Hot Rolled unequal Angle Steel for Transmission Towers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

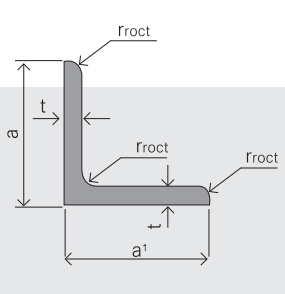

Specifications of Hot Rolled unequal Angle Steel for Transmission Towers

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as transport machinery, ships, industrial furnaces, reaction tower, container frame etc.

Packaging & Delivery of Hot Rolled unequal Angle Steel for insteel structrure

1. With bundles and load in container, or by bulk cargo, also we could do as customer's request.

- Q: How do steel angles perform in high-humidity environments?

- Due to their corrosion-resistant properties, steel angles exhibit excellent performance in high-humidity environments. While the air's moisture content often causes metals to rust and corrode, steel angles are specifically engineered to withstand these conditions. Typically manufactured using stainless steel or galvanized steel, both materials possess a protective layer that effectively hinders rust formation. Consequently, steel angles are exceptionally well-suited for utilization in regions with high humidity, such as coastal areas or industrial settings where moisture is abundant. Moreover, their durability and extended lifespan further contribute to their exceptional performance in high-humidity environments.

- Q: Can steel angles be used in mezzanine or raised platform construction?

- Mezzanine or raised platform construction can indeed incorporate steel angles. The strength and durability of steel angles make them a popular choice for structural supports in construction. These angles can serve as framing components, forming the framework of the mezzanine or raised platform. By providing stability and support, steel angles guarantee the structure's resilience and capacity to endure substantial loads. What's more, the versatility of steel angles stems from their ease of welding or bolting together, rendering them suitable for a wide range of construction projects.

- Q: How do you calculate the moment resistance of a steel angle?

- In order to determine the moment resistance of a steel angle, one must take into account the angle's geometry and material properties. The moment resistance refers to the angle's capacity to withstand bending forces. Initially, the section modulus must be calculated, which measures the shape's resistance to bending. The section modulus is obtained by dividing the angle's moment of inertia (I) by the distance from the shape's centroid to the farthest point (c). Subsequently, the yield strength of the steel angle needs to be determined. This is the point at which the material begins to permanently deform. The yield strength is typically provided by the manufacturer or can be acquired through material testing. Lastly, the moment resistance can be calculated by multiplying the section modulus (Z) by the yield strength (σ). This calculation yields the maximum moment that the steel angle can withstand before permanent deformation occurs. Moment Resistance = Z * σ It is important to note that this calculation assumes that the steel angle is solely subjected to bending. If there are additional factors present, such as axial or shear forces, further calculations or considerations may be necessary. Furthermore, it is always advisable to consult relevant design codes or engineering handbooks for more precise and detailed calculations.

- Q: What is the typical tolerance for steel angles?

- The specific application and industry standards determine the typical tolerance for steel angles. Generally, the industry standard allows for a tolerance of ±1/8 inch or ±3 millimeters. This means that the actual dimensions of the angle can differ by up to 1/8 inch or 3 millimeters from the specified dimensions. It is worth noting that these tolerances may differ depending on the grade of steel and the manufacturing process used. Consequently, it is vital to refer to the appropriate industry standards or specifications for the specific project in order to ascertain the precise tolerance requirements for steel angles in that particular application.

- Q: How do you calculate the compression capacity of a steel angle?

- To calculate the compression capacity of a steel angle, you need to consider the cross-sectional area of the angle and the material's yield strength. The compression capacity can be determined by multiplying the cross-sectional area of the angle by the yield strength of the steel.

- Q: What are the common methods of joining steel angles together?

- There are several common methods for joining steel angles together. 1. Welding: Welding is a popular method used to join steel angles together. It involves melting the edges of the angles and then allowing them to cool and solidify, creating a strong bond. Welding can be done using various techniques such as arc welding, MIG welding, or TIG welding. 2. Bolting: Bolting is another common method used to join steel angles. It involves using bolts, nuts, and washers to secure the angles together. This method allows for easy disassembly and reassembly if needed. Bolts are typically used in conjunction with gusset plates or brackets to provide additional strength and stability. 3. Riveting: Riveting is a traditional method of joining steel angles together. It involves using a rivet, which is a cylindrical metal pin, to hold the angles in place. The rivet is inserted into pre-drilled holes in the angles and then deformed on one end to create a head, securing the angles together. 4. Adhesive bonding: Adhesive bonding is a method that involves using a specialized adhesive to join steel angles together. The adhesive is applied between the angles, and then pressure is applied to ensure a strong bond. Adhesive bonding is often used in situations where a clean and aesthetically pleasing joint is desired. 5. Mechanical fasteners: Mechanical fasteners such as screws, nails, or self-tapping screws can also be used to join steel angles together. These fasteners are inserted into pre-drilled holes and provide a secure connection. However, they may not be as strong as other methods such as welding or bolting. It is important to consider the specific requirements of the application, such as the load-bearing capacity, aesthetics, and ease of disassembly, when choosing the appropriate method for joining steel angles together.

- Q: How do steel angles compare to other structural materials like wood or aluminum?

- Steel angles have distinct advantages over other structural materials like wood or aluminum. Firstly, steel angles are much stronger and more durable than wood, making them suitable for high-load bearing applications. Additionally, steel angles have excellent fire resistance compared to wood, making them a safer choice in construction. When compared to aluminum, steel angles offer superior strength and rigidity, making them more suitable for heavy-duty applications. Moreover, steel angles are more cost-effective and have a longer lifespan than aluminum, making them a preferred choice for many construction projects.

- Q: Can steel angles be used for temporary or removable structures?

- Steel angles, known for their versatility, find frequent use in construction for a range of purposes, including temporary or removable structures. They serve as framing components in scaffolding, support structures, and temporary partitions. Thanks to their ability to provide structural support and stability, steel angles prove ideal for temporary or removable structures that demand strength and durability. Moreover, their straightforward assembly and disassembly facilitate convenient installation and removal of such structures.

- Q: Are steel angles resistant to earthquakes?

- Yes, steel angles are resistant to earthquakes. Steel is a strong and durable material that can withstand the forces generated during seismic events. The use of steel angles in construction provides stability and structural integrity, making them a reliable choice for earthquake-resistant buildings.

- Q: What is the maximum length for a steel angle bracket?

- The maximum length for a steel angle bracket can vary depending on the manufacturer and the specific design of the bracket. However, in general, steel angle brackets are commonly available in lengths ranging from 1 inch to 8 feet or more. It's important to note that longer brackets may be more prone to bending or flexing under heavy loads, so it's essential to consider the intended application and weight-bearing requirements when selecting the appropriate length for a steel angle bracket. Additionally, consulting the manufacturer's guidelines and specifications is recommended to ensure the bracket's maximum length is not exceeded, as this could compromise its structural integrity.

Send your message to us

Hot Rolled unequal Angle Steel for Transmission Towers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords