interior ceramic wall tiles for Yemen market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

interior ceramic wall tiles for Yemen market

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

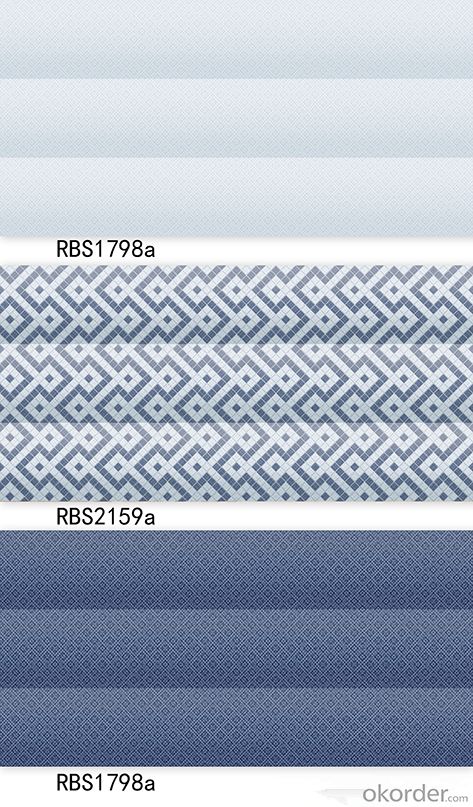

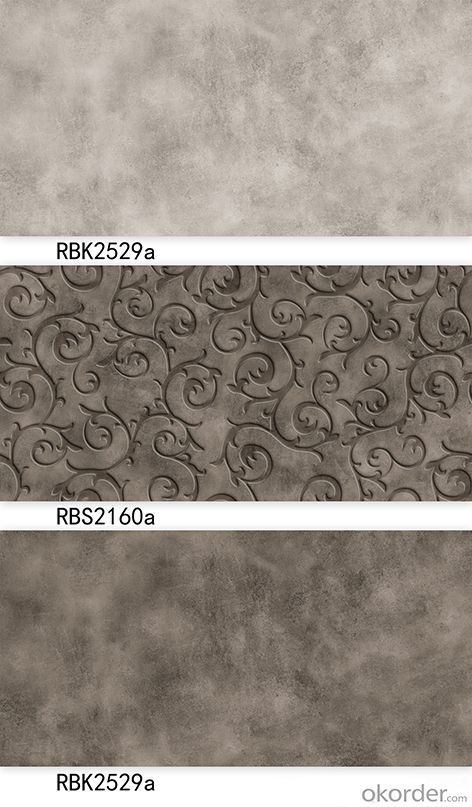

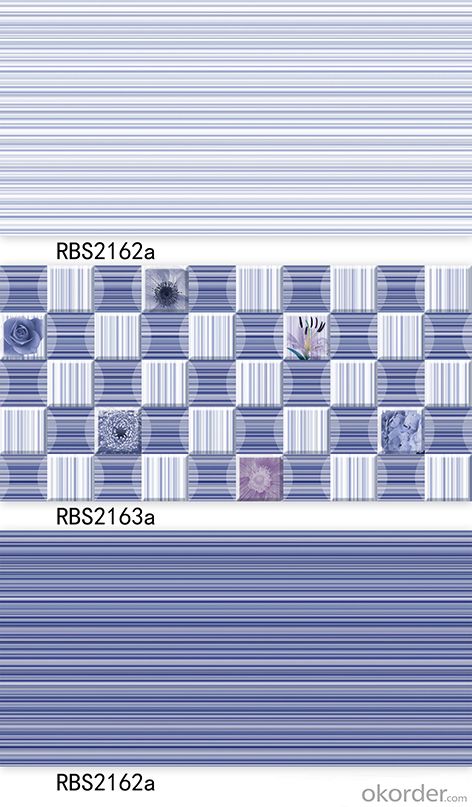

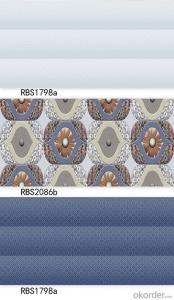

Product effect:

Company information:

Our company founded in 2004,is a professional manufacturer of all types of ceramic tiles and porcelain tiles,covering an area of 180,000 square meters.Currently we have over 1000 staff,including 72 research & development talents with years'experience in this field.

With international advanced machines imported from Italy and Spain, we can provide tiles with superior quality standard. Our company obtained the ISO9001 Quality Management System Certificate,thereby ensuring that we can supply clients with a significant quality guarantee.

Moreover,we greatly pay attention to constant technical innovation.Over the past few years,we have developed a wide range of wall tiles and floor tiles.These products are available in 300*600mm,400*800mm,300*900mm,600*600mm ,800*800mmm ...

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

- Q: What are the differences and which one is better?

- In general terms Engineered hardwood fooring is pretty much better compared to 100% hardwood floors. 1. Stability: Instability of solid wood is mainly affected by moisture and heat, wherein it could warp, swell and split apart. none of these problems is present in the engineered wood. Therefore these said set back experienced by building contractors were very much taken cared off by manufacturers of this said simulated wood. 2. Aesthetics: Engineered wood uses also real wood veneers and produces same effect than real hard wood with a very hard finish designed for heavy traffic,Personal opinion: True hard wood is very expensive and requires skilled work in order to attain a desired effect. BUT......... If you have money to burn ... Use true solid wood wherein you could see a big difference in ELEGANCE and BEAUTY of a real wood.Much more joints could be SEAMLESS compared to engineered wood because it comes in panels with the tongue and groove connection. Have a nice day, Borges (Philippines)

- Q: What kind of wood flooring?

- Toothed oakAdvantages: hard material, thick structure, high strength, color, good finish, easy drying.Disadvantages: difficult processing, poor bonding, easy cracking.

- Q: And where's the best place to shop for either hardwood floor in Toronto?

- All depends on the exact installation method your doing. Not all engineered wood is of the click and lock variety and can be stapled ( special air driven stapler that you can rent) or glued down. Solid wood needs to also be nailed or stapled to install. Solid wood cannot be glued down. So choose your installation method. But between the 2, I prefer engineered wood. Fits together easier, lighter weight and much faster if your stapling it down. Gluing is easy but messy. But your solid wood will be a bit better in the long haul. As to were to get it, I prefer the small flooring stores to get more personalized service. You will pay less at times in the big box stores, but not always, check both places. Any questions you can e mail me through my avatar. GL

- Q: hardwood flooring is not so popular in my country but I like it , I went to store today and found 3 strip engineered wood flooring ..will it look as good as the plank wood flooring ? or it'll look cheaper ?

- Although some of these look better than others , you ll be able to tell it comes in a 3 strip pc. You ll be able to see the seams a bit. Some do go together better than others and are not as noticeable but again some look real bad. The over all top look plays a part in the final look also. But the bottom line is that it won t look quite as good as the single stripe. GL

- Q: Can engineered wood flooring be installed on vinyl flooring?I'm in the middle of home improvement project and have decided to lay some engineered wood flooring for my kitchen. The particular brand that I've bought requires glue-down installation.The problem is, there's vinyl flooring that's been laid with cutback and it's not going to come up without a significant amount of work and then re-preparation of the sub flooring. I've been to the local home improvement center several times and can't really get a straight answer as to if this is possible. I've searched the Internet and its about 50-50 yes and no. I'd really like anybody's input into my situation, as I am under a little bit of a time constraint to finish the project as this is my new house and I've got to move out of my old house in in a week.Thanks in advance to your answers!

- The vinyl floor is likely glued down to 1/4 inch underlayment (luan). You could pull it all up and put down new underlayment in a couple of hours. Or, if you're not worried about the height of the new floor, you could put the new underlayment on top of the vinyl floor. I've been a carpenter for 18 years and before that I laid floor for 2 years. I've never seen anyone glue any kind of floor to an old vinyl floor. I don't think it would be a good idea. If you do decide to give it a try, you may want to go over the vinyl with a disc sander to help the glue bond better.

- Q: Good evening. I'm currently having a contractor install engineered hardwood on my steps. I have 3 planks that are 3/8 think. He is in the middle of construction now.

- I would have the installer remove the rabbit edge and shim up the flooring to the nosing, so they are at the same height. Serious problem for kids, toddlers and high heel shoes. Plus it's very uncomfortable to walk up and down the stairs on an uneven surface. Carrying anything heavy up and down these treads can become a major problem, also. How wide are these treads? Stair nosing is probably about 3 inch wide, which leaves you about 7-8 inch of surface to get your foot on. Factor in the overhang and you really only have about 5-6 inch of foot space, clearance. Unless you have small feet, I wouldn't install this type of set-up on stairs. Landings are exceptable, because it has a bigger surface, following the nosing. The trip can either be caused by the uneven surface or the overhang. Why not just install prefinished solid treads? Just some food for thoughts.

- Q: Some people say that the following floor is damp, there are above the floor below the film cover, gas out, will make the floor below the drum, which led to the floor above the drum, this statement is not it? My home is not a floor, the floor will get damp? Will there be any problem? Please experienced friend told me, what should I do. Sincere thanks!

- Unwanted。Prior to the solid wood floor keel generally leveling, then the surface of the solid wood floor has been very flat, and directly paved the whole good, there is no sound.But you'd better check the degree of decay. There is a lot of noise on the floor.If you want to shop floor stability, direct shop in the original solid wood floor is not the best choice

- Q: I plan to take away the carpet in my basement, and install some other type of flooring. A friend recommended the engineering hardwood flooring. Yet I heard that a little moisture would be disastrous for this type of flooring. Is there a better option out there?

- you need to do a moisture test on your floor first to see if it is feasible first you get a gallon Ziploc and tape (duct tape) it to an exposed area of concrete leave it for 24 hrs if moisture collects on the bag you need another flooring. you could go with laminate and get a moisture barrier padding to go under it, or there is a flexible floating PVC flooring out now the more pricier ones have texture that feels like wood and looks so real i have seen people actually touch it before they believed it wasn't

- Q: What are the reasons for deformation of solid wood flooring?

- Arch is mainly because the floor is installed, the floor and the wall spacing is too small. When the floor when the heat or moisture swelling, there is not enough space, so the center of the floor arch up

- Q: Hi, We are planning to get Engineered Hardwood in our home (Family and bedrooms). I was wondering if glue or nails is the way to go. Both areas have sub floors. I have read that Engg Hardwood floors may be more noisy. How can we prevent that.Thank you

- Before putting the floor down go over the sub floor and nail down any loose boards or anywhere it squeaks. There is a special padding that goes down then you install the new floor on top. You do not nail or glue it as it needs to float a bit.

Send your message to us

interior ceramic wall tiles for Yemen market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches