Monolithic Refractories Castable Block for Iron and Steel Industry Furnaces

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Castable Block for Fireplaces and Industrial Furnaces

Product Description:

Castable Block is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by clients. Castables use high purity raw materials and additives as the main material, and are made with superfine powder adding technology.

Product Features:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, and also excellent working ability. If should be used with the same material products.

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

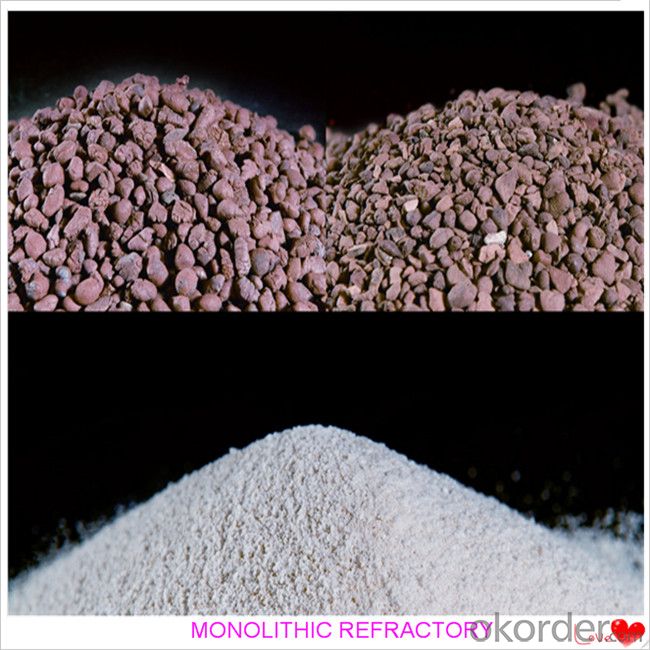

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: How do monolithic refractories impact the quality of iron and steel products?

- Monolithic refractories play a crucial role in enhancing the quality of iron and steel products. These refractories are used to line the furnaces, ladles, and other equipment involved in the production process. By providing excellent thermal insulation and resistance to high temperatures, monolithic refractories help maintain stable and controlled heating conditions, which is essential for achieving desired chemical compositions and microstructures in iron and steel. Moreover, these refractories minimize heat loss, prevent contamination, and reduce the formation of impurities, thus ensuring the production of high-quality and defect-free iron and steel products.

- Q: What are the advantages of using low-cement castables in the iron and steel industry?

- There are numerous benefits associated with the utilization of low-cement castables in the iron and steel sector. To begin with, low-cement castables necessitate less water compared to traditional castables. Consequently, the installation process becomes faster and more efficient due to the reduced water requirement. Moreover, the lower water content results in enhanced strength development and shorter drying time, facilitating faster turnaround times during production. In addition, low-cement castables exhibit exceptional resistance to extreme temperatures and thermal shocks. Given the high temperatures prevalent in the iron and steel industry, these castables possess excellent refractory properties that enable them to withstand such harsh conditions. Consequently, the refractory lining enjoys an extended service life, reducing the need for frequent repairs or replacements. Furthermore, low-cement castables demonstrate remarkable mechanical strength and abrasion resistance. Given the nature of the iron and steel sector, where heavy materials and abrasive substances are handled, the refractory lining is susceptible to wear and tear. However, low-cement castables are capable of enduring these mechanical stresses, thereby enhancing the durability and longevity of the lining. Moreover, low-cement castables possess low porosity and high density, resulting in reduced permeability. Consequently, they exhibit high resistance to alkali attacks, chemical corrosion, and slag penetration, all of which are common challenges faced in the iron and steel industry. By employing low-cement castables, the risk of refractory failure caused by these corrosive elements is minimized. Lastly, low-cement castables contribute to improved energy efficiency. Their lower thermal conductivity ensures that less heat is conducted through the refractory lining, leading to reduced heat losses. This, in turn, translates into energy savings, as less heat is wasted and more heat is retained within the system. The significance of this advantage is particularly evident in the iron and steel industry, where energy costs can be substantial. In conclusion, the use of low-cement castables in the iron and steel sector offers a multitude of advantages, including reduced water requirement, superior thermal resistance, enhanced mechanical strength, improved resistance to chemical corrosion, and increased energy efficiency. These benefits contribute to overall cost savings, heightened productivity, and improved operational performance in the iron and steel manufacturing process.

- Q: What are the typical operating temperatures for monolithic refractories?

- The typical operating temperatures for monolithic refractories range from 1,100 to 1,800 degrees Celsius (2,012 to 3,272 degrees Fahrenheit), depending on the specific type and composition of the refractory material.

- Q: How do monolithic refractories contribute to the overall safety of iron and steel operations?

- Monolithic refractories play a crucial role in ensuring the overall safety of iron and steel operations. These refractories are designed to withstand extreme temperatures, chemical reactions, and mechanical stresses, providing a protective barrier to the furnaces, ladles, and other equipment used in these operations. By maintaining the integrity of the refractory lining, monolithic refractories prevent leaks, minimize the risk of thermal shock, and reduce the chances of equipment failure or accidents. This helps to safeguard the workers, prevent damage to the infrastructure, and ensure the uninterrupted production of iron and steel, thus contributing to the overall safety of the operations.

- Q: What types of monolithic refractories are commonly used in the iron and steel industry?

- In the iron and steel industry, several types of monolithic refractories are commonly used due to their high resistance to extreme temperatures and mechanical stresses. These refractories are essential for lining furnaces, ladles, and other equipment used in the production of iron and steel. One commonly used monolithic refractory in this industry is castable refractory. It is a mixture of refractory aggregates, binders, and additives that can be poured or cast into various shapes and sizes. Castable refractories are versatile and can be easily installed, making them suitable for lining large furnaces and ladles. They offer good thermal insulation and excellent resistance to thermal shocks. Another type of monolithic refractory used in the iron and steel industry is plastic refractory. It consists of a high-alumina refractory aggregate mixed with a bonding agent, usually clay. Plastic refractories have a high plasticity and can be easily shaped by hand or with a trowel. They are commonly used for repairs and patching in furnaces and ladles. Ramming refractories are also commonly employed in the iron and steel industry. These refractories are made of granular refractory materials mixed with a binder. They are installed by ramming the mixture into the desired shape using a pneumatic hammer or manual ramming tools. Ramming refractories offer high resistance to abrasion and erosion, making them suitable for lining the bottoms of furnaces and other areas subjected to intense mechanical wear. Lastly, gunning refractories are frequently used in the iron and steel industry. Gunning refractories are made of fine refractory powders mixed with water or a bonding agent. They are applied using a gunning machine, which propels the refractory material onto the surface to be lined. Gunning refractories are commonly used for repairing and maintaining the linings of ladles, tundishes, and other equipment. Overall, the iron and steel industry relies on a variety of monolithic refractories such as castables, plastics, rammings, and gunnings to ensure the reliable and efficient operation of their equipment in high-temperature environments. These refractories provide excellent thermal insulation, resistance to thermal shocks, and mechanical strength essential for the production of iron and steel.

- Q: How do monolithic refractories contribute to the overall efficiency of steel ladle operations?

- The overall efficiency of steel ladle operations can be greatly improved by the use of monolithic refractories. These refractories, which are engineered materials installed as a single structure within the ladle, offer numerous advantages that directly contribute to operational efficiency. One key benefit of monolithic refractories is their exceptional thermal insulation properties. They have a low thermal conductivity, meaning they are effective at retaining and containing heat within the ladle. This insulation helps to maintain the desired temperature of the molten steel, preventing heat loss during transportation and reducing the need for frequent reheating. By minimizing heat loss, monolithic refractories enable a more efficient use of energy resources, resulting in cost savings and improved productivity. Moreover, monolithic refractories possess a high refractoriness, meaning they can withstand high temperatures without losing their structural integrity. This is crucial in steel ladle operations, where extreme temperatures are encountered during the steelmaking process. The high refractoriness of monolithic refractories ensures that they can withstand the intense heat and avoid any damage or failure of the ladle lining. This durability translates into reduced downtime and maintenance requirements, leading to increased operational efficiency. Additionally, monolithic refractories offer excellent resistance to chemical attack. The ladles used in steelmaking come into contact with various corrosive substances, such as molten metals, slag, and fluxes. The chemical resistance of monolithic refractories prevents them from reacting with these substances, ensuring the integrity and longevity of the ladle lining. This resistance to chemical attack reduces the need for repairs and replacements, minimizing downtime and improving overall operational efficiency. Furthermore, the installation of monolithic refractories is relatively quick and straightforward compared to traditional brick linings. This ease of installation saves time and labor costs, allowing for a faster turnaround between ladle operations. It enables steel manufacturers to optimize their production schedules and enhance overall operational efficiency. In conclusion, monolithic refractories play a significant role in improving the efficiency of steel ladle operations. Their thermal insulation properties, high refractoriness, resistance to chemical attack, and ease of installation all contribute to enhanced energy efficiency, reduced downtime, and increased productivity. By choosing to use monolithic refractories, steel manufacturers can achieve optimized ladle performance and ultimately improve their steelmaking process as a whole.

- Q: How are monolithic refractories used in the iron and steel industry?

- Monolithic refractories are used in the iron and steel industry for various applications such as lining furnaces, ladles, and tundishes, as well as repairing and maintaining the refractory linings. These refractories are often in the form of a dense, one-piece structure that can withstand high temperatures, thermal shocks, and chemical attacks from molten metals and slag. They provide insulation, corrosion resistance, and mechanical strength to the equipment and structures used in iron and steel production, ensuring efficient and reliable operations.

- Q: What are the main factors affecting the corrosion resistance of monolithic refractories?

- The main factors affecting the corrosion resistance of monolithic refractories include the chemical composition of the refractory material, the temperature and atmosphere in which it operates, the physical properties of the refractory such as porosity and permeability, and the presence of impurities or aggressive agents. Additionally, the design and installation of the refractory lining, as well as the operational practices and maintenance of the system, can also impact its corrosion resistance.

- Q: How do monolithic refractories contribute to the safety of iron and steel operations?

- Monolithic refractories play a crucial role in enhancing the safety of iron and steel operations. These refractories are made of a single, continuous material, which offers several benefits that contribute to the overall safety of the operations. Firstly, monolithic refractories provide excellent thermal insulation. They are designed to withstand high temperatures, preventing heat transfer to the surrounding environment. This insulation property helps in maintaining a safe working temperature for the operators, reducing the risk of burns or other heat-related injuries. Furthermore, monolithic refractories have high resistance to chemical attack. In iron and steel operations, various chemicals and molten metals are used, which can be corrosive and hazardous. The use of monolithic refractories as lining materials creates a protective barrier that resists the corrosive effects of these substances, preventing leaks and potential accidents. Another safety benefit is the ability of monolithic refractories to withstand mechanical stress. Steelmaking processes involve heavy machinery and equipment, which can exert significant pressure on the refractory linings. Monolithic refractories have excellent mechanical strength, which enables them to withstand these stresses and maintain their integrity. This prevents the risk of sudden failure or collapse, reducing the possibility of accidents and injuries due to falling debris. Additionally, monolithic refractories offer easy installation and repair. They can be applied as a castable or gunning material, allowing for quick and efficient lining of furnaces, ladles, and other equipment. This ease of installation reduces downtime during maintenance or repairs, minimizing the risk of accidents caused by delayed or prolonged shutdowns. In summary, monolithic refractories contribute to the safety of iron and steel operations through their excellent thermal insulation, resistance to chemical attack, ability to withstand mechanical stress, and ease of installation and repair. By providing a protective barrier, these refractories help in preventing injuries, maintaining a safe working environment, and minimizing the potential hazards associated with high temperatures, corrosive substances, and mechanical failures.

- Q: What are monolithic refractories?

- Monolithic refractories are a type of refractory material that is manufactured as a single, homogeneous unit, as opposed to being made from individual bricks or precast shapes. They are characterized by their ability to be shaped and installed in various applications without the need for joints or mortar, making them a versatile and convenient choice for lining furnaces, boilers, kilns, and other high-temperature industrial equipment. These refractories are typically composed of a mixture of refractory aggregates, binders, and additives, which are carefully selected and combined to provide the desired properties such as high temperature resistance, thermal shock resistance, and chemical durability. The aggregates used can include materials like alumina, magnesia, zirconia, and silica, while binders like clay, cement, or phosphate are added to hold the aggregates together. One of the advantages of monolithic refractories is their ability to adapt to complex shapes and designs, allowing for customized linings that can be tailored to specific equipment requirements. They are often applied by pouring, gunning, ramming, or spraying the refractory material onto the surface to be lined, allowing for quick and efficient installation. This eliminates the need for time-consuming bricklaying and jointing, reducing installation time and labor costs. Monolithic refractories are also known for their superior thermal conductivity, which enables them to withstand high temperatures and sudden temperature changes. They offer excellent insulation properties, preventing heat loss and improving energy efficiency in industrial processes. Furthermore, these refractories exhibit good resistance to chemical attack from molten metals, slags, gases, and other corrosive substances found in various industrial environments. This makes them highly suitable for applications in industries such as steel, cement, glass, petrochemical, and non-ferrous metals. In summary, monolithic refractories are a versatile and efficient solution for high-temperature applications. Their ability to be shaped and installed without joints or mortar, coupled with their excellent thermal conductivity and chemical resistance, make them a valuable choice for lining industrial equipment that operates under extreme conditions.

Send your message to us

Monolithic Refractories Castable Block for Iron and Steel Industry Furnaces

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords