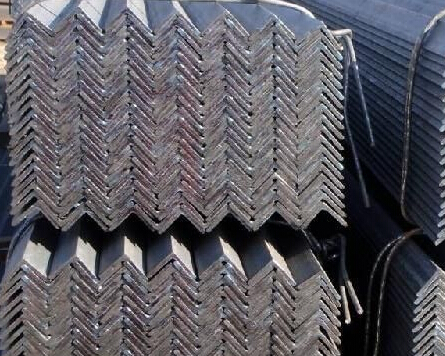

Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Equal Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the standard dimensions for unequal leg steel angles?

- The standard dimensions for unequal leg steel angles can vary depending on the specific requirements of a project or the country in which they are being used. However, there are generally accepted standard dimensions that are commonly used in various industries. In the United States, the standard dimensions for unequal leg steel angles are typically defined by the American Society for Testing and Materials (ASTM). According to ASTM A6/A6M, the standard specification for general requirements for rolled structural steel bars, plates, shapes, and sheet piling, unequal leg steel angles are designated by their nominal size and weight per foot. For example, a commonly used unequal leg steel angle would have a nominal size of 2 x 1-1/2 inches and a weight per foot of 2.71 pounds. Another common size would be 3 x 2 inches with a weight per foot of 4.23 pounds. These dimensions may vary depending on the specific requirements of a project, but they serve as a general guide for the standard dimensions of unequal leg steel angles.

- Q: What are the different tolerances for steel angles?

- The different tolerances for steel angles can vary depending on the specific industry standards and requirements. Generally, tolerances for steel angles may include measurements for dimensions such as length, width, thickness, and straightness. These tolerances ensure that the steel angles meet the desired specifications and can be properly utilized in various applications.

- Q: What are the common applications of steel angles?

- Steel angles find extensive use in a multitude of applications owing to their adaptability and robustness. Some prevalent applications of steel angles encompass: 1. Supporting structures: Steel angles are frequently employed as integral components in the construction of buildings and bridges, providing the required fortitude and stability. They serve as beams, columns, and braces, bolstering the structure. 2. Construction: Steel angles play a crucial role in construction endeavors, facilitating the creation of frameworks, supports, and reinforcements. They are adept at forming wall corners, bolstering roof trusses, and enhancing the durability of concrete structures. 3. Machinery and equipment: In the manufacturing of machinery and equipment, steel angles are extensively employed as brackets, frames, and supports for various components. Their utilization ensures stability and structural integrity within these machines. 4. Industrial shelving and racks: Industrial shelving units and racks are frequently constructed using steel angles. These angles provide a robust and dependable structure capable of accommodating heavy items while optimizing storage space. 5. Agricultural equipment: Steel angles are integral to the fabrication of agricultural machinery and equipment, often serving as frames, supports, and brackets for farm implements like plows, cultivators, and harvesters. 6. Fencing and barriers: Steel angles find application in the construction of fences, barriers, and handrails, where their strength and durability are paramount. These angles imbue the structures with the resilience to endure harsh weather conditions and offer enhanced security. 7. Transportation: Vehicles and transportation equipment rely on steel angles during their construction. These angles can be found in truck beds, trailers, and railings, providing the necessary strength and stability for the safe transportation of goods and passengers. 8. Decorative and architectural applications: Steel angles are often utilized for decorative and architectural purposes. They seamlessly integrate into building facades, staircases, and ornamental metalwork, imparting a contemporary and sleek aesthetic while providing structural support. In conclusion, the versatility, durability, and strength of steel angles render them indispensable across a vast array of industries, serving a multitude of purposes.

- Q: How do you determine the required angle thickness for a specific application?

- To determine the necessary thickness of an angle for a particular application, multiple factors must be taken into account. First and foremost, one must understand the load or force that will be placed on the angle. This can be achieved by analyzing the specific application and estimating the weight or pressure that will be exerted on the angle. Next, the material of the angle must be considered. Different materials possess varying strength properties, and their ability to withstand the applied load will differ accordingly. It is crucial to select a material that possesses the necessary strength and durability for the application at hand. Alongside this, the length of the angle and the distance between its supports should also be considered. Longer angles or greater distances between supports may necessitate thicker angles to prevent buckling or bending when subjected to the applied load. Furthermore, environmental factors like temperature, humidity, or corrosive substances may impact the required thickness of the angle. For example, in corrosive environments, a thicker angle may be essential to ensure its longevity and structural integrity. Finally, it is imperative to consult applicable building codes, regulations, or industry standards to ensure compliance and safety. These guidelines often provide specific recommendations or requirements for angle thickness based on the intended application. In conclusion, determining the required angle thickness for a specific application entails analyzing the load, material strength, length, support distance, environmental factors, and relevant regulations. Proper consideration of these factors will help guarantee that the angle can withstand the applied load and provide a safe and durable solution for the given application.

- Q: How do steel angles differ from other structural shapes?

- Steel angles differ from other structural shapes in several ways. Firstly, steel angles have a distinct L-shaped cross-section, with two perpendicular flanges and a central web connecting them. This unique shape provides the angle with exceptional strength and load-bearing capacity, making it suitable for various structural applications. Secondly, steel angles are highly versatile and can be used in a wide range of construction projects. They can be easily welded, bolted, or screwed together to create complex structures such as frames, supports, and bracings. This flexibility makes them a preferred choice for engineers and architects. Moreover, steel angles are available in different sizes and thicknesses, allowing for customization based on specific project requirements. This variety in dimensions makes it easier to achieve the desired strength and stability in structural designs. Additionally, steel angles offer cost-effective solutions compared to some other structural shapes. Their efficient use of materials and manufacturing processes make them relatively affordable while still maintaining their durability and functionality. Lastly, steel angles can withstand significant loads and stresses, making them ideal for applications where structural integrity is crucial. Their ability to distribute weight evenly across the flanges and web ensures stability and prevents deformation under heavy loads. In summary, steel angles are unique structural shapes that provide strength, versatility, customizability, cost-effectiveness, and durability. These features make them an excellent choice for various construction projects, setting them apart from other structural shapes.

- Q: How do you calculate the bending stress in a steel angle?

- In order to determine the bending stress in a steel angle, one must have a grasp of the fundamentals of bending moment and the moment of inertia of the angle. Firstly, the bending moment acting on the steel angle needs to be determined. This can be achieved by considering the applied load or force and its distance from the point of rotation. The bending moment is obtained by multiplying the applied load by the distance between the point of rotation and the line of action of the force. Next, the moment of inertia of the steel angle needs to be established. The moment of inertia measures an object's resistance to changes in its rotational motion and is dependent on its shape and size. For a steel angle, the moment of inertia can be calculated using the appropriate formula for its specific cross-sectional shape. Once the bending moment and moment of inertia have been determined, the bending stress can be calculated using the following formula: Bending Stress = (Bending Moment * Distance from Neutral Axis) / Moment of Inertia The bending stress denotes the internal resistance within the steel angle to the bending moment and is typically expressed in units of force per unit area, such as pounds per square inch (psi) or newtons per square meter (Pa). It is important to note that the calculation of bending stress assumes the steel angle behaves elastically, meaning it does not experience excessive deformation or permanent damage. If the applied bending moment exceeds the elastic limit of the steel angle, plastic deformation or failure may occur, necessitating the use of a different analysis method.

- Q: What are the different packaging options for steel angles?

- The customer's specific needs and transportation method determine the various packaging options available for steel angles. Common options include: 1. Bundles: Steel angles can be bundled together using steel straps or wires. This option is suitable for larger quantities and provides stability and ease of handling. 2. Pallets: Steel angles can be placed on wooden or plastic platforms for easy transportation and storage. They are secured to the pallet using straps or stretch wrap. 3. Crates: Wooden crates offer extra protection for steel angles, making them ideal for long-distance transportation or outdoor storage. 4. Steel Cages: Steel angles can be packaged in metal cages with open sides for visibility and ventilation. This option is useful for bulk quantities. 5. Customized Packaging: Steel angles can be packaged according to specific customer requirements, such as adding protective materials like foam or plastic sheets to prevent damage during transit. It's important to consider factors like size, weight, transportation mode, and regulations when choosing a packaging option for steel angles.

- Q: How are steel angles protected against corrosion?

- Steel angles can be protected against corrosion through various methods. One common method is the application of a protective coating. This can be done by painting the steel angles with a corrosion-resistant paint or by applying a zinc coating through a process called galvanization. Galvanization involves immersing the steel angles in a bath of molten zinc, which forms a protective layer on the surface of the steel. Another method to protect steel angles against corrosion is by applying a corrosion inhibitor. This involves adding chemicals or compounds to the steel angles that prevent or slow down the corrosion process. Additionally, proper maintenance and regular inspections can help identify and address any signs of corrosion before it can cause significant damage.

- Q: How do you calculate the compression strength of a steel angle?

- To calculate the compression strength of a steel angle, you need to consider the cross-sectional area of the angle and the yield strength of the steel. The compression strength can be calculated by multiplying the cross-sectional area of the angle by the yield strength of the steel.

- Q: How do you determine the required thickness of a steel angle for a specific application?

- To determine the required thickness of a steel angle for a specific application, several factors need to be considered. Firstly, it is essential to determine the load or weight that the steel angle will be subjected to. This includes both the dead load (the weight of the steel angle itself) as well as any live loads (external forces or loads applied to the angle). Next, the span or distance between supports needs to be determined. The greater the span, the higher the bending moment and deflection that the steel angle will experience. Once the load and span are known, it is necessary to calculate the maximum allowable stress or bending moment that the steel angle can withstand. This is typically done using engineering formulas or structural analysis software. The maximum allowable stress is determined based on the steel's yield strength and safety factors. Using the maximum allowable stress and the bending moment, the required section modulus of the steel angle can be calculated. The section modulus is a measure of the angle's resistance to bending and is directly related to its thickness. Finally, the required thickness of the steel angle can be determined by selecting a standard angle size that has a section modulus equal to or greater than the calculated value. It is crucial to note that other considerations, such as corrosion protection, fire resistance, and aesthetics, may also influence the selection of the steel angle thickness. Therefore, consulting structural engineers or following relevant building codes and standards is highly recommended to ensure the safety and performance of the steel angle in a specific application.

Send your message to us

Hot Rolled Equal Angle Steel with Standards:GB,ASTM,BS,AISI,DIN,JIS

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords