Monolithic Refractories for Iron and Steel Industry:Corundum Castable for EAF Roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Corundum Castable for EAF Roof

Made as per international standards, FIREF corundum castable for EAF roof is known for its excellent corrosion and scouring resistance of iron steel, long operating life and easy execution and mending. Further, FIREF corundum castable for EAF roof can be provided in different specifications as required by the clients.

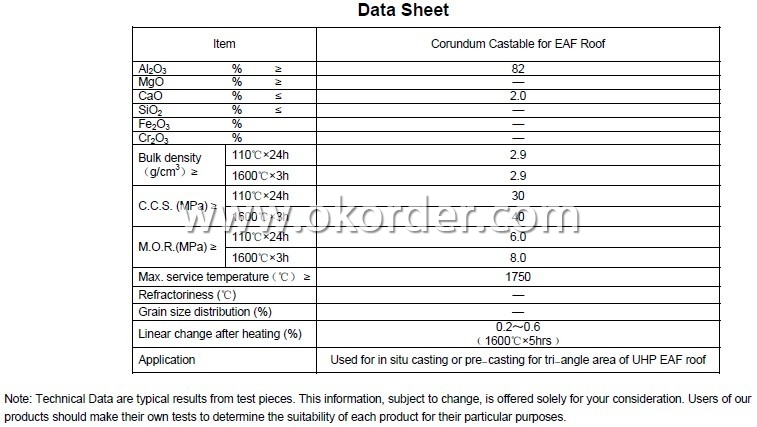

Technical data of Corundum Castable for EAF Roof

Production line and packing of Corundum Castable for EAF Roof

Feature of Corundum Castable for EAF Roof

Excellent corrosion and scouring resistance of iron steel

Long operating life

Easy execution and mending

Application of Corundum Castable for EAF Roof

FIREF corundum castable for EAF roof can be used widely for in situ casting or pre-casting for tri-angle area of UHP EAF roof.

Production Flow of Corundum Castable for EAF Roof

- Q: What are the main causes of monolithic refractory failure in the iron and steel industry?

- There are several main causes of monolithic refractory failure in the iron and steel industry. One of the primary causes is thermal cycling. The extreme temperatures experienced in iron and steel manufacturing processes, such as melting, casting, and heat treating, subject the refractory lining to significant thermal stress. This repeated expansion and contraction of the material can lead to cracking, spalling, or even complete disintegration of the refractory. Another common cause of failure is chemical attack. The iron and steel industry involves the use of various chemicals, including molten metal, slag, and gases, which can react with the refractory lining. This chemical interaction can cause erosion, corrosion, or chemical decomposition of the refractory material, leading to its failure over time. Mechanical stress is also a significant factor in monolithic refractory failure. The heavy machinery and equipment used in iron and steel production can generate vibrations, shocks, and impacts that can weaken or damage the refractory lining. Additionally, improper installation or design can result in mechanical stress concentration points, making the refractory more susceptible to failure. Furthermore, improper maintenance and operational practices can contribute to refractory failure. Inadequate cooling or heating procedures, improper drying and curing of the refractory, and insufficient cleaning and inspection can all impact the longevity and performance of the material. Lack of regular maintenance and timely repairs can exacerbate small issues, leading to more significant failures over time. Lastly, the choice of refractory material and its quality can play a significant role in failure. Selecting an inappropriate refractory for the specific application or using low-quality materials can result in premature failure. It is crucial to consider factors such as temperature range, chemical exposure, and mechanical stress when choosing the refractory lining to ensure its suitability and durability in the iron and steel industry. In summary, the main causes of monolithic refractory failure in the iron and steel industry are thermal cycling, chemical attack, mechanical stress, improper maintenance and operational practices, and the choice and quality of refractory material. Addressing these factors through proper installation, regular maintenance, and careful material selection can help mitigate refractory failures and improve the overall efficiency and productivity of iron and steel production processes.

- Q: How do monolithic refractories resist high temperatures?

- Monolithic refractories, with their unique composition and structure, are specifically designed to withstand high temperatures. Unlike traditional refractory bricks, which are made up of multiple pieces, these refractories are created from a single material or piece. The primary factor contributing to the high temperature resistance of monolithic refractories is their elevated melting point. Materials such as alumina, silica, and magnesia, which have melting points ranging from 1650°C to 2000°C, are utilized in their production. This characteristic allows the refractories to endure extreme temperatures without experiencing significant deformation or melting. Moreover, monolithic refractories possess exceptional thermal stability. They exhibit low thermal conductivity, enabling them to effectively insulate against heat transfer. As a result, these refractories can maintain their structural integrity even when exposed to rapid temperature changes or thermal shocks. Furthermore, the monolithic nature of these refractories grants them enhanced resistance to thermal stress. Unlike traditional refractory bricks, they lack joints or seams that are susceptible to thermal expansion and contraction. Consequently, they exhibit greater resistance to cracking or spalling when subjected to high temperatures. Additionally, monolithic refractories have the ability to develop a protective layer or slag on their surface when exposed to elevated temperatures. This slag acts as a barrier, preventing direct contact between the refractory material and the hot gases or molten metals. Consequently, the risk of chemical reactions or corrosion is reduced. In conclusion, the combination of high melting point, thermal stability, resistance to thermal stress, and the capacity to form a protective slag makes monolithic refractories highly effective in withstanding high temperatures. They find wide applications in various industries, including steel, cement, glass, and petrochemical, where they encounter extreme heat conditions.

- Q: How are monolithic refractories used in the repair and maintenance of ladle and tundish linings?

- Monolithic refractories are used in the repair and maintenance of ladle and tundish linings by providing a durable and heat-resistant material that can withstand the harsh conditions of molten metal handling. These refractories are applied as a single, continuous lining, eliminating the need for individual bricks or tiles, which simplifies the repair and maintenance process. They can be easily shaped and installed in the desired areas, allowing for efficient repair of damaged sections. Monolithic refractories also offer excellent resistance to thermal shock, erosion, and corrosion, ensuring the longevity and reliability of ladle and tundish linings.

- Q: What are the considerations for repairing and relining monolithic refractories?

- When it comes to repairing and relining monolithic refractories, there are several key considerations that need to be taken into account. Firstly, it is important to assess the extent of the damage or wear to the refractory lining. This can be done through visual inspection, as well as non-destructive testing techniques such as ultrasonic or thermal imaging. Understanding the severity and location of the damage will help in determining the appropriate repair or relining method. Another consideration is the type of monolithic refractory material being used. Different materials have different properties and performance characteristics, and this needs to be considered when selecting the repair method. For example, some materials may require high-temperature curing or specialized equipment for installation. The operating conditions of the refractory lining also need to be taken into account. Factors such as temperature, chemical exposure, and mechanical stress can affect the performance and longevity of the lining. The repair or relining method should be selected to ensure that it can withstand these conditions and provide long-lasting protection. Additionally, the downtime and cost implications of the repair or relining process need to be considered. Some methods may require longer curing or drying times, which can result in extended shutdown periods. It is important to weigh the benefits of the repair or relining against the potential production losses and expenses associated with the downtime. Lastly, it is crucial to follow industry standards and guidelines when repairing or relining monolithic refractories. This ensures that the repairs are done correctly and in a safe manner, minimizing the risk of future damage or failure. Consulting with refractory experts or manufacturers can provide valuable insights and guidance in this regard. In conclusion, the considerations for repairing and relining monolithic refractories include assessing the extent of damage, understanding the properties of the refractory material, considering the operating conditions, evaluating downtime and cost implications, and following industry standards and guidelines.

- Q: What are monolithic refractories and how are they different from other refractory materials?

- Monolithic refractories are a type of refractory material that are composed of a single, homogeneous structure, as opposed to being made up of multiple separate pieces. They are different from other refractory materials, such as bricks or tiles, which are assembled together to form a lining. Monolithic refractories are typically made from a combination of aggregates, binders, and additives, which are mixed together and applied in a plastic or semi-plastic state. This allows for easier installation, as they can be shaped and formed to fit the specific dimensions of the furnace or kiln. Additionally, monolithic refractories offer benefits such as better thermal shock resistance, reduced joints and seams, and improved overall performance due to their seamless nature.

- Q: How do monolithic refractories contribute to the overall reliability of iron and steel processes?

- Monolithic refractories play a crucial role in enhancing the overall reliability of iron and steel processes in several ways. Firstly, they provide excellent thermal insulation, which helps in maintaining consistent and controlled temperatures within the furnaces and other equipment involved in the production process. This ensures the stability of the process and avoids any sudden temperature fluctuations that could lead to equipment failure or product quality issues. Secondly, monolithic refractories offer high resistance to thermal shocks and mechanical stresses, which are common in iron and steelmaking operations. These refractories can withstand extreme temperatures, rapid heating and cooling cycles, and the corrosive nature of molten metals, thereby prolonging the lifespan of the equipment and reducing the frequency of repairs or replacements. Moreover, monolithic refractories have a superior ability to resist chemical attacks from molten metals, slag, and other harsh substances encountered in iron and steel processes. This resistance prevents the refractories from deteriorating or corroding over time, ensuring their integrity and preventing any contamination of the metal being produced. Lastly, the use of monolithic refractories allows for greater design flexibility and ease of installation compared to traditional brick refractories. This flexibility enables the construction of complex shapes and structures, optimizing the efficiency and productivity of iron and steelmaking processes. Overall, monolithic refractories contribute significantly to the reliability of iron and steel processes by providing excellent thermal insulation, resistance to thermal shocks and chemical attacks, and facilitating flexible design and installation options.

- Q: How are monolithic refractories different from traditional refractory materials?

- Monolithic refractories are different from traditional refractory materials in several ways. Firstly, while traditional refractory materials are typically made from bricks, blocks, or tiles, monolithic refractories are composed of a single, continuous material. This means that they do not have any joints or seams, which can be a weak point in traditional refractory structures. Secondly, monolithic refractories are much easier to install compared to traditional refractory materials. They can be easily shaped and applied in situ, allowing for greater flexibility in design and construction. In contrast, traditional refractory materials require skilled labor and more time-consuming installation methods such as bricklaying. Furthermore, monolithic refractories offer improved thermal shock resistance. Due to their continuous structure, they can better withstand sudden changes in temperature without cracking or spalling. Traditional refractory materials, on the other hand, may be more susceptible to thermal shock damage. Another advantage of monolithic refractories is their ability to provide better insulation. Their composition often includes lightweight aggregates or insulating fibers, which help to reduce heat loss and improve energy efficiency. Traditional refractory materials, while still capable of providing insulation, may not offer the same level of thermal efficiency. Lastly, monolithic refractories have the advantage of being more cost-effective. Their ease of installation, reduced labor requirements, and improved thermal performance contribute to lower overall project costs compared to traditional refractory materials. In summary, monolithic refractories differ from traditional refractory materials in terms of their continuous structure, ease of installation, improved thermal shock resistance, better insulation properties, and cost-effectiveness. These characteristics make them a preferred choice in many industries where high-temperature applications and thermal insulation are required.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish drying systems?

- Monolithic refractories improve the efficiency of ladle and tundish drying systems by providing superior thermal insulation, reduced heat loss, and increased resistance to thermal shock. These refractories have high thermal conductivity and low heat capacity, enabling faster and more uniform heating of the ladle and tundish. Additionally, their monolithic nature eliminates joints and seams that could lead to heat leakage, ensuring better heat retention and improved energy efficiency. The enhanced thermal properties of monolithic refractories contribute to quicker drying times and reduced energy consumption in ladle and tundish drying processes, ultimately improving overall system efficiency.

- Q: How do monolithic refractories improve the durability of furnace linings?

- Monolithic refractories improve the durability of furnace linings by providing a seamless and continuous structure that eliminates joints and weak points. This eliminates the risk of thermal shock and cracking, resulting in a longer lifespan for the furnace lining. Additionally, monolithic refractories offer better resistance to chemical attack, abrasion, and thermal stress, further enhancing the durability of the furnace lining.

- Q: What are the key factors to consider when designing the lining system with monolithic refractories?

- When designing a lining system with monolithic refractories, there are several key factors that need to be considered in order to ensure optimal performance and longevity of the lining. These factors include: 1. Material selection: Choosing the right monolithic refractory material is crucial. Factors such as the operating temperature, chemical environment, and mechanical stress need to be taken into account. Different monolithic refractories have varying properties and performance characteristics, so selecting the most suitable material for the specific application is essential. 2. Thermal expansion: Monolithic refractories, like any other material, expand and contract with changes in temperature. It is important to consider the thermal expansion properties of the refractory material and how it will interact with the surrounding structure. Proper expansion joints or design features should be incorporated to accommodate thermal expansion and prevent cracking or spalling. 3. Installation technique: The method of installation plays a critical role in the performance of the lining system. It is important to follow the manufacturer's guidelines for mixing, placing, and curing the monolithic refractory material. Improper installation can lead to reduced lining integrity, decreased thermal conductivity, and compromised structural stability. 4. Bonding and anchoring: Ensuring a strong bond between the monolithic refractory and the substrate is essential for effective lining performance. Proper surface preparation, selection of suitable bonding agents, and appropriate anchoring techniques should be considered to enhance the adhesion and stability of the lining system. 5. Structural design: The structural design of the lining system should be carefully planned to withstand the mechanical stresses and operational conditions. Factors such as load-bearing capacity, thermal shock resistance, and thermal cycling should be taken into consideration during the design phase. Reinforcement materials, such as steel fibers or mesh, may be required to enhance the structural integrity and prevent cracking or spalling. 6. Maintenance and repair: Anticipating the need for maintenance and repair is crucial for the longevity of the lining system. Consideration should be given to access points, inspection ports, and repair techniques. Regular inspections and proactive maintenance can help identify and address any issues before they escalate and lead to major failures. By considering these key factors when designing the lining system with monolithic refractories, one can ensure a well-designed and effective lining that can withstand the harsh conditions and provide long-term performance.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Monolithic Refractories for Iron and Steel Industry:Corundum Castable for EAF Roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords