properties even after exposure to high temperatures.

Send your message to us

Monolithic Refractories Mesh Shape Castable for Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords