Yongsen Grade A Pure Africa Teak Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 22000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Tree bark

: thick 1.25px, smooth, soft, easy to break and block off. Skin yellow to grayish brown, with irregular cracks, brittle flaking. Endothelial brown, pinch easily into downy fibers.

Cross section

Heartwood clear. Heartwood when fresh yellow brown, dark brown long home atmosphere transfer. Sapwood width of about 62.5px, narrow, shallow color. Growth wheel is not obvious.

Wood properties

: wood is diffuse porous wood, sapwood narrow, width 1.5-62.5px, heartwood yellowish brown to dark brown and sapwood and obvious difference; growth ring was not obvious;

Wood has a luster, no special smell; texture until slightly staggered, the structure is very fine and uniform; the durability of wood is high, not easy to rot and insects; dry shrinkage, dry, good stability. The strength and mechanical parameters of wood are higher. Good processing performance, surface processing, paint, adhesive, etc. turning performance is good. Bending performance, grip strength. Contact with the black metal easy to rust. Air dry density 0.70-0.86g/cm3.

2、Product Characteristics

1, naturally contain heavy oil, moisture, pest control, anti termite. Teak cut down a month later, due to being changed to nutrition, mothproof effect. Also is especially resistant, teak Millennium does not rot proof.

2, micro pinhole solid structure, made of teak wood floor has both strength and toughness, good stability, normal hardwood floor installed within two years winter there will be expansion is bigger, gap up to 3 to 4 mm; and the summer and systolic bulge, easy to have the sound. Teak wood floor stability.

3, the classic color, golden brown to deep brown, soft Moxian, beautiful oil shadow, form varied texture, atmospheric, elegant.

4, teak unique mellow, insect prevention termite, anti acid, alkali, corrosion resistance. The unique flavor of the old people's brain nerve has a soothing effect, promote sleep.

5, long time, with more beautiful color.

3、Parameter

Material: Teak

Style: Modern

Standard: ISO90001

Applicable scope: bedroom

Pattern: Wood

Special purpose wear

Plate finish: good

Surface shape: paint:

Residual depression: no formaldehyde release amount: E1

Resistance: good

Wear layer thickness: 3cm

Abrasion resistance: good

Fading (stage): 1

Floor thickness: 18mm

Whether to refer to the floor: no

Color: yellow

Specifications: 910*122*18

4、Reference pictures

- Q: Hi, we recently had some engineered hardwood installed in our new home. We currently have a dining table and chairs that have the roll legs on the chairs. This concerns me, do we have to be worried about making marks on our beautiful new floors? It is a floating floor system, we have heating pads under them. Thanks!!

- First, it depends on the sealant and how many coats were put on. This would protect the floor, but over time would need to be re-sealed. Can you let me know if this was sealed, with what sealant if you know and how many coats.

- Q: hardwood flooring is not so popular in my country but I like it , I went to store today and found 3 strip engineered wood flooring ..will it look as good as the plank wood flooring ? or it'll look cheaper ?

- I personally like the single plank much better. You can always tell that it is 3 strip after awhile and in my opinion it does look cheap

- Q: Multilayer solid wood floors and wood floors which good

- The standard of solid wood flooring is GB/T15306-2001. Since the implementation of the standard since May 1, 2002, the original 94 standard was replaced. The new national standard has made the important revision and the supplement to the old national standard. The main content is to modify some of the size and content of the supplement, the application of the specification of the tree species and the requirements of the paint plate. At the same time, the impact toughness and abrasion resistance of the wood are eliminated. In the past the market once chaos marked name, name and fake hybrid between strange and eccentric, and what Watkins grapefruit, Jinbuhuan, rich wood, so that customers do not know true and false, good or bad. Therefore, the new standards must be strictly nominal, and in the form of appendix

- Q: When removing the tack strips from our concrete subfloor, little depressions in the concrete were left behind along the edges of the walls. Is it necessary to fill those in with a self leveling compound, or can I just install the engineered hardwood over these areas?

- I had the exact same question when I replaced all the linoleum in my house with tile. My foyer already had tile and it had the installation you refer to. I wanted the same throughout and found an extremely helpful associate at Home Depot. The piece of hardware is called a Z strip. You lay it on the subfloor and nail or screw down a regular tack strip on top of it leaving a narrow gap maybe 1/4 inch between in your case the wood flooring and the top edge of the z strip. Next pull the carpet as tight as possible across the tack strip and tuck under the z strip. I then used a 4 masonry chisel to crimp the z strip down which pins the carpet between it and the subfloor. I apologize for such a long winded answer! The Z strips can be bought at either Lowes or Home Depot and are usually 4 ft long and made out of aluminum and cost about 70-80 cents a piece. The associates at either store could walk you through the installation and I am sure it would make more sense than reading it.

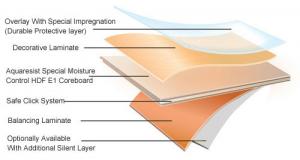

- Q: Difference between engineered wood flooring and solid wood flooring?

- The engineered flooring is less likely to expand or contract than solid wood so it will be more stable.

- Q: What are the major differences between solid hardwood flooring & engineered hardwood flooring? Also, what is the best to use in high traffic areas and non-high traffic areas; like the living room or dinning room?

- Solid hardwood is a better product. Laminate/engineered flooring was a product devised as a way to get a hardwood look at about 50% of the cost. Hardwood is thicker. The product used to be solid oak 3/4 thick (either unfinished or prefinished). It evolved to be applied to concrete floors which comes at 3/8thick. It has since been made from plywood with a veneer finish. This came about do to solid wood cupping up on the ends (where the tongue and groove meet). Now solid 3/4 harwood is seldom used. Most hardwood is a veneer finish at 3/8 to 5/8 and is installed with a locking system (the same as the engineered flooring) or by an adhesive (hardwood glue). the thicker the more expensive, and typically better. The solid wood look is a much better look then laminate and is one of the best features for resale of a home. The surface finish is a little less durable then the laminate flooring. If you damage hardwood and need to replace pieces, hardwood can be replaced fairly easily, whereas laminate is a nightmare (if you replace it properly). You are removing all the existing until you get to the damaged piece and then relaying it. As far as traffic areas, I suggest this, If you have either by an exterior door place a small throw rug down. Either product will not last if it is exposed to moisture/water on the surface and getting into the seams/joints. I also suggest not putting it in what are called wet areas, kitchen, bathrooms because of that. Laminate cleans and maintains easier. Laminate will wear better if you have small children, and again it is about 1/2 the cost. There is no real answer as to what is better. It depends on your situation. Do you want the luxurious look of hardwood or the harwood look at a cheaper price. Your call. I hope this helps you out, and good luck

- Q: which holds up better engineered hardwood floors or solid hardwood floors when you have large dogs?

- Personaly i would go with solid hardwood, only because you can sand them down over time and refinish them. But if you keep your dogs nails trimmed ( any pet store can teach you how) then you shouldn't have trouble with either. But have fun with all the hair your gonna find.

- Q: I plan to take away the carpet in my basement, and install some other type of flooring. A friend recommended the engineering hardwood flooring. Yet I heard that a little moisture would be disastrous for this type of flooring. Is there a better option out there?

- If your basement is properly sealed against moisture and you don't forsee any flooding issues from water heaters or bathroom, then it would be fine. We were looking at a stone tiling instead.

- Q: What are the types of solid wood flooring on the market?

- Solid wood composite floorSolid wood flooring is a general term, in fact, it can be divided into multi-layer solid wood composite floor, three floors of parquet. The characteristics of this kind of floor: good dimensional stability.

- Q: House to be renovated headache for the choice of the floor, wooden floor appearance, but it will also decay, deformation, anti termite; and there is no tile problem, but now many people use wood floor, people really do not know how to choose? Do you have any friends who can give professional advice?

- Indoor light, the light can be considered a strong reflection of the wooden floor, the light can be considered shallow color tiles.Decorative:Combined with the living room walls, ceilings, furniture overall consideration. For example, the walls of the wood structure is more, and are wood type paste, or furniture style classic, with the color of the floor will look more harmonious. For example, if it is hard line style, or black and white color to the main, can be considered with tiles, etc..

Send your message to us

Yongsen Grade A Pure Africa Teak Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 22000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords