IPEAA IPE/ beam steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

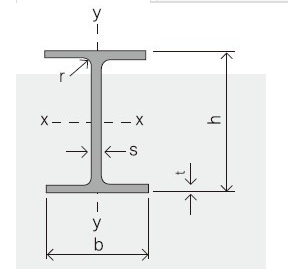

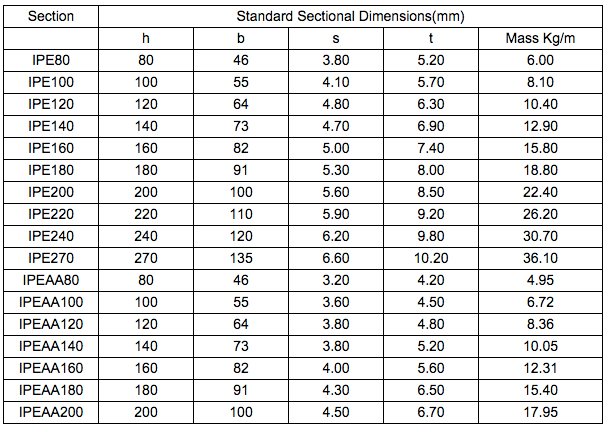

Specifications of IPE/IPEAA Beam Steel

1. Product name: IPE/IPEAA Beam Steel

2. Standard: EN10025, GB Standard, ASTM, JIS etc.

3. Grade: Q235B, A36, S235JR, Q345, SS400 or other equivalent.

4. Length: 5.8M, 6M, 9M, 10M, 12M or as your requirements

Applications of IPE/IPEAA Beam Steel

IPE/IPEAA Beam Steel are widely used in various construction structures, bridges, autos, brackets, mechanisms and so on.

Packing & Delivery Terms of IPE/IPEAA Beam Steel

1. Package: All the IPE/IPEAA Beam Steel will be tired by wire rod in bundles

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Shipment: In containers or in bulk cargo

5. Delivery time: All the IPE/IPEAA Beam Steel will be at the port of the shipment within 45 days after receiving the L/C at sight ot the advance pyment.

6. Payment: L/C at sight; 30% advance payment before production, 70% before shipment by T/T, etc.

Production flow of IPE/IPEAA Beams

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel I-beams be used for schools and universities?

- Schools and universities can indeed utilize steel I-beams. These beams are widely employed in the construction field owing to their robustness, endurance, and adaptability. Their exceptional load-bearing capacity makes them suitable for supporting the weight of large structures such as educational institutions. Moreover, the fabrication and installation of steel I-beams are relatively simple, allowing for efficient construction procedures. Furthermore, steel is a non-combustible material, a crucial factor in ensuring the safety of the building's occupants. In conclusion, steel I-beams are a favored option for building schools and universities because of their structural integrity, cost-effectiveness, and compliance with necessary building codes and regulations.

- Q: What are the different types of connections used with steel I-beams?

- Steel I-beams can be connected using various methods, each with its own purpose and advantages. Here are several common connection types: 1. Welded connections: The most commonly used method involves welding the beam flanges or web to other structural members. This creates a strong and rigid connection, ensuring excellent strength and stiffness. 2. Bolted connections: Bolts, nuts, and washers are used to connect steel I-beams. These connections are ideal for situations where future disassembly or modification may be necessary. They offer easy installation and can be quickly assembled or disassembled, providing flexibility. 3. Riveted connections: In the past, hot-driven rivets were frequently used, but they have now been largely replaced by welded or bolted connections. Riveted connections offer good strength and durability but are more time-consuming and require skilled labor for installation. 4. Moment connections: Welded or bolted connections that allow rotational movement between connected members are known as moment connections. These connections transfer bending moments between beams and columns, providing stability and resistance against lateral forces. They are commonly found in steel frame structures designed to withstand significant loads and forces. 5. Shear connections: Shear connections transfer shear forces between steel I-beams. They can be achieved through welding or bolting plates or angles to the beam flanges. Shear connections ensure load transfer between beams, enhancing overall stability and rigidity. 6. Cleat connections: Cleat connections involve attaching a steel plate, called a cleat, to the flanges of the steel I-beam using bolts. This type of connection is commonly used when the beam needs to be connected to a support or another structural member, such as in roof or floor systems. These examples demonstrate the various connections used with steel I-beams. The choice of connection depends on factors such as load requirements, structural design, ease of installation, and future flexibility. It is advisable to consult with a structural engineer or a professional in the field to determine the most suitable connection for a specific application.

- Q: How do steel I-beams perform in terms of vibration insulation?

- Steel I-beams are not effective in terms of vibration insulation. They have a high stiffness and low damping capacity, which means they transmit vibrations easily rather than attenuating them.

- Q: The difference between I-beam and wide flange I-beam

- You say wide flange I-beam is hot rolled H steel, is the HW series.

- Q: Can steel I-beams be used in parking structures?

- Yes, steel I-beams can be used in parking structures. Steel I-beams are commonly used in the construction of parking structures due to their strength, durability, and ability to support heavy loads. They provide structural stability and can span long distances, allowing for open and flexible parking layouts. Additionally, steel I-beams have a high resistance to fire, making them a safe choice for parking structures. Their versatility and cost-effectiveness make steel I-beams a popular choice among architects and engineers when designing parking structures.

- Q: What are the different types of steel connections used for I-beams?

- There are several different types of steel connections used for I-beams, including welded connections, bolted connections, and riveted connections. Welded connections involve joining the I-beam to another structural member through the process of welding. Bolted connections involve using bolts and nuts to connect the I-beam to other members, providing a strong and adjustable connection. Riveted connections involve using rivets to fasten the I-beam to other members, creating a secure and durable connection. Each type of connection has its advantages and is used based on the specific requirements and design considerations of the structure.

- Q: What type of channel steel and I-beam should be used to build an attic floor? Thank you!

- With 20 I-beam, the distance can be controlled to 1.6 meters. With channel, then the spacing to control 1.2 meters more appropriate, the middle should use angle steel to do cross brace.

- Q: How do steel I-beams contribute to the overall cost-effectiveness of a construction project?

- There are several ways in which steel I-beams contribute to the overall cost-effectiveness of a construction project. To begin with, their exceptional strength and durability enable the construction of structures that can withstand heavy loads and harsh weather conditions. This means that fewer beams are necessary to support the same weight compared to other materials, resulting in savings on both materials and labor. Moreover, steel I-beams offer great versatility and can be easily fabricated and customized to meet specific project requirements. They can be cut, welded, and shaped to fit different designs and structural needs, thereby reducing waste and eliminating the need for excessive on-site modifications. This adaptability also facilitates quicker construction, reducing labor costs and project timelines. Additionally, steel I-beams boast a long lifespan and require minimal maintenance when compared to other materials. They are highly resistant to corrosion, pests, and fire, thereby reducing the need for regular repairs and replacements. This longevity translates into long-term cost savings for the project owner, as there is less expenditure on maintenance and replacement over the life cycle of the structure. Lastly, steel I-beams are readily available from various suppliers, making them a cost-effective choice for construction projects. The competitive market for steel materials ensures reasonable pricing and access to a wide range of options, enabling project managers to select the most cost-efficient solution that meets their quality requirements. In summary, the utilization of steel I-beams in construction projects improves cost-effectiveness by reducing material and labor costs, facilitating faster construction, minimizing maintenance needs, and providing affordable options.

- Q: Can steel I-beams be used for manufacturing plants?

- Indeed, manufacturing plants can utilize steel I-beams. These beams are extensively employed in the construction field owing to their remarkable strength-to-weight ratio and adaptability. They offer exceptional structural reinforcement, capable of enduring substantial burdens, which renders them perfect for deployment in manufacturing plants where heavy machinery and equipment are prevalent. Moreover, steel I-beams boast long-lasting sturdiness, as they are impervious to corrosion and capable of withstanding harsh environmental circumstances. Furthermore, their straightforward installation process and potential for customization to meet specific project demands contribute to their widespread popularity in manufacturing plants.

- Q: Can steel I-beams be used in sustainable or green building practices?

- Yes, steel I-beams can certainly be used in sustainable or green building practices. Steel is a highly sustainable material with a long lifespan, and it can be recycled indefinitely without losing its strength or quality. Using steel I-beams in construction allows for larger open spaces and more flexible designs, reducing the need for additional columns or supports. This maximizes natural light and airflow, reducing the reliance on artificial lighting and air conditioning, which in turn reduces energy consumption. Steel I-beams are also highly durable and resistant to fire, pests, and extreme weather conditions. This durability means that buildings constructed with steel I-beams have a longer lifespan and require fewer repairs and maintenance, resulting in reduced waste and environmental impact. Furthermore, using steel I-beams can contribute to energy efficiency by facilitating the installation of insulation materials, which help in maintaining a comfortable indoor temperature and reducing the need for heating or cooling. Lastly, steel is a material that can be sourced locally, reducing transportation emissions associated with long-distance shipping. Additionally, steel production has become more energy-efficient and environmentally friendly in recent years, further enhancing the sustainability of using steel I-beams in construction. In conclusion, steel I-beams offer numerous advantages for sustainable or green building practices. From their recyclability and durability to their energy efficiency and local sourcing potential, steel I-beams are a viable option for those seeking to construct environmentally friendly and sustainable buildings.

Send your message to us

IPEAA IPE/ beam steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords