Yuchai Electric Genset Diesel Generator Generating Set 800kva

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

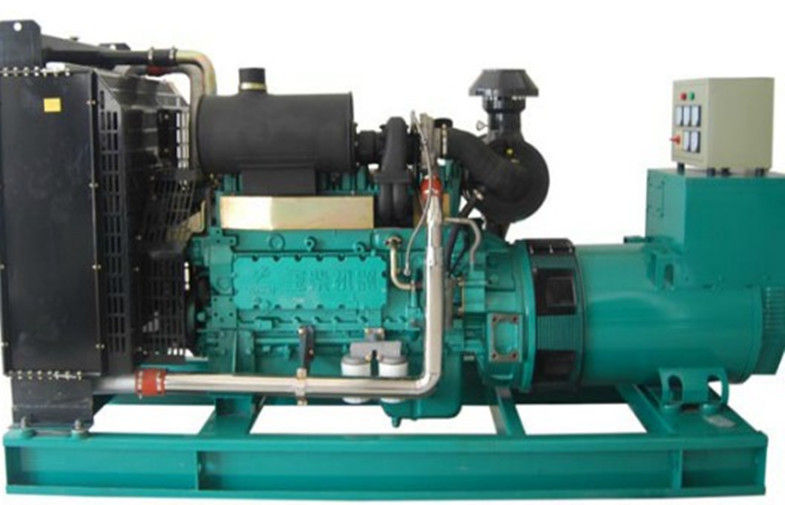

Yuchai Electric Genset Diesel Generator Generating Set 800kva

Yuchai Diesel Generator 20kva to 800kva

1.Yuchai Engine With Stamford Alternator

2. High Efficiency, H class insulation system

3.ISO 9001,1000 Hours Warranty

Specifications:

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNR-23 | 16 | 20 | 18 | 23 | YC2108D | ≤235 | 2 | 2.199 | 108*120 |

GNR-34 | 24 | 30 | 27 | 34 | YC2115D | ≤235 | 2 | 2.493 | 115*120 |

GNR-55 | 40 | 50 | 44 | 55 | YC4108D | ≤199 | 4 | 4.21 | 108*115 |

GNR-63 | 45 | 56 | 50 | 63 | YC4D70Z-D20 | ≤197 | 4 | 4.214 | 108*115 |

GNR-69 | 50 | 63 | 55 | 69 | YC4D75Z-D20 | ≤199 | 6 | 6.494 | 105*125 |

GNR-88 | 64 | 80 | 70 | 88 | YC6108D | ≤199 | 6 | 6.871 | 108*125 |

GNR-104 | 75 | 94 | 83 | 104 | YC6108ZD | ≤197 | 6 | 6.871 | 108*125 |

GNR-125 | 90 | 113 | 100 | 125 | YC6108ZLD | ≤195 | 6 | 6.871 | 108*125 |

GNR-138 | 100 | 125 | 110 | 138 | YC6B150D | ≤195 | 6 | 6.871 | 108*125 |

GNR-165 | 120 | 150 | 132 | 165 | YC6A190D | ≤195 | 6 | 7.252 | 108*132 |

GNR-206 | 150 | 188 | 165 | 206 | YC6112ZLD | ≤195 | 6 | 7.8 | 112*132 |

GNR-275 | 200 | 250 | 220 | 275 | YC6M320L-D20 | ≤189 | 6 | 9.84 | 120*145 |

GNR-481 | 350 | 438 | 385 | 481 | YCT550L-D20 | ≤192 | 6 | 15.6 | 140*155 |

GNR-550 | 400 | 500 | 440 | 550 | YC6T600L-D20 | ≤194 | 6 | 16.35 | 145*165 |

Alternator Features:

1. World famous brand AC alternator: Leroy Somer, Stamford, Marathon, ENGGA

2. Brushless, 4 poles, rotation magnet

3. IP21-23(NEMA1) enclose is standard for all industrial alternators

4. H class insulation system

5. AVR self-regulated, voltage regulation rate: ≤±1%

6. Simple installation and maintenance with easy access to terminals, rotating diodes and coupling bolts

7. Wide range of flange adaptors and single bearing disc coupling

8. Radio interference restraining accords with the stipulation of VDE0875-N and ISO8528

9. Moisture proof, sand-proof, dustproof, salt-proof and vibration-proof

Digital Control panel

Controller Brand: Smartgen, Deepsea,ComAp

Control Panel: English interface,LED screen and touch buttons.

Main Functions:

1- Display loading power, voltage, currenct, frequency, speed, temperature, oil pressure, running time etc.

2- Warning when low or high voltage, low or high frequency, over current, over or low speed, low or over battery voltage etc.

3- Over load protection, over/under frequency protection, over/under/imbalance voltage protection, and low oil shutdown

Super Soundproof/Silent Box:

1. Excellent ventilation

2. Oil tank mounted on base frame for 12 Hours working

3. Highly Corrosion Resistant construction

4. Excellent Access for Maintenance

5. Security and Safety

6. 1m<80DBA / 7m<70dba< strong="">

- Q: Is there any difference between motor and motor? A positive answer

- An electric motor is only one way of running the motor, except that the motor operates in electric mode, which converts electricity into other forms of energy. Another way of running the motor is the generator, which is then run in the mode of power generation, converting other forms of energy into electricity.

- Q: How does servo motor understand? What is a servo motor? What about motors? What's different about servo motors and other motors?

- Servo motor (servo motor) is the engine that controls the operation of mechanical components in servo systems. The servo motor can control the speed, the position precision is very accurate, can convert voltage signal to torque and speed to drive the control object. Servo motor rotor speed controlled by the input signal, and can be rapid response, in the automatic control system, is used as actuators, and has a small electromechanical time constant, high linearity, initiating character such as voltage, can convert the received electrical signal to the motor shaft angular displacement or angular velocity on output. Divided into two major categories of dc and ac servo motor, its main characteristic is, when the signal voltage is zero no rotation, speed decreases with the increase of torque and uniform.

- Q: What is the difference between a single phase motor and a two-phase machine?

- You mean should be the difference between the single-phase motor and three-phase motor, the difference between them is to use the power supply is different, single-phase motor using household electricity, three-phase industrial three-phase electric motor.

- Q: The difference between ordinary motor and permanent magnet motor

- There are two different kinds of classifications that you can't compare. Permanent magnet motor is called permanent magnet motor, not permanent magnet (electromagnet) for permanent magnet. Dc motors with direct current, no direct current (alternating current) is ac motor. A permanent magnet can be a dc motor or ac motor (for example, a home breeze fan). In the same way, no permanent magnet can be either a dc motor or ac motor, or even an alternating current.

- Q: Can I use the servo motor?

- You can use it as an ordinary motor, the premise is the drive still need to use, can be set to Cn001 is 1, speed control, select Cn002.0 is 1, do not use the input node SON control servo, servo power immediately started. The Hn505 is H010A, which selects the internal velocity; Sn201, you can set the speed you want. The two strands of the electric motor, the four line is the power, the three phase four line, the like you have been to the end to scrap more than n many RMB, the ninth line is the encoder line, must connect well. After this is done, you can be overqualified.

- Q: What is the difference between a carbon brush motor and a regular motor. Which machine is better

- Normal asynchronous motor is good, the line will run normally, the carbon brush of the carbon brush will wear out frequently, very troublesome.

- Q: Does the motor swing around?

- The motor bearing is out of question, causing the left and right oscillation.I hope my answer will help you.

- Q: My electric motor with riding a motor won't turn, idling did not move, I thought that the controller has broken a new motor does not turn other are thoroughly headlight electricity for electric machine does not move

- Check for good or bad. When the hall element is damaged, the control function is lost. Check the brake switch. The action of the left and right brake switch is to disconnect the motor power when braking. So the switch is broken and the motor is not electrified. 3, check motor and electrical circuit leads. Due to the high current of electric current and vibration, the possibility of fracture and contact is present. In addition, motor damage is not excluded.

- Q: Does the frequency conversion machine speak louder than the ordinary motor?

- This is not necessarily, the power of the motor size, also related to the noise of the motor itself, but in the case of the same parameters, the inverter will make voice be larger than ordinary motor, because through the inverter output waveform directly contains a large number of higher harmonic,

- Q: Why does the direct start-up of high power motors affect the voltage of the grid

- Because the instantaneous starting current of the three-phase machine is five to seven times the rated electric current, the voltage of the line is reduced, and the voltage of the power grid and the zhou wave are low. Therefore, the high power motor should be initiated by star/Angle to reduce the starting current and avoid the large fluctuation in the voltage of the grid. The star triangulation is initiated by changing the connection of the motor winding, and the pressure is actuated. When activated, the main contactor will give the power to the three ends of the motor winding, which will close the three ends of the motor winding. Winding becomes a star connection, after the completion of the start, time relay action, star contactor disconnect, contactor operation will be three of the power supply to the motor winding end. The winding becomes a delta connection. The motor is fully pressed. During startup, the asterisk contactor and the operating contactor must be interlinked. Image: KT - time relay, KM1 - star contactor, KM2 - the main contactor, KM3 - the operating contactor.

Send your message to us

Yuchai Electric Genset Diesel Generator Generating Set 800kva

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches