HY Series Chemical Submerged Pump(API 610)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

HY series chemical submerged pump

Vertical centrifugal pump of single stage, end suction, with innovative design, energy-saving and green products.

Conform to API610 standard

2. Technical Data

Capacity: 3~3400m3/h

Head: 5~100

Temperature: -20~200℃

Nozzles: DN25~500mm

Pressure: 2.5MPa

3. Application

Petrochemical, chemical, metallurgical, depot, sewage treatment industries

Conveying toxic and corrosive liquid which is clean or contains only very little suspended particles and crystallized substances.

4. Materials

For wetted parts in contact with medium, the common materials are as followings:

S.S.304, 316, 316L, TA2, MCU, DTM, Cr15Mo3, M-3 etc.

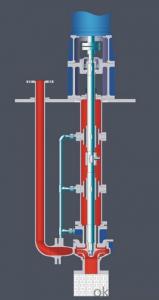

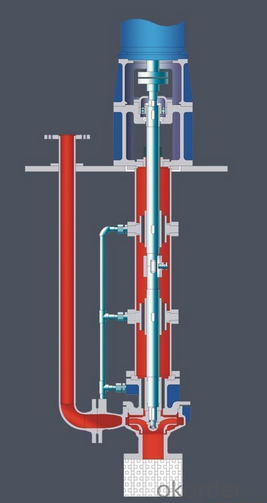

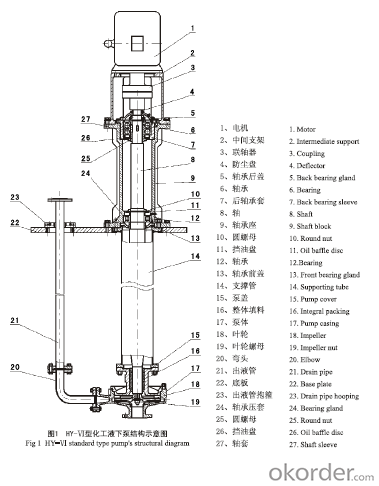

5. Pump Structure

6. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

5 Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

- Q: 1978 Ranchero 500. Pumps leaking like crazy. I have a belt to remove, which i assume is the serpentine belt? Its tight as can be on the pulleys. I have no clue how to remove this and any other advice on this do-it-yourself project would be much appreciated. Thanks

- being a 78 it probably has a V belt instead of a serpentine belt. you loosen the adjustment bolt on the alternator and the long through bolt, push the alternator and the belt should come off. you will need to take the fan off, it should have 4 bolts to take out to remove the fan. then you take the hose off after you drain the radiator and take out the water pump bolts and pry off the pump. now before installing the new pump make sure the gasket surface is clean and dry. put some good sealer on both sides of the gasket. to keep the gasket from moving i use string like thread and tie the gasket on. put the pump in place, put the bolts back in and tighten them, put the hose back on, put the fan back on and tighten the bolts and refill the radiator. if you want good sealer use what i use. i use indian head shellac. once that stuff gets set up it won,t leak. auto zone sells it in a small brown bottle.

- Q: Suppose the liquid temperature range for the water pump is -20 .. 90 °C. However it should be worked under liquid temperature upto 180 °C. For this, what has to to be done?

- (edited) The physical size of the pumping arrangement was not described. I assume that the pump has all metallic components because of the high (194 F) 90degC design operating temperature. There may be some problem with an elastomeric bellows in a mechanical seal at the 180degC (356F) temperature. Other than that, there should be no problem with the temperatures as far as the pump is concerned. There may be a need for shaft cooling to protect the standard electric motor and possibly the flexible drive coupling arrangement. (edit) Depending on the physical size, rotating speed and drive arrangement, a special coupling set-up may be needed to accommodate any potentially wide swing in operating temperatures. From ambient to 180degC there will be about a 160C (288F) variation. The liquid will be either a salt or a glycol brine solution for freeze protection at the lower temperatures. (edit) That same concentration will provide some elevation of the boiling temperature and therefore a reduction of the pressure of the water solution needed to prevent boiling. ( 130 psig is the saturation pressure of plain water at that elevated temperature.) This can be found on the charts provided by the glycol suppliers for the various glycol and salt solution characteristics. To prevent cavitation you may need to pressurize the suction. If the proposed pressure of the system is already above the vapor pressure of the solution at that maximum temperature, you may already be OK. A motor with high temperature windings may be considered.

- Q: antifreeze leaking from the water pump. antifreeze wont stay in car, car overheating. 96 chevy cavalier. 2.4

- Is it leaking from the waterpump itself or the gasket.It may be overheating because its out of water rather than a faulty water pump if the gasket is bad.

- Q: I have a 1997 Saturn SL2 and I was wondering how much would it be to replace the water pump? Would it be less expensive if I took it to a neighborhood mechanic instead a more popular one like Goodyear or something? Thanks for looking.

- i just replaced my water pump on my jeep, the whole water pump kit was about $59.99 with lifetime warranty, most mechanics charge alot to do it, i did it myself, you just need a water pump, gasket, coolant draining pan, bottle of coolant and the procedure is pretty easy

- Q: How do I replace the water pump on a 1996 Mercury 200 hp outboard engine? I have the parts, but want to make sure I replace it correctly. Thanks!

- Hey follow Mark T's Instructions, But I always place the lower unit in full forward gear first it makes it easier to line up the drive shaft by giving the prop a tweak and its easier unless you have someone to turn the flywheel for you.

- Q: Just touch this area, a lot of places do not understandFor example, I have a water pump, for 11kw, choose circuit breaker, then what model should be chosen more appropriate, it is best to recommend a Schneider, universal DW recommend oneCan explain in detail, better, I checked online selection manual, there are many places that feel fuzzyIn addition, 37KW, 22KW, 1.5KW each choose what type?Hope predecessors give advice

- Schneider circuit breaker is not selected, I do not know how much current to drive the 11kw pump, and there is no other load?

- Q: how do you change the water pump

- When you change the timing belt you as well change the water pump as well. If you take it to anyone for timing belt change they will ask you if you want to change water pump because its convenient to change it out at that time. But if you dont have any knowledge how to work with the timing dont mess with it take it to someone who is knows what there doing because paying couple hundred dollars is better then paying thousands for engine rebuild or new engine.

- Q: Water is pumped through a pipe of diameter 13.0 cm from the Colorado River up to Grand Canyon Village, on the rim of the canyon. The river is at 564 m elevation and the village is at 2311 m.(a) At what minimum pressure must the water be pumped to arrive at the village? (in MPa)b) If 4300 m3 are pumped per day, what is the speed of the water in the pipe? (in m/s)(c) What additional pressure is necessary to deliver this flow? Note: You may assume that the free-fall acceleration and the density of air are constant over the given range of elevations.( in kPa)I have tried this over and over but i know B it is 3.75 m/s please help if you know to do this THANKS!!!!!

- a) Pressure is the weight of a 1 meter square column of water. The height of the pipe is 2311-564 = 1747 m volume is 1747 m? density of water is density of water at 20C = 0.998 g/cm? = 998 kg/m? mass of water is 1747 m? x 998 kg/m? = 1744000 kg weight of water is 1744000 x 9.8 = 17090000 N Pressure is 17090000 N/m? or 17.09 MP b) Cross sectional are of pipe is A = πr? A = π(.065)? = 0.0133 m? one meter of pipe has a volume of .0133 m? 4300 m? are pumped per day The water in that one meter of pipe has to be changed 4300 / 0133 = 324000 times per day to handle the flow That is 324000 / (24*3600) times per second or 3.75 times per second. Since the section of pipe is is 1 meter, that is 3.75 meters per second.

- Q: Hey for the past month my car has been leaking coolant, making a wierd noise when i drive it, and saying low coolant when its filled to the top.my husband took it out to get gas this morning and it stopped on him and had to be towed to the mechanicthe mechanic said its the water pump and somethin about anti freeze and this cost almost 300 bucks with parts and laborim just wanting to know if a water pump does indeed cause issues like this before we dish out this kinda money!!! btw its a 96 chevy luminathanks

- The water pump pumps cooled water around the engine, so yes if it has an issue like leaking then there is a very high chance that the engine will overheat. Anti-freeze is only really required in the winter when temperatures get low enough to freeze the water in the system and therefore will not be able to be pumped around the engine, as it's now summer there is no danger not using anti-freeze but is advisable to get some added before the cold weather comes.

- Q: Work done in water pumping?Water is to be brought from a well 60 meters bellow ground level to a tower 10 meters high, once there the water falls freely on a 5000 liter tank. A submerged pump 10 meters under water level and a two inch diameter pipe is to be used. What is the work done by the pump when 2000 liters have been served to the tank; what is the power of a pump selected to do this work in 20 minutes.

- Power_W = (Mass_kg * Gravity_m/s/s * Height_m) / time_s Where: Mass kg is 1kg/l of 2000 liters Gravity is 9.81m/s/s Head is 60m + 10m (height). The suction head is ignored because the pump is submerged. In practice there is some suction head due to intake restrictions like pipes, check valves, strainers. The time is 20 minutes in seconds. The work is the energy used in the time allocated, which is: power * time in seconds, which is watt seconds = joules. Not needed here as it is in the formula above. Power is the rate of doing work. The depth below water is not really relevant except for pipe losses which increase the head slightly. The flow is 2000 liters/20 minutes = 100 l/min. This can be used with the head of 70m to determine the pipe restriction, which amounts to a pressure drop representing extra head added. It will indicate whether the pipe is too small (excessive head added) or whether the pipe is overkill (no head added). You can find on line calculators for this, e.g. search pipe resistance flow on line calculator. I am guessing a 2 inch pipe has little loss at this flow. This is the so called water power. It is the output power of the pump. The pump may only be 50% or so efficient, so the mechanical power delivered by the motor needs to be greater by this ratio. The electrical input power to the motor is greater again to allow for motor efficiency. This might be 60-90%. In practice the efficiency of pump and motor are determined from user manual or specification of the actual devices with the actual loads (head and flow).

Send your message to us

HY Series Chemical Submerged Pump(API 610)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords