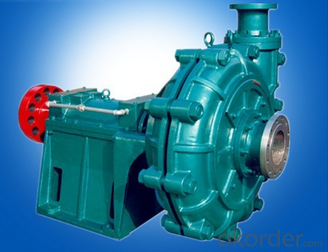

HZJ Series Heavy Duty Slurry Pump(ISO2858, ISO5199, API682)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

Conform tp ISO2858, ISO5199, API682 standard

Max operating pressure 2.5Mpa

Range of capacity 4~3240m3/h

Total head 7~115m

Range of operating temperature -20~180oC

Max particle diameters 3~115mm

Max solid content 60%

2. Application

It is used to convey high-concentrated corrosive slurry containing a great deal of solid materials.

3. Materials

For wetted parts in contact with medium, the common materials are as followings,

MCU, DTM, M-3, and Cr15Mo3.

4. Pump Seal

171C, 171CL mechanical seal

Dynamic seal

5. FAQ

1 How can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2 Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3 Do you have self-priming pumps?

Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

- Q: i have a 1996 camaro rs v6 that needs a new water pump, the old one is leaking from a failsafe type hole.i know that im probably not gonna get one but its simply the perfect time to so if i am so... but should i consider getting an electric water pump instead of the $50 origional replacement? the car has no 'real' mods and i know the electric water pump would be a two horse difference, and that it is a mostly race type modification. so i had to ask because if i was to do this mod, now is the time. so what do you think? things like average cost of a good name like meziere , how hard to wire, etc.thanks

- Get.the.normal hose then think bout what you need to do

- Q: starting from the water pump, and returning to the water pump

- Most cooling systems pump the coolant out of the engine through the top radiator hose. In the radiator. Out the radiator through the bottom hose. A by-pass system can be found on most cars and it includes the water pump and smaller diameter hose.l these smaller hoses rout the collant to certain components such as the heater core (which provides passenger compartment comfort). There many other variables depending of the car. Engine oil coolers. Intake manifold warm-up passages, I may be leaving some info out here but that is pretty much your basic cooling system routing. Best wishes.

- Q: Can I charge the battery (1.2Vx2) with the suction tube submerged in the water or do I have to remove the suction tube every time I have to charge the battery?

- Since you don't mention the model of the pump, if you can connect the charger with a dry connection, you should not have to remove the pump/tube. If you have to take the battery out, you stand the risk of dropping it in the water putting it back, but obviously (I think) you don't have to remove the pump/tube.

- Q: I have a 2004 Toyota Sienna and it has 80k+ miles on it. I guess it is the drive belt that is making the noise and I decide to have it changed. I can have the timing belt changed too because it is due at 90k miles. The dealer guy told me that I should also have the water pump changed too because of 2 reasons:1. the new timing belt will cause pressure to the old water pump. If not changed, it will leak in weeks.2. it is cheaper to do it altogether.Without changing the water pump, it would cost about $300.All would cost $1000+.My friend who also has a Sienna that has more miles on it, told me that he did not have to change the water pump.Your advice about the water pump is?

- This Site Might Help You. RE: About drive-belt, timing belt, and water pump of a Tpyota Sienna? I have a 2004 Toyota Sienna and it has 80k+ miles on it. I guess it is the drive belt that is making the noise and I decide to have it changed. I can have the timing belt changed too because it is due at 90k miles. The dealer guy told me that I should also have the water pump changed too...

- Q: Multi storey residential buildings also need to set up pressurized water pump room, direct water supply can not be?

- The tap water supply pressure is enough, so there is no need to pressurize.

- Q: Ok, simple question, on a 1992 Jeep Cherokee 4.0. The water pump sucks water (not push) through the heater core correct? So the flow of water goes from the block, through the heater core, into the water pump, right?

- the pump does what it say pump.... it flows thru the radiator to the block and back ..... if you having a problem with heat then it could be stoped up and need a new one .... over heating therostat.... id say yes it sucks thru the motor if the hose is hook to the motor

- Q: I have a 2006 Mitsubishi Raider that I'm pretty sure needs a new water pump. It is still under warranty for another 1000 miles, but the nearest dealer is over 200 miles away, and Mitsubishi says they won't reimburse for work done at a non-Mitsubishi Dealer. I'm trying to figure out if the cost of just paying someone to have it done here in town versus having towed 200 miles and then driving it back, plus the lost cost of missed work.By the way my Mitsubishi Roadside Assistance will tow it to the nearest dealer for free, but last time I did that it was barely worth the hassle of dealing with their very poor contract towers.

- Have you asked the dealer to send you the part at least? Call Mitsubishi and ask it that would be possible, you never know. You could send in the old pump and possibly get compensation. Keep your bills. Discuss it with them. Your dealer should provide you with the area Mitsubishi representatives contact information. The prices for those can be expensive. Ask the dealer, service dept, for the labour, how many hrs. to change the pump. They should tell you. Also for the cost of the pump. Add the two together and you have your ans. Join CAA, or AAA, get a gold card, wait two days for the card's towing to take effect, then have it towed in on the card. Done all the time. Or if you have a relative with a Gold card they can have it towed in as long as they are with the car with their card when the tow truck comes.

- Q: My dads needs a new water pump for his '83 Silverado v8, anyone have a DIY or a schematic or know of where I can find one? Maybe someone could tell me how. He's pretty handy with cars just doesn't know what needs to come off and in what order. -Thanks in advance!

- remove the fan shroud , then the then belt, then the fan. drain coolant then remove hoses from pump. then the water pump .. it is a 2 hour job at most . can be done as little as a hour if you have the right tools and understand the job. you will need special too to remove fan. rest is 10mm 13mm , 14mm or 15 mm bolts .. press clamps need pliers or flat screw driver to remove clamps .

- Q: i am not sure whether the water pump is bad or how much water should come out of exhaust.

- take it in.

- Q: I need to install water pump and need to know the cost already purchase pump

- Depends on what engine and drivetrain you have. If it's a v6 rear-wheel-drive, you're probably looking in the neighborhood of about $650 USD. If it's a v8 all wheel drive, then you're probably looking more around $850 USD. That's for a timing belt and water pump replacement at most shops.

Send your message to us

HZJ Series Heavy Duty Slurry Pump(ISO2858, ISO5199, API682)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords