Monolithic Refractories for Iron and Steel Industry - Fireclay Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Fireclay Based Mortar for Hot Blast Stove

Made as per international standards, FIREF fireclay based mortar for hot blast stove is known for its low thermal conductivity, high refractoriness, and excellent thermal shock resistance.

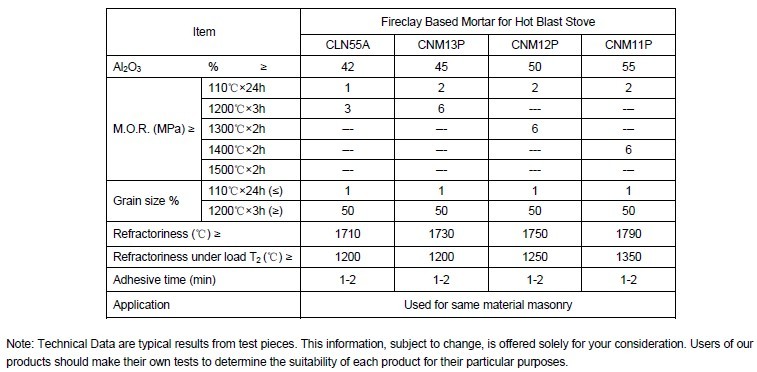

Technical data of Fireclay Based Mortar for Hot Blast Stove

Production line and packing of Fireclay Based Mortar for Hot Blast Stove

Feature of Fireclay Based Mortar for Hot Blast Stove

Low thermal conductivity

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Application of Fireclay Based Mortar for Hot Blast Stove

FIREF fireclay based mortar for hot blast stove can be used together with the same material fireclay bricks.

Production Flow of Fireclay Based Mortar for Hot Blast Stove

- Q: How do monolithic refractories withstand high temperatures in iron and steel production?

- Monolithic refractories are specially designed to withstand the high temperatures encountered in iron and steel production. These refractories are made from a single piece or a single material, unlike traditional brick refractories that are made by laying bricks one by one. The ability of monolithic refractories to withstand high temperatures is due to their unique composition and structure. They are made from high-quality raw materials such as alumina, magnesia, silica, and carbon, which have high melting points and excellent heat resistance. The monolithic refractory is typically mixed with a binder, such as clay or cement, to give it shape and strength. This binder helps to hold the refractory particles together and provides the necessary structure to withstand thermal stresses. Additionally, various additives and additives can be included in the mix to further enhance the refractory properties. During iron and steel production, the monolithic refractories are exposed to extreme temperatures, rapid heating, and cooling cycles, as well as chemical reactions with molten metals and slag. However, the unique composition and structure of monolithic refractories enable them to endure these harsh conditions. The high melting point materials used in monolithic refractories prevent them from melting or deforming under the intense heat of iron and steel production. These materials have excellent thermal conductivity, allowing them to effectively transfer heat away from the hot surfaces, thus preventing overheating and damage. Furthermore, the binders and additives in monolithic refractories help to increase their resistance to thermal shock, which occurs when there is a rapid change in temperature. This resistance is crucial in iron and steel production since the refractories are frequently exposed to extreme temperature differentials. Lastly, the monolithic nature of these refractories eliminates the joints and gaps found in traditional brick refractories. The absence of joints minimizes the risk of heat leakage and infiltration of molten metal or slag, ensuring a more efficient and durable lining. In conclusion, monolithic refractories are specifically designed to withstand the high temperatures encountered in iron and steel production. Their composition, structure, and unique properties enable them to endure extreme heat, rapid temperature changes, chemical reactions, and thermal stresses, making them essential components in the manufacturing of iron and steel.

- Q: How do monolithic refractories prevent thermal radiation in the iron and steel industry?

- Monolithic refractories play a crucial role in preventing thermal radiation in the iron and steel industry. Thermal radiation refers to the transfer of heat energy through electromagnetic waves, and it can be a significant challenge in this industry due to the high temperatures involved. Monolithic refractories, which are single-piece refractory materials, are designed to have excellent thermal insulation properties. They have low thermal conductivity, which means they are not good conductors of heat. This property allows them to act as a barrier against thermal radiation. When used in the iron and steel industry, monolithic refractories are typically applied as linings in furnaces, ladles, and other equipment that are exposed to extremely high temperatures. These linings serve as a protective layer, preventing the heat from escaping and reducing the amount of thermal radiation emitted. Additionally, monolithic refractories have high emissivity, which refers to their ability to absorb and re-emit thermal radiation. This property allows them to effectively capture and contain the heat within the equipment, minimizing the amount of radiation that escapes into the surroundings. By preventing thermal radiation, monolithic refractories help to maintain the desired temperatures within the iron and steel production process. This is crucial for achieving efficient and controlled operations, as well as ensuring the quality of the final products. Furthermore, the use of monolithic refractories in the iron and steel industry also contributes to energy savings. By reducing the heat loss through thermal radiation, less energy is required to maintain the desired temperatures, resulting in lower energy consumption and cost savings. In conclusion, monolithic refractories are essential in preventing thermal radiation in the iron and steel industry. Their excellent thermal insulation properties, low thermal conductivity, and high emissivity make them effective barriers against heat transfer through radiation. By minimizing heat loss and ensuring controlled temperatures, monolithic refractories contribute to efficient operations, high-quality products, and energy savings.

- Q: What are the considerations for repairing and relining monolithic refractories?

- When repairing and relining monolithic refractories, there are several key considerations that need to be taken into account. First and foremost, it is crucial to assess the extent of the damage or deterioration in order to determine the appropriate repair method. Factors such as the type of refractory material, the operating conditions, and the expected service life must be considered. Additionally, it is essential to select the right refractory material for the repair or relining process. This involves evaluating the temperature range, chemical resistance, thermal conductivity, and mechanical properties of the refractory material to ensure it is compatible with the specific application. Another important consideration is the proper preparation of the surface before applying the repair material. This may involve removing any loose or damaged refractory, cleaning the surface thoroughly, and creating a suitable bonding surface to ensure optimal adhesion. Furthermore, the application technique and curing process of the repair material should be carefully followed to achieve the desired performance and durability. This may involve proper mixing, application thickness, drying time, and temperature control. Lastly, it is crucial to conduct regular inspections and maintenance to identify any signs of deterioration or damage early on. This proactive approach will help prevent major repairs or relining in the future and prolong the overall lifespan of the monolithic refractories.

- Q: How do monolithic refractories resist thermal shock in the iron and steel industry?

- Monolithic refractories are designed specifically to withstand thermal shock in the iron and steel industry, achieved primarily through their unique composition and structure. To begin, high-quality raw materials, such as alumina, magnesia, and silica, are used to create monolithic refractories. These materials are chosen carefully for their excellent thermal properties, including a high melting point, low thermal conductivity, and favorable thermal expansion characteristics. The manufacturing process of monolithic refractories involves precise control over the distribution of grain sizes and the addition of bonding agents. This results in a dense and uniform structure, enhancing their resilience against thermal shock. The bonding agents also play a crucial role in strengthening and maintaining the integrity of the refractories. Furthermore, additives are often incorporated into monolithic refractories to increase their resistance to thermal shock. These additives, such as zirconia, silicon carbide, or graphite, enhance the refractories' ability to endure rapid temperature changes. Moreover, monolithic refractories are designed with low porosity to minimize the penetration of molten metal or slag into the material. This helps prevent the formation of cracks and spalling, which can occur due to thermal shock. In addition, monolithic refractories are commonly applied as a lining or coating on furnace surfaces or other equipment. This creates a protective barrier, reducing direct exposure to extreme temperatures and thermal cycling. Overall, the combination of high-quality raw materials, meticulous manufacturing processes, additives, low porosity, and appropriate application techniques make monolithic refractories highly resistant to thermal shock in the iron and steel industry. They can endure rapid temperature changes, prevent cracks, and maintain their structural integrity, ensuring the reliable and efficient operation of furnaces and other equipment in this demanding industry.

- Q: What are the key properties of gunning mixes used for monolithic refractory repairs?

- The key properties of gunning mixes used for monolithic refractory repairs are high strength, good adhesion, excellent workability, and high resistance to thermal shock and abrasion. These properties ensure that the gunning mix can withstand the intense heat and harsh conditions of refractory applications, providing a durable and long-lasting repair solution.

- Q: How do monolithic refractories improve the performance and efficiency of iron and steel production?

- Improved performance and efficiency in iron and steel production are achieved through the utilization of monolithic refractories. These specialized materials are designed to withstand extreme temperatures, chemical reactions, and mechanical stresses, making them ideal for high-temperature industrial processes. A key contribution of monolithic refractories is their ability to provide a protective lining for furnaces, kilns, and other equipment used in iron and steel production. Their superior heat resistance ensures that the underlying structure is shielded from the intense heat, preventing any detrimental effects on the equipment. This results in reduced downtime, extended service life, and ultimately, enhanced overall efficiency. Furthermore, monolithic refractories play a crucial role in improving thermal efficiency during the production process. By minimizing heat losses, these materials help maintain a stable and uniform temperature distribution, thereby enhancing the energy efficiency of the system. Precise temperature control is of utmost importance in iron and steel production to achieve the desired metallurgical properties of the final product. Additionally, monolithic refractories exhibit excellent resistance to chemical corrosion, erosion, and slag attacks. They act as a barrier between the molten metal and the refractory lining, preventing unwanted reactions and material degradation. This preserves the integrity of the furnace lining, reducing the need for frequent repairs or replacements. Consequently, it leads to increased productivity and long-term cost savings. Moreover, the ease with which monolithic refractories can be shaped, repaired, or replaced is another advantage. Unlike traditional brick refractories, which require labor-intensive and time-consuming installation, monolithic refractories offer a more flexible and efficient application. Their flexible nature allows for easy repair of damaged areas, minimizing downtime and ensuring uninterrupted production. In summary, the utilization of monolithic refractories significantly enhances the performance and efficiency of iron and steel production. These materials provide a protective lining, improve thermal efficiency, resist chemical corrosion, and offer easy installation and repair options. By optimizing the production process, monolithic refractories contribute to higher productivity, reduced downtime, and increased cost-effectiveness in the iron and steel industry.

- Q: How do monolithic refractories enhance the performance of ladle and tundish covers?

- Monolithic refractories play a crucial role in enhancing the performance of ladle and tundish covers in several ways. Firstly, monolithic refractories offer excellent thermal insulation properties. Ladles and tundishes are exposed to extremely high temperatures during the steelmaking process. By using monolithic refractories, the covers can effectively trap and retain heat, preventing excessive heat loss. This insulation capability not only helps to maintain the desired temperature of the molten steel but also reduces the energy consumption required for heating. Secondly, monolithic refractories provide superior resistance to thermal shock. When ladles and tundishes are filled with molten steel, there is a rapid and drastic temperature change in the refractory lining. This thermal shock can cause cracking and spalling of the lining, compromising its integrity. However, monolithic refractories possess high thermal shock resistance, allowing them to withstand these sudden temperature fluctuations without significant damage. This ensures the longevity and durability of the ladle and tundish covers. Furthermore, monolithic refractories exhibit excellent corrosion resistance. The molten steel and other aggressive chemicals present in the ladles and tundishes can erode the refractory lining over time. However, monolithic refractories are specifically designed to withstand these corrosive environments, protecting the covers from chemical attack and erosion. This resistance to corrosion enhances the lifespan of the ladle and tundish covers, reducing the need for frequent replacements and associated downtime. Additionally, monolithic refractories offer good mechanical strength and stability. The ladles and tundishes undergo various mechanical stresses, including the weight of the molten steel, thermal expansions, and vibrations. The use of monolithic refractories provides the necessary strength and stability to withstand these mechanical forces, preventing structural failures and maintaining the integrity of the covers. In summary, monolithic refractories enhance the performance of ladle and tundish covers by providing excellent thermal insulation, resistance to thermal shock and corrosion, and sufficient mechanical strength. These properties ensure efficient steelmaking processes, reduce maintenance costs, and prolong the lifespan of ladles and tundishes.

- Q: How do monolithic refractories contribute to the quality of iron and steel products?

- Enhancing the quality of iron and steel products is a crucial role played by monolithic refractories. These refractories consist of a single, solid structure that grants them high resistance against thermal and mechanical stresses. Their unique properties make them suitable for a range of high-temperature applications in the iron and steel industry. To start with, monolithic refractories excel in thermal insulation, maintaining a consistent temperature within furnaces and kilns. This temperature stability is vital for the proper heat treatment of iron and steel, ensuring ideal metallurgical properties and reducing the risk of defects. By preventing heat loss, monolithic refractories promote efficient energy utilization, resulting in cost savings and environmental benefits. In addition, monolithic refractories demonstrate remarkable endurance in the face of harsh operating conditions. The iron and steel manufacturing process involves extreme temperatures, aggressive chemical environments, and mechanical stresses. Monolithic refractories exhibit exceptional resistance to these conditions, ensuring durability and longevity. Their ability to resist thermal shock prevents cracking or spalling, which can lead to contamination and compromised product quality. Furthermore, monolithic refractories provide excellent corrosion resistance, shielding iron and steel products from chemical reactions with molten metal, slag, and other aggressive substances. This resistance not only preserves the integrity of the refractory lining but also prevents contamination of the metal, resulting in improved product quality. Monolithic refractories also offer flexibility in design and installation. They can be shaped, cast, or gunned into various complex geometries, allowing for customization based on the specific requirements of the iron and steel production process. This versatility ensures optimal lining performance, maximizing efficiency and product quality. In conclusion, monolithic refractories significantly contribute to the quality of iron and steel products. Their thermal insulation properties, resistance to harsh operating conditions, corrosion resistance, and design flexibility all play a vital role. By providing a reliable and durable lining in high-temperature applications, monolithic refractories help guarantee consistent and high-quality output in the iron and steel industry.

- Q: How do monolithic refractories enhance the performance of ladle and tundish purging systems?

- The performance of ladle and tundish purging systems is greatly improved by the use of monolithic refractories. These refractories offer various advantages in enhancing the efficiency and effectiveness of the purging process. To begin with, the thermal insulation properties of monolithic refractories are exceptional. When impurities and gases need to be eliminated from molten metal, high temperatures are necessary. By utilizing monolithic refractories, heat loss is minimized, and the desired temperature within the system is maintained. This ensures that the purging process is carried out effectively and efficiently. Furthermore, monolithic refractories possess superior resistance to erosion and corrosion. The molten metal and purging gases can be corrosive and abrasive, making it essential for the lining to withstand such harsh conditions. Monolithic refractories are specifically designed to endure these circumstances, preventing erosion and corrosion. This contributes to the longevity of the ladle and tundish purging systems, reducing the need for frequent repairs or replacements. Additionally, monolithic refractories provide remarkable strength and stability. As molten metal and purging gases move within the system, significant mechanical stresses are experienced. The use of monolithic refractories ensures that the lining remains structurally sound, preventing any deformation or failure under these conditions. This guarantees smooth and uninterrupted purging operations, thus enhancing the overall performance of the system. Moreover, the installation and maintenance of monolithic refractories are straightforward. Unlike traditional brick and mortar refractories, monolithic refractories can be easily applied as a single, uniform layer. This simplifies the installation process and reduces the time and effort required for maintenance. Any necessary repairs or replacements can be conducted more efficiently, resulting in minimal downtime and maximum productivity for the ladle and tundish purging systems. In conclusion, monolithic refractories significantly improve the performance of ladle and tundish purging systems by providing excellent thermal insulation, erosion and corrosion resistance, strength and stability, as well as ease of installation and maintenance. These properties contribute to the efficient and effective removal of impurities and gases from molten metal, ensuring high-quality output and optimizing the overall productivity of the purging process.

- Q: How do monolithic refractories contribute to the reduction of heat loss in ladles and tundishes?

- The use of monolithic refractories is crucial in reducing heat loss in ladles and tundishes. These refractories are designed to have excellent thermal insulation properties, which effectively minimize the transfer of heat from the molten metal to the surrounding environment. Conduction is a key factor that contributes to heat loss in ladles and tundishes. It occurs when heat is transferred through direct contact with the refractory lining. However, monolithic refractories are specifically engineered to have low thermal conductivity, making them efficient in reducing heat transfer through conduction. This, in turn, helps to maintain the desired temperature of the molten metal for longer periods, resulting in lower energy consumption and improved process efficiency. Additionally, monolithic refractories also aid in reducing heat loss through radiation. They have high emissivity, meaning they emit a significant amount of thermal radiation. This emitted radiation creates a heat shield around the molten metal, preventing heat loss to the surroundings. By effectively trapping the radiant heat, monolithic refractories contribute to maintaining the desired temperature in ladles and tundishes, minimizing heat loss. Apart from their thermal insulation properties, monolithic refractories also offer excellent resistance to thermal shock and mechanical stress. This ensures that they remain intact and functional even in the harsh operating conditions of ladles and tundishes. The durability of these refractories further contributes to the reduction of heat loss by preventing any cracks or gaps in the refractory lining that could facilitate heat transfer. To summarize, monolithic refractories play a significant role in reducing heat loss in ladles and tundishes by minimizing heat transfer through conduction and radiation. Their thermal insulation properties, combined with their resistance to thermal shock and mechanical stress, help to maintain the desired temperature of the molten metal, improve energy efficiency, and enhance the overall performance of these metallurgical vessels.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Fireclay Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords