HYK/HYS Series Chemical Submerged Pump(API 610)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

HYK series chemical submerged pump

Conform to API610 standard

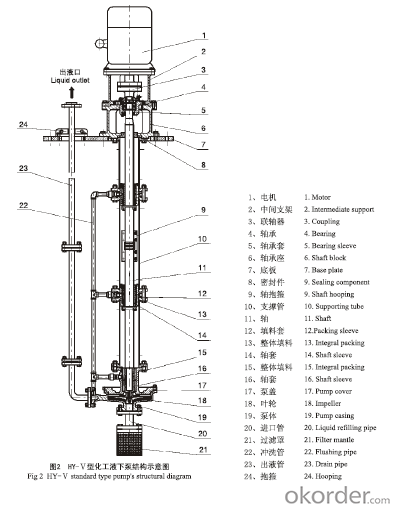

Vertical centrifugal pump of single stage, end suction, with open impeller.

HYS has the same structure and performance with HYK series pump. The wetted parts can be used the special material, suitable for the high temperature, high concentration liquids, such as concentrated sulfuric acid and in other acid environments.

2. Technical Data

Capacity: 6~400m3/h

Head: 5~80

Temperature: -20~200℃

Nozzles: DN25~150mm

Pressure: 2.0MPa

3. Application

Paper-making, metallurgical, fertilizers, salt collecting, drainage industries.

Conveying the pulp below 8% density and other liquid with the solid content below 30%

4. Materials

For wetted parts in contact with medium, the common materials are as followings:

S.S.304, 316, 316L, TA2, MCU, DTM, Cr15Mo3, M-3 etc.

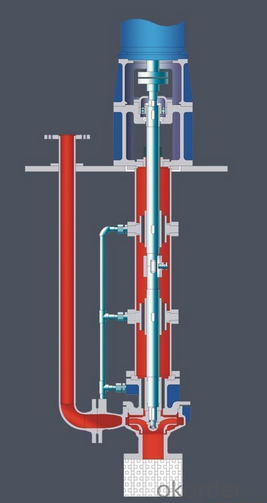

5. Pump Structure

6. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

5 Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

- Q: I have 2004 Chevy Trailblazer V8 4x4 that the water pump went out on. Does anyone know how long it takes to change it and where it is located? The dealer wants $750.00 to fix it. I really don't want to get riped off.

- 2004 Trail Blazer

- Q: My water pump was replaced 3 months ago,but it stopped spraying water yesterday, How do I unclog the intake / Outflow?

- check the thermostat, it could be clogged.

- Q: An engineer is given the job of designing the water system for a tall building. He decides to locate the pumps at ground level and feed the entire building from there. If the top floor of the building is 236 m above ground level, what must the pressure be at pump level?

- Adding to Colin's answer, in addition to pgh, you also must add the atmospheric pressure, which is the pressure caused by the air at roughly the Earth's surface, unless whatever vessel the engineering is trying to pump the water into is a vacuum or otherwise not exposed to the air outside. atmospheric pressure: 1 atm = 1.013 x 10^5 Pa

- Q: i used my water fountain pump for the first time yesterday and I've had it for 10 years and i used it yesterday it worked with the water and everything was fine!then the next day i wanted to turn it on , it went on it started vibrating but it wasn't pumpingwhen i had it on the other day the water was dirty but it was workingi cleaned it the filtershould i put vinegar to clean it ?and what else should i do!??? Help :#92;thank you!

- Totally agree with Peetr Peetr's answer above. When you purchase the trashcan the Rubbermaid cans have been proven to be safe for potable water, can't say that all others will be made with non leaching plastics. Also Suggest adding the dechlorinating product i.e. prime into the tank itself, instead of adding it to the water and sitting all week in the vessel which leaves a layer of scum on the trashcan from my experience. Hth

- Q: I've always wondered how a water pump moves water through a pipe. A fan moves air by spinning a propeller-like set of blades, but does a water pump work the same way? Or is there some other kind of mechanism inside the pump that draws water from one place and pushes it to another?

- How Do Water Pumps Work

- Q: What is a water pump for?

- Providing kinetic energy to increase the flow of liquid to an energy increasing device for required head and flow

- Q: What is the reason for the overload of the water pump indicator?

- In this case, first check the frequency of the pump in the acceleration and deceleration time, to see how many seconds, 7.5KW10 seconds or so, 11KW 10 to 15 seconds, to see whether the peak water supply, low voltage and so on! Hope to be of some help to you!

- Q: What motor does the pump use?

- Hello, the pump is generally used permanent magnet synchronous motor, and if the motor is not too understand, you can consult the motor suppliers, according to the model to choose their own use.

- Q: i am not sure whether the water pump is bad or how much water should come out of exhaust.

- It may not be your water pump at all. It could be a blown head gasket or a cracked block. Do you drive it very much? If you do and it doesn't totally overheat, it isn't your water pump. Water pumps usually tend to make a lot of noise when they go bad. Depending on the temperature of the air where you live, I would say don't worry too much about white clouds coming out of your exhaust. You do notice I said white? Condensation in an exhaust pipe is normal. Check the little stuff first. Check your thermostat and radiator cap first. Those are inexpensive. Have your radiator checked at the local Mom and Pop radiator shop where they will also check your hoses and engine oil, to see if it looks like mud. That will tell you if you have a cracked block. Total overheating can be a blown head gasket which is expensive because of labor. The parts cost is minimal, it is just a total b i t c h because you have to get the whole top of the motor off. Have your freeze plugs checked too and if they are plastic, have them replaced with brass ones. It is a very old vehicle and you are going to be looking at some money to fix things. I hope I helped, although you didn't tell me the name of the vehicle. That would help a bit more and if you know it is the water pump, go get a new one!!!!!!! And check your fan belts too while you're at it. Good luck! :) I'm just a dumb lady...lol!

- Q: Help?Water is to be pumped to the top of a skyscraper. If the pump can create a gauge pressure (pressure above atmospheric pressure) of 8.50E+5 Pa, what is the height of the tallest building that it can service? DATA: g=9.8 m/s^2

- IF the pump can produce a static pressure of 8.5e+5 Pa, then it can support a column of water, h h = P/(rho*g) = 8.5e+5/(1000*9.8) = 86.7 m h = 87m Now, the water will have no velocity, so you can't use it effectively, but that's not what the problem asks!

Send your message to us

HYK/HYS Series Chemical Submerged Pump(API 610)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords