Mild Steel Double T Equivalent to I Beam Small and Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Mild Steel Double T Equivalent to I Beam Description:

Mild steel double T equivalent to I beam is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Mild steel double T equivalent to I beam is usually made of structural steel and is used in construction and civil engineering. The mild steel double T equivalent to I beam resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Mild steel double T equivalent to I beam theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam Bar IPE Images:

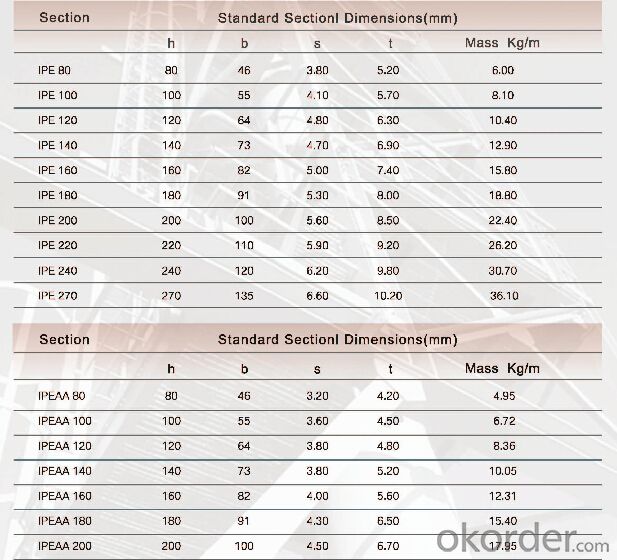

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: What are the common challenges in transporting and handling steel I-beams?

- Transporting and handling steel I-beams can pose several common challenges. One of the main challenges is the sheer size and weight of the I-beams. These beams can be extremely large and heavy, making it difficult to maneuver and transport them safely. Specialized equipment such as cranes, forklifts, and trailers with appropriate weight-bearing capacities are needed to handle these heavy loads. Another challenge is ensuring proper securing of the I-beams during transportation. These beams can be susceptible to shifting or rolling if they are not properly secured. This can lead to damage to the beams themselves, as well as potential accidents or injuries to personnel involved in the transportation process. Adequate strapping, padding, and bracing must be used to secure the I-beams and prevent any movement during transit. The shape of I-beams can also present challenges during handling. Their unique shape and design can make it difficult to stack or store them efficiently. Special care must be taken to ensure that I-beams are stored in a manner that prevents them from becoming damaged or deformed. Additionally, the shape of the I-beams can make it difficult to handle them manually, requiring the use of specialized lifting equipment or machinery. Lastly, the length of I-beams can also be a challenge during transportation. These beams can range in length, sometimes exceeding the length of standard trailers or shipping containers. This requires careful planning to ensure that the transportation method can accommodate the length of the I-beams. Special permits or escorts may be required for oversized loads, and routes must be carefully selected to avoid any height or width restrictions. In summary, the common challenges in transporting and handling steel I-beams include their large size and weight, the need for proper securing during transportation, the unique shape of the beams, and the potential length constraints. Overcoming these challenges requires specialized equipment, careful planning, and adherence to safety protocols to ensure the safe and efficient transportation of steel I-beams.

- Q: Can Steel I-Beams be used for healthcare facilities like hospitals?

- Certainly! Steel I-Beams have proven to be a viable option for healthcare facilities such as hospitals. These I-Beams are frequently utilized in construction projects due to their exceptional strength and durability. They possess the capability to bear heavy loads and provide structural stability, thereby rendering them suitable for various types of buildings, including healthcare facilities. In the case of hospitals, it is often necessary to have large, open areas to accommodate medical equipment and allow for future renovations. By using Steel I-Beams, long distances can be spanned without the need for excessive vertical support, thereby affording more flexibility in the design of healthcare facilities. Moreover, steel exhibits resistance to fire, pests, and rot, thus making it an exceptionally reliable choice for healthcare establishments that prioritize safety and long-term viability.

- Q: How are steel I-beams sized and classified?

- Steel I-beams are sized and classified based on their dimensions, particularly their depth, width, and weight per foot. The size and classification of steel I-beams are determined by industry standards and specifications, such as the American Institute of Steel Construction (AISC) standards. These standards ensure that I-beams are designed and manufactured to support specific loads and structural requirements.

- Q: What are the common design considerations when using steel I-beams?

- Some common design considerations when using steel I-beams include determining the appropriate size and shape of the beam based on the structural load it needs to support, calculating the required strength and stiffness to ensure structural stability, considering the potential for deflection and buckling under load, and incorporating appropriate connections and supports to ensure proper installation and performance. Additionally, factors such as fire resistance, corrosion protection, and cost-effectiveness may also be taken into account during the design process.

- Q: Span seven meters of suspended beam, can I put a beam inside the beam with pouring, increase the intensity?

- cannotBecause the frame structure should not only bear vertical load due to horizontal loads caused by earthquake to resist or windThere is tension in the upper and lower beams of the beam, if the span of the beam would like to replace the bar by means of I-beamThat I-beam will be super, it would be more uneconomical, it is better to do directly steel frame, facade room to the happy, but also reduce the load

- Q: Can steel I-beams be used in hospitality or hotel construction?

- Certainly, hospitality or hotel construction can definitely make use of steel I-beams. In fact, steel is widely employed in the construction industry due to its exceptional strength, durability, and versatility. The use of steel I-beams is particularly favored because of their capacity to bear heavy loads and provide structural stability. Such beams are frequently employed in the construction of expansive structures like hotels, where the necessity for a robust and reliable support system is of utmost importance. Steel I-beams find various applications in hotel construction, such as sustaining the weight of the building, facilitating open floor plans, and furnishing a framework for the installation of mechanical, electrical, and plumbing systems. Moreover, steel I-beams present numerous advantages for hotel construction, including their ability to span long distances without requiring intermediate supports, their resistance to fire and pests, and their ease of installation. Overall, steel I-beams are a viable and popular option for hospitality or hotel construction endeavors.

- Q: Can I ask the steel structure of my family to do this? Decoration company in order to save costs, with the I-beam in the load wall at both ends, in the middle with channel welding

- If you have done well, then there is no way, it depends on your habits are not used, the steel structure in a short time can not be a problem

- Q: How are steel I-beams protected against rust?

- Steel I-beams are protected against rust through a process called corrosion protection. There are several methods used to prevent rusting and extend the lifespan of steel I-beams. One common method is the application of a coating or paint on the surface of the I-beams. The coating acts as a barrier between the steel and the surrounding environment, preventing moisture and oxygen from coming into contact with the metal. This helps to inhibit the formation of rust. Another method is the use of galvanization. In this process, the I-beams are dipped into a bath of molten zinc. The zinc coating forms a protective layer on the surface of the steel, acting as a sacrificial barrier. If any part of the steel is exposed due to damage, the zinc coating will corrode instead of the steel, providing ongoing protection against rust. Additionally, some manufacturers may use a combination of coatings and galvanization to provide enhanced protection against rust. These additional layers can further increase the resistance of the I-beams to corrosion. Regular maintenance and inspection also play a crucial role in protecting steel I-beams against rust. Any damage or signs of rust should be promptly addressed to prevent further corrosion. This may involve cleaning, re-coating, or repairing the affected areas. By implementing these protective measures, steel I-beams can have a significantly extended lifespan and maintain their structural integrity over time.

- Q: Can steel I-beams be used for industrial platforms?

- Yes, steel I-beams can be used for industrial platforms. Steel I-beams are a popular choice for industrial platforms due to their strength and durability. They are capable of supporting heavy loads and are resistant to bending or warping, making them ideal for industrial applications. Additionally, steel I-beams can be easily fabricated and customized to specific size and shape requirements, allowing for flexibility in design. Overall, steel I-beams are a reliable and cost-effective option for constructing industrial platforms.

- Q: Can steel I-beams be used for industrial machinery?

- Absolutely, industrial machinery can indeed utilize steel I-beams. Renowned for their robustness and resilience, steel I-beams prove themselves versatile in a multitude of industrial applications. With their exceptional structural integrity and capacity to bear heavy loads, they excel at providing unwavering support for hefty machinery and equipment. Furthermore, their ability to endure immense pressure and furnish a steadfast and secure framework renders them a preferred choice in factories, production facilities, and other industrial environments necessitating sturdy support structures.

Send your message to us

Mild Steel Double T Equivalent to I Beam Small and Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords