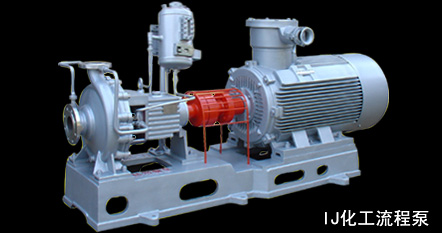

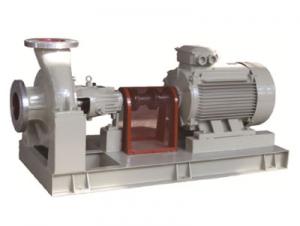

IP Type Petrochemical Process Pump(API610, API682)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Brief Introduction

Conform to API610, API682 standard

Centrifugal volute pump with single stage, single suction and cantilever as well as axial suction, radial discharge design.

Max operating pressure 2.5Mpa

Range of capacity 5~2400m3/h

Total head 5~216m

Range of operating temperature -35~180oC

2. Application

Refineries, petrochemical industry, coal chemical industry

Chemical industry, cyogenic engineering

Water supply factory, sea water desalination factory

Heat supply and air-conditioning system

3. Material

The common materials for wetted parts are 304, 316L, 0Cr25Ni6

4. Rotation direction of pump

It is clockwise viewed from the driver end.

5. FAQ

1 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

2 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

3 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: What is called soft start of water pump?

- Soft start is a form of electronic control, mainly through the soft drive to achieve. Principle: the former contactor is directly started as contactor, first pull in, and the device is started by soft driving. Soft start device start smoothly, starting current is small, control system life is long. Soft start is now in widespread use. But the use of high-power equipment is less, the general current is less than 120A.

- Q: Assuming that my water pump standard flow is 20m3/h, tolerance value requirements is + 8%, then is not traffic 22m3/h is not qualified?

- Only half a year after graduation. Professional stuff is forgotten...I can't help you...

- Q: Two sewage pumps switch from each other, start with float switch control, the first sump, when the water is full, the first start, the second rotation to second units start, so the cycle of alternating

- Can add time delay relay, the key depends on how much time the water is full, if you design is automatic, it is better to use the triode reliable,

- Q: I am trying to replace my old water pump with a new one. I have the quot;special tooland everything but i just cant get the water pump to come loose at all. Any suggestions would be helpful Thanks

- When you mean it wont come loose, do you mean you cant break the bolts loose or is the pump stuck on the motor like glue? If the bolts are stuck, try spray them with penetrating oil and let it work in for about 30 mins. If the pump is stuck, use a narrow putty knif, gently tap in between the pump and the block, and pry it off, then clean the mating surface completely to ensure the new pump seals properly.

- Q: I need to replace a water pump

- Just take off the fan belt, unbolt the water pump and fit the new one. Make sure the gasket area is clean and use a new gasket. If it has the fan on it, take that off first.

- Q: My dad wants to buy a salt water pump for a tiny pool.I'm not sure if it's pointless for the size that the pool is, but it is 12x12x3Is it too small of a pool or are there salt water pumps meant for tiny pools that I could look at?A link to any would be nice. :)Thanks!

- If you live the ocean try the shipyard, or any ,were around dock...or online..

- Q: I just had my water pump replaced and a coolant flush. 35 miles later, my MAL light came on and my mechanic said my thermostat needs replacement. Should this have been done with the water pump work, or could the work have caused the thermostat problem?

- Yes an no. Is it a good idea? Yes. Especially if the vehicle overheated. Is it required? No. It will be extra labor to replace the thermostat. He did not cause the problem but he probably should have recommended it to you. It would have cost you the same extra money then as it did now. Just would have saved you time.

- Q: The car water pump is broken. What are the symptoms?

- China water pump trading network for you to answer: car water leakage symptoms are mainly 1, leakage (water leakage is minor and serious), slight leakage, only in the water pump ventilation holes left on the traces of coolant color. Serious is the direct cause of higher temperature Water Leakage, symptoms of a lack of cooling liquid; 2, the weak ability of circulating pump circulation: if the ability is weak, will appear high temperature phenomenon, especially in the southern summer is more obvious; 3, abnormal sound; if the water pump bearing internal problems, abnormal noises in the belt drive that may be slight, you did not find.

- Q: i am trying to set up a small aqaurium (about 25 gallons) and i am looking for a water pump that will flow water through the aquarium for a period of time and then shut off, and do that like every hour or so. is there such a thing? a water pump with a built in timer so its not running constanly but only every so often? it doesnt need to move alot of water, but i only want it to pump maybe once every hour. thanks for the help

- Don't know why you only want to run periodicly, But at home depot they have timer switches you can plug your pump into it and set the time you want it to go on and off.

- Q: The dealership wants nearly $500. to replace the water pump in our 2002 Tahoe (5.3) it's leaking from the weep hole. I'm somewhat mechanically declined, what precautions will I need to know and any special tools to do the job myself? I've done a few water pumps back in the 1980's that didn't leak Thank you

- i have a 2002 silverado and i had the same problem, here is the deal i am mechanically inclined and the labor on this calls for about 6 to 8 hrs i went to napa and purchased a new water pump not a newly rebuilt one but a new for around 200.00 and let a buddy change mine for 125.00 also go ahead and replace the thermostat while its out because it mounts in the bottom of your water pump they are around 25.00 but anyways i would let someone do it i looked at mine and it covers the whole front of the engine i have replaced numerous water pumps and i didn't like the mess it looked like it would be

Send your message to us

IP Type Petrochemical Process Pump(API610, API682)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords