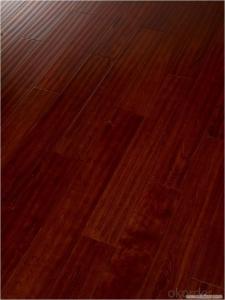

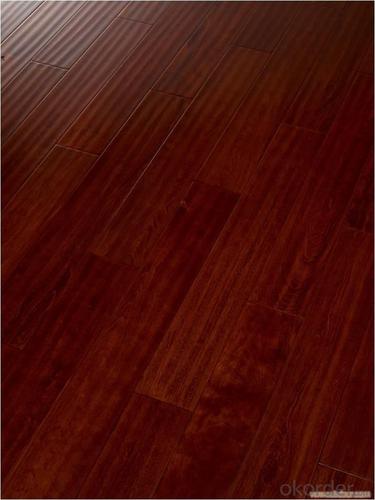

Yongsen Solid wood Floor Of The Disc Beans Red Light A Grade Pure Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Geographical environment and climate characteristics of the material itself has a unique aesthetic and textured, dark stripes and glossy, and sapwood distinguishable. In the structure, the wood is very resistant to decay, and the wear resistance is good, and it has good weather resistance. Air dry density 0.61-0.99g/ cubic centimeters and modified wood drying after yellowish brown or dark brown, hard materials, slightly oily, stability is very good, natural resistance to rot.

2、Characteristic

1.solid wood floor, the solid wood floor, is not easy to deformation, the use of geothermal heating of the user if you must use solid wood floor, then you can use the disc beans solid wood floor.

2. disc beans solid wood floor color, made of dark wood floor is very high, but not suitable for light colored floor users.

3. disc beans solid wood flooring high hardness, impact resistance, good abrasion resistance, and occasionally hit the heavy will not have any trace.

4.Disc beans solid wood floor pattern, and therefore larger, not suitable for the pursuit of the perfect style of the user.

3、Application

Solid wood flooring is the direct processing of wood into the floor. It has the natural development of the wood texture, is a poor conductor of heat, can have the effect of warm in winter and cool in summer, comfortable foot feeling, the safe use of the characteristics is the ideal material for the bedroom, living room, study, ground decoration.

4、Parameter

The water content index refers to the solid wood floor in the sales area or just remove the unopened packaging under the condition of water rate. National standard provisions of the moisture content of solid wood floor indicator for the balance of the 7% to the sales site.

Reflect the paint board surface wear-resisting is solid wood flooring paint surface wear-resisting degree, national standards for superior quality solid wood floor paint board surface abrasion resistance index is less than or equal to 0.08g/100r; first-class product is less than or equal to 0.10g/100r; qualified product is less than or equal to 0.15g/100r.

Reflect the adhesion of the paint to paint the adhesion strength of solid wood flooring, national standard superior quality solid wood floor paint film adhesion index 0 to 1 level; first-class product is less than or equal to 2; qualified product is less than or equal to 3.

Film hardness is a reflection of the strength of the surface film of solid wood flooring, the provisions of national standards of superior quality solid wood floor paint film hardness index for 2h grade; first-class and qualified products is greater than or equal to H.

5、Reference pictures

- Q: Veneer wood floor?It's a dish bean

- And laminate flooring? Solid wood is immune through stickers and molded floor, so expensive. Surface stickers are laminate flooring.

- Q: Some solid wood floor light, which is good, how to separate

- The floor is mainly to see the stability, than the major wood species in the impact resistance wear better, but there are many there will be little paint adhesion, poor toughness (Yi Kailie) etc., and the proportion of small plates most paint with good adhesion and good toughness, but because of low density and fiber hole, shrinkage and swelling rate some big.

- Q: Hi, we recently had some engineered hardwood installed in our new home. We currently have a dining table and chairs that have the roll legs on the chairs. This concerns me, do we have to be worried about making marks on our beautiful new floors? It is a floating floor system, we have heating pads under them. Thanks!!

- Definitely protect the floor. The casters will mar the floor.I like the caster cups with a little patch of carpet on the bottom. This is especially important for an engineered floor, as the wear layer is very thin and often cannot be refinished like a traditional, solid profile floor.

- Q: We had some damage to kitchen floor which homeowners insurance is covering cost to replace. Flooring company just out with samples of engineered hardwood, but after she left I notice it says commercial flooring on the sample board. What is the difference between commercial and residential engineered hardwood? this is Armstrong, Beckford plank.

- Commercial grade means that a particular product was made strong enough to be installed in commercial buildings. Because foot traffic is so much higher in commercial buildings, flooring made for these types of situations needs to be much more durable than hardwood that you would normally install in your home. If you were to install a residential product in a commercial building the warranty would be null and void. You are perfectly fine installing a commercial hardwood in your home. What you should know ,however, is that insurance companies will only give you enough money to replace like-kind and quality That means the adjuster will determine the grade of hardwood you originally had and only give you enough money for the same grade of hardwood.

- Q: Was it as difficult as all the hype ? What was the hardest part?Estimates for having done are 8-10K, just can't pay that.

- It's easier with swift-lock but KM has good answer. Just don't forget to put the vapor barrier. Concrete holds humidity. You don't want to get your floor damp.

- Q: Wooden floor can be installed for a few days to step on, solid wood and composite respectively need to hang a few days? Because of the urgent need to install curtains!!

- No need to wait, after installation, you can walk on the top, for the installation of curtains do not have any effect - the installation of curtains, will not have an impact on the floor.

- Q: what's a good brand for hardwood floor, laminate and engineering wood?

- Bruce is a good brand of flooring products, and they carry solid wood too. They carry a variety of prefinished flooring product, that would save you a lot of time on installation. Pergo is gaining recognition as a laminated floor manufacturer, but honestly, Ive seen other product at Lowe's that was just as good, and cost less...

- Q: I was told a thick layer of polyurethane glue works just as well as cork for sound proofing for hardwood floors on above ground levels.

- Well When choosing between hardwood and engineered wood the biggest thing that you need to considered is the climate area in which you live. Being in Florida (thats where i live) engineered is definately recomended because it is a much more stable product, due to it's resitance to warping and bowing because of its construction. But if a floor is properly installed there should be no difference, unless it is installed over a plywood sub-floor. However if you are considering laminate flooring that will create a hollow sound with a base grade foam/moisture barrier, however there are some upgrades to the underlayment which will give you a more dense sounding floor.

- Q: engineered hardwood flooring = how good?

- It's actually pretty good. The main disadvantage is you cannot sand the wood to refinish. We just installed some over a concrete floor, looks good.

- Q: I am looking for a good quality wood floor that, if its not real wood, it atleast looks like real hardwood. Like all home owners, I would like a flooring that looks great, is durable, easy to clean, and doesn't sound like your walking on plastic when wearing heels. Also important to note; 1) I own a large Husky 2) my home is on a concrete slab 3) I would like to maximize resale of my home. All or any advice is appreciated.... especially if you know of particular brands of good quality. Thank you!

- Engineered hardwood is by far better than laminate. It is stronger and more durable. It is a better quality and will last longer and have a better resale value. Each wood has a hardness value - the harder the better b/c it will less likely to dent.

Send your message to us

Yongsen Solid wood Floor Of The Disc Beans Red Light A Grade Pure Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords