HDF Laminated Wooden Floor 8mm High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

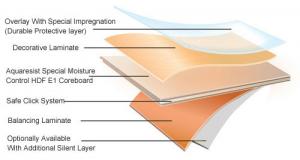

HDF Laminated Wooden Floor 8mm High Quality

Products Specification

We can supply HDF laminated flooring

With thickness 6mm/7mm/8mm/11mm/12mm

With length and width 808*148mm/810*150mm/1215*195mm/1218*198mm/1219*199mm,

With wear resistance from AC1-AC5

With square edge, V-groove, and mouled U-groove

With small/middle embossed surface,silk surface,crystal surface,piano painted surface,synchronized surface and hand scraped surface.

Technology Specification

Performance | Unit | Thickness(mm) |

6/7/8/11/12 | ||

Density | Kg/m3≥ | 800-900kgs/cbm |

Internal bond | Mpa≥ | 1.4 |

Internal density tolerance | ±% | 4.0 |

Bending strength | Mpa≥ | 40 |

Modules of elasticity | Mpa≥ | 3500 |

Thickness swelling | %≤ | 8.0 |

Moisture content | % | 4.0-7.5 |

Surface bond | Mpa≥ | 1.2 |

Formaldehyde release | E0≤0.5mg/L,E1≤9mg/100g,E2≤20mg/100g | |

Test Standard | GB/T17657-1999 JIS A1460 |

Our Service

1.Free samples in each container

2.Free new design products in each container

3.Make samples according to partner’s request

4.Make selling plan in your market together

5.Visit your company when there is a chance

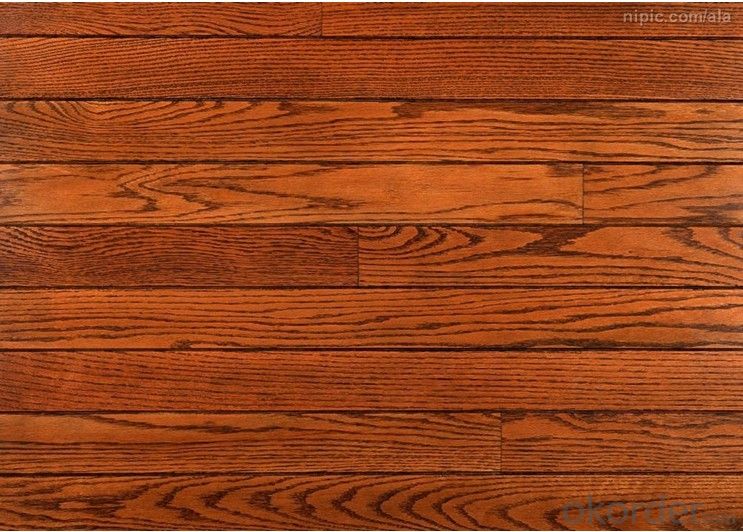

Picture

- Q: I would like to ask wood floors and composite floors which good?

- So I suggest you go to the formal decoration market, get the floor, see is not the real wood. Now the level of fraud is very high, however, a simple look from the side, you can see it. Or secretly with a nail with a wood, if it is false, on the leakage level.

- Q: I have a beautiful engineered hardwood floor in my home but it is getting pretty dirty. Do I need to do anything special when I clean it? Can I use Pine-sol?

- Try to sweep the floors every 2 to 3 days. Vacuum the floor using a soft brush vacuum attachment about once a week. Use a slightly damp mop if the floor is heavily soiled and in need of some extra attention. Ring out the mop well, until it is almost dry. If you feel the need to use cleaning solution on the floor, use one approved by the floor manufacturer. Place area rugs and carpet runners in high traffic areas to protect the floor. Clean underneath them often so that dirt does not filter through the rug and onto the floor. It is also wise to put a heavy mat just outside and inside the door to catch as much dirt as possible. Clean up any liquid spills right away and be sure the floor is completely dry. Liquid is hardwood flooring's biggest enemy.

- Q: How to install a solid wood floor

- The construction shall be dampproof and insect pest control treatment, first sprinkle powder, with moisture-proof paper (film). Waterproof paper (film) to be stacked above 20cm, and shall be laid above foundation 10cm.

- Q: Shop floor bedroom to shop wood flooring, solid wood flooring but the feeling is very delicate, do not wear, even with a few years spent, how to do?

- Traditional solid wood flooring, the surface is only covered with a layer of paint, wear resistance is indeed worse than the composite floor. But now a lot of brands to adopt new technology, 000 diamond surface titanium paint such as Baer, the floor of the Bordeaux rhyme with UV piano paint technology, greatly improve the wear resistance of solid wood flooring

- Q: hi,we bought this very nice red oak wood flooring. I think its some kind of engineered flooring. Anyway my question is do I need a moister barrier in my 2nd story rooms? The house was built in 2004 ( in case that matters) I know I have to put a foam down to reduce the noise but I don't think that the 2nd story has any moister.Oh by the way we are in south California so it is warm and dry most of the year.Thanks for all you help

- Moisture Barrier For Hardwood Floors

- Q: Solid wood composite wood floors, or pure wood floor, which is more environmentally friendly economy?

- Solid wood is certainly good, because the solid wood flooring is cut with natural wood, not the use of adhesives, so that more environmentally friendly.

- Q: how to install wood floors?

- Your question cannot be answered in detail as you ask it. First of all, what kind of wood floors are you taking about, 3/4 hardwood, 3/8 hardwood, laminate, engineered flooring. . .what? Second, what are you installing the floor over, wood or concrete? That will determine what kind of flooring you can use. Finally, there are certain ground rules that are common to most wood flooring. First, make sure the subfloor is level. If you have peaks and valleys in your subfloor, it will stress the flooring and cause premature failure. Know what kind of moisture barrier you need. This will depend on whether the flooring is in a dry (living room, etc.) environment or a wet one like a kitchen or bathroom. Pay attention to the maximum height of your flooring and use the underlayment thickness that will get you to the right height. Keep flooring about 1/4 away from walls to allow for flooring expansion and contraction with moisture and temperature. Finally, for wood floors, allow the flooring to come to temperature in the room it will be installed for at least 72 hours. I strongly suggest you do your homework and research what kind of flooring you want, and what will be best for your application. Unless you have the fundamentals down, you are wasting our time with a non-specific question such as yours.

- Q: I have 2 small dogs and one big dog, which one would be the best? do they scratch easy? I defiantly don't want laminate, it looks too cheap.

- They would both scratch the same, the engineered floors have a thin layer of wood, over a cheaper wood, and cannot be sanded and refinished. I would opt for the hardwood, it can be refinshed numerous times. We have red oak in our house, he main part of the house has been refinished once, in 32 years. I use area rugs, where it gets the most wear. Washable ones.

- Q: This has an engineered backing with real oak top about 1/4 thick.

- If you are planning to sand them be careful with the large floor sanders which use a horizontal cylinder as often offered by hire shops. They are OK but can cut very quickly so any hesitation and you could cut through you 1/4 oak. Random orbit sanders are slower but do a better job and produce a flatter surface, in my opinion.

- Q: I'm wanting to put wood floors in and I've noticed that not all allow you to float them. Some have to be glued or nailed? They look the same to me. This is going in over concrete. But why don't all work for floating floors? Whats the diff?

- I would imagine is has to do with expansion and contraction properties of the different types of hardwoods.

Send your message to us

HDF Laminated Wooden Floor 8mm High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches