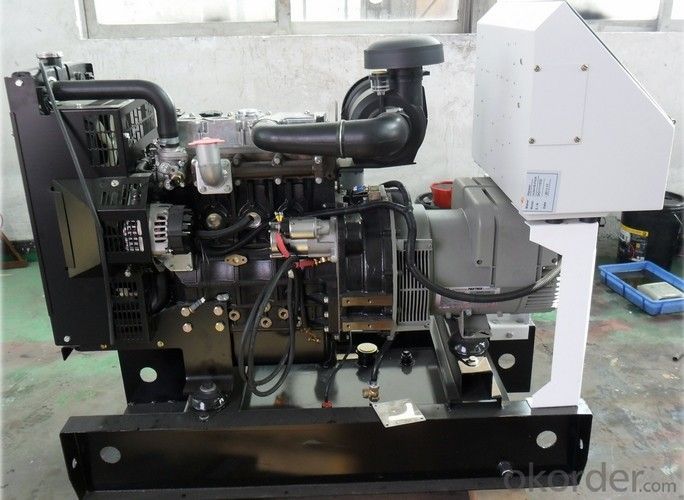

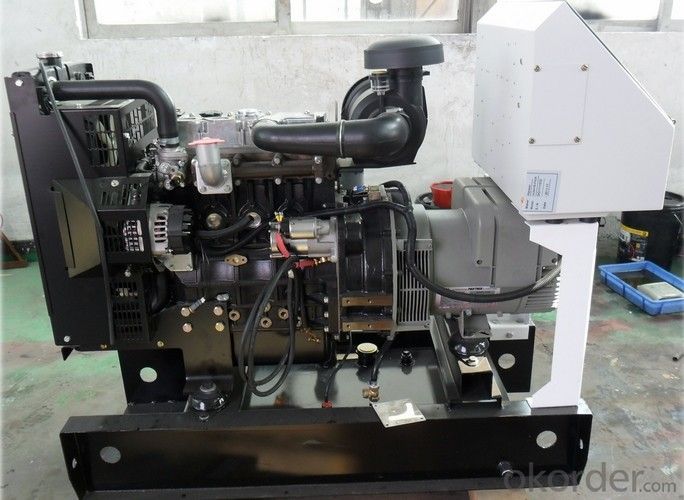

Industrial Genset Diesel Generator 36kw To 660kw With Perkins Engine

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial Genset Diesel Generator 36kw To 660kw With Perkins Engine

Quick Detail:

1.Genuine Perkins industrial diesel engine

2.Genuine stamford. Leroy somer, marathonm, engga alternator

3.Machinery or electronic governing

4.24V DC start motor and storage battery

Specifications:

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNRP10 | 7 | 9 | 8 | 10 | 403D-11 | ≤252 | 3 | 1.131 | 77*81 |

GNRP15 | 10 | 13 | 12 | 15 | 403D-15 | ≤264 | 3 | 1.496 | 84*94 |

GNRP23 | 16 | 20 | 18 | 23 | 404D-22 | ≤243 | 4 | 2.216 | 84*100 |

GNRP33 | 24 | 30 | 26 | 33 | 1103A-33G | ≤210 | 3 | 3.3 | 105*127 |

GNRP50 | 36 | 45 | 40 | 50 | 1103A-33TG1 | ≤212 | 3 | 3.3 | 105*127 |

GNRP65 | 48 | 60 | 52 | 65 | 1103A-33TG2 | ≤211 | 3 | 3.3 | 105*127 |

GNRP73 | 52 | 65 | 58 | 73 | 1104A-44TG1 | ≤207 | 4 | 4.4 | 105*127 |

GNRP88 | 64 | 80 | 70 | 88 | 1104A-44TG2 | ≤213 | 4 | 4.4 | 105*127 |

GNRP103 | 75 | 94 | 82 | 103 | 1006TG1A | ≤210 | 6 | 5.99 | 100*127 |

GNRP150 | 110 | 138 | 120 | 150 | 1006TAG | ≤205 | 6 | 5.99 | 100*127 |

GNRP165 | 120 | 150 | 132 | 165 | 1006TAG2 | ≤205 | 6 | 5.99 | 100*127 |

GNRP225E | 165 | 206 | 180 | 225 | 1306C-E87TAG3 | ≤220 | 6 | 8.7 | 117*136 |

GNRP250E | 180 | 225 | 200 | 250 | 1306C-E87TAG4 | ≤219 | 6 | 8.7 | 117*136 |

GNRP259E | 188 | 235 | 207 | 259 | 1306C-E87TAG5 | ≤221 | 6 | 8.7 | 117*136 |

GNRP275E | 200 | 250 | 220 | 275 | 1306C-E87TAG6 | ≤223 | 6 | 8.7 | 117*136 |

GNRP344E | 250 | 313 | 275 | 344 | 2206C-E13TAG2 | ≤201 | 6 | 14.6 | 137*165 |

GNRP388E | 280 | 350 | 310 | 388 | 2206C-E13TAG2 | ≤198 | 6 | 14.6 | 137*165 |

GNRP450E | 320 | 400 | 360 | 450 | 2206C-E13TAG3 | ≤201 | 6 | 14.6 | 137*165 |

GNRP500E | 360 | 450 | 400 | 500 | 2506C-E15TAG1 | ≤216 | 6 | 15 | 137*171 |

GNRP550E | 400 | 500 | 440 | 550 | 2506C-E15TAG2 | ≤211 | 6 | 15 | 137*171 |

GNRP625E | 450 | 563 | 500 | 625 | 2806A-E18TAG1A | ≤196 | 6 | 18.13 | 145*183 |

GNRP700E | 508 | 635 | 560 | 700 | 2806A-E18TAG2 | ≤203 | 6 | 18.13 | 145*183 |

GNRP800 | 580 | 725 | 640 | 800 | 4006-23TAG2A | ≤199 | 6 | 22.921 | 160*190 |

GNRP900 | 640 | 800 | 720 | 900 | 4006-23TAG3A | ≤200 | 6 | 22.921 | 160*190 |

GNRP1000 | 720 | 900 | 800 | 1000 | 4008-TAG1A | ≤206 | 8 | 30.561 | 160*190 |

GNRP1125 | 818 | 1022 | 900 | 1125 | 4008-TAG2A | ≤208 | 8 | 30.561 | 160*190 |

GNRP1375 | 1000 | 1250 | 1100 | 1375 | 4012-46TWG2A | ≤212 | 12 | 45.482 | 160*190 |

Genset Features:

1. Genuine UK industrial diesel engine

2. Radiator 40°C max, fans are driven by belt, with safety guard

3. Genuine stamford. Leroy somer, marathonm, engga alternator

4. Choice of manual/auto and AMF control panels and protection systems

5. Digital auto-start panel

6. Anti Vibration Suspension Absorber

7. Dry type air filter, fuel filter, oil filter

8. 10-hour operation base tank

9.Mould case circuit breaker

10. 24V DC start motor and storage battery

11. 24V charge alternator

12. 24V batteries, rack and cable

13. Rippl;e flex echaust pipe, exhaust siphon, flange, and muffler

14. Comply with ISO and CE standards

15. All generator sets are gone through rigorous testing before beging released to the market place, including 50% load, 75% load, 100% load and all protection function(over speed stop, high water temperature, low oil pressure, battery charging fail, emergency stop)

Engine Features:

1. Genuine UK Perkins industrial diesel engine

2. Multi-cylinder in-line or veer engine, 4-stroke, direct injection

3. Naturally aspirated, turbocharged, water cooled or turbocharged with air intercooler

4. Machinery or electronic governing

5. Fuel injection pump

6. Electric motor starting system

7. Forged steel crankshaft, cast iron cylinder and replaceable wet type cylinder liner

8. Low discharge, and low fuel consumption

9. Installed conveniently and maintain easily

Alternator Features:

1. World famous brand AC alternator: Leroy Somer, Stamford, Marathon, ENGGA

2. Brushless, 4 poles, rotation magnet

3. IP21-23(NEMA1) enclose is standard for all industrial alternators

4. H class insulation system

5. AVR self-regulated, voltage regulation rate: ≤±1%

6. Simple installation and maintenance with easy access to terminals, rotating diodes and coupling bolts

7. Wide range of flange adaptors and single bearing disc coupling

8. Radio interference restraining accords with the stipulation of VDE0875-N and ISO8528

9. Moisture proof, sand-proof, dustproof, salt-proof and vibration-proof

Digital Control panel

Controller Brand: Smartgen, Deepsea,ComAp

Control Panel: English interface,LED screen and touch buttons.

Main Functions:

1- Display loading power, voltage, currenct, frequency, speed, temperature, oil pressure, running time etc.

2- Warning when low or high voltage, low or high frequency, over current, over or low speed, low or over battery voltage etc.

3- Over load protection, over/under frequency protection, over/under/imbalance voltage protection, and low oil shutdown

Soundproof/Silent Box:

1. Excellent ventilation

2. Oil tank mounted on base frame for 12 Hours working

3. Highly Corrosion Resistant construction

4. Excellent Access for Maintenance

5. Security and Safety

6. 1m<80DBA / 7m<70DBA

Optional:

1. Trailer type

2. Soundproof / water proof

3. ATS (automatic transfer switch)

4. Parallel system

5. Remote system

PMC System:

1. Standard 23 pitch windings avoid excessive neutral current

2. Permanent magnet generator system provides constant excitation under all condition

3. Optional accessories available for easy paralleling with mains or other generators

4. AVR auto voltage regulation, auto exciter, auto adjustment

- Q: If the value of the capacitor on a motor is smaller, it can also be installed in other motors

- Don't keep using it. The capacity will continue to decrease until it is completely invalidated and has no value.

- Q: What is a hydraulic motor

- No hydraulic motor of this statement, first of all, the mean power as the driving force of mechanical, electrical and hydraulic two different drive mode, only the hydraulic pump and hydraulic motor, hydraulic pump is driven by motor, have a plenty of driven by hydraulic motor,

- Q: What's the difference between a TEFC motor and a regular motor

- The TEFC motor is a fully enclosed fan cooled motor, and the TEFC motor is a self-ventilated cold motor. Motors can be used in open or fully enclosed enclosures and can be used in very hostile environments. The air that is used for ventilation (provided by the user) enters the motor through the duct, and the heat is discharged through the duct. Cooling air is used internally or externally. Weather-proof motor is ventilated with open hull. The structure of the motor makes the electric parts of the electric parts that enter the motor, the snow, and the particles in the air to be minimized. The external air can be recycled through the motor to the cooling effect.

- Q: Is permanent magnet power saving?

- Ordinary motors require no work to build a magnetic field, and ordinary generators require a dc to create a magnetic field. Permanent magnet motors, whether motors or generators, need no work or dc to create a magnetic field. Permanent magnet motor loss, low efficiency, high cost, only for small power or special occasion.

- Q: A 2.2 KW motor will require a lot of electricity a day

- First you have to determine whether the motor is working under the rated load at 2.2 KW, which is 24 hours a day Electricity is 2.2 * 24 = 52.8 degrees. Don't need to be multiplied by three.

- Q: What is the main difference between the step motor and the ordinary motor?

- Step motor is pulse control, one pulse is a step; General electric motor is called induction motor, which is controlled by analog quantity, and the electricity is transferred.

- Q: What is the cause of the overheating of the servo motor

- 4: the inner hole of the bearing is eccentric, and the shaft is wiped. : 5: the motor ends or the bearing cover are not flat; 6: there is no calibration of the coupling between the motor and the load, or the belt is too tight; 7: the bearing clearance is too large or too small; The motor shaft bends.

- Q: Is the servo motor more than the general motors? Why is that?

- There is not much difference between a servo motor and a general motor, and there is a magnetic amplifier and a motor brake. When the motor does work, I feel the same way.

- Q: What is the difference between ordinary motor, step motor and servo?

- Step motor, rotor is permanent magnet type corresponding magnetic pole! Controlled in stator pulsed magnetic field can achieve precision step in! Apply to instrument and automatic control and drag! Less accurate than servo motor!

- Q: What is induction motor? What is the difference between ordinary motors? What is the price of a small induction motor? Is there a inductive dc motor?

- He doesn't say two to: no matter what motor (motor generator... servo. Linear motor) are all electromagnetic induction principle. Called induction motor. Ordinary asynchronous motor of motor is usually used. Is the squirrel cage.

Send your message to us

Industrial Genset Diesel Generator 36kw To 660kw With Perkins Engine

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords