Hot Rolled unequal Angle Steel for insteel structrure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

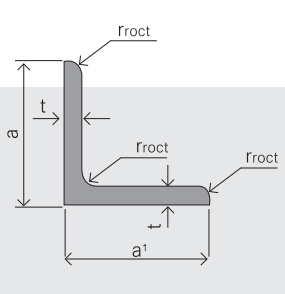

Specifications of Hot Rolled unequal Angle Steel for insteel structrure

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

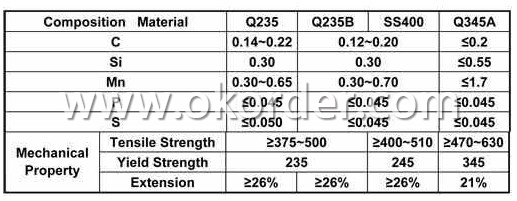

6. Material details:

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as roof beams, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Hot Rolled unequal Angle Steel for insteel structrure

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 30MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

- Q: How do you cut steel angles?

- Steel angles can be cut using various methods such as using a metal-cutting saw, an angle grinder with a cutting disc, or a plasma cutter. It is important to ensure proper safety precautions, use appropriate tools, and follow the manufacturer's instructions for the specific cutting method being used.

- Q: Can steel angles be used for structural applications?

- Indeed, structural applications can make use of steel angles. Due to their strength, durability, and versatility, steel angles are frequently employed in construction and engineering endeavors. The convenience of welding, bolting, or otherwise connecting them to other steel components makes them particularly valuable for providing structural support and stability. Frames, supports, braces, and reinforcements often incorporate steel angles. Moreover, their shape and design enable efficient load-bearing capabilities, rendering them suitable for a wide range of structural applications including bridges, buildings, towers, and industrial structures. In summary, steel angles present a dependable and budget-friendly option for structural applications.

- Q: Can steel angles be used for machine guards?

- Yes, steel angles can be used for machine guards. Steel angles are commonly used in industrial settings for their strength and durability, making them an ideal choice for machine guards that need to provide protection and withstand impact.

- Q: Can steel angles be used for storage racks?

- Certainly, storage racks can indeed be constructed using steel angles. Due to their exceptional strength and durability, steel angles find frequent usage within the construction industry. They possess the versatility to be effortlessly molded into numerous configurations, including those required for designing storage racks. These angles offer structural reinforcement and stability, rendering them an optimal choice for accommodating heavy items. Moreover, their resistance to corrosion becomes paramount in upholding the long-term robustness of the storage racks. All in all, steel angles serve as a dependable and widely employed material for fabricating storage racks.

- Q: Can steel angles be used to create decorative elements in architecture?

- Yes, steel angles can definitely be used to create decorative elements in architecture. These versatile structural components can be bent or shaped into various angles and forms, allowing architects and designers to incorporate them into the overall aesthetic of a building. From ornamental railings and window frames to decorative beams and columns, steel angles offer both strength and design possibilities, making them an ideal choice for decorative elements in architecture.

- Q: How do you calculate the stability of a steel angle column?

- To calculate the stability of a steel angle column, a few key factors need to be considered. Firstly, the slenderness ratio of the column, which is the ratio of its effective length to its least radius of gyration, must be determined. This can be calculated using the formula: Slenderness ratio = (Effective length of column) / (Least radius of gyration) The least radius of gyration can be calculated using the dimensions of the angle section. For a steel angle, the least radius of gyration can be approximated as the average of the two legs of the angle section divided by the square root of 3. Once the slenderness ratio is determined, it is important to check whether the column is long or short. If the slenderness ratio is less than a critical value, typically around 50 for an angle column, it is considered short and the stability is primarily governed by its strength. In this case, the column can be designed based on its capacity to resist axial compression and flexural buckling. However, if the slenderness ratio exceeds the critical value, the column is considered long and its stability is primarily governed by its ability to resist lateral-torsional buckling. In such cases, additional calculations and considerations must be made to ensure the column's stability. For long angle columns, the critical load at which lateral-torsional buckling may occur can be calculated using various formulas and methods, such as the Euler formula, the Perry-Robertson formula, or finite element analysis. These calculations take into account various parameters such as the column's moment of inertia, modulus of elasticity, and the length of the column. It is important to note that stability calculations for steel angle columns can be complex and require expertise in structural engineering. It is recommended to consult with a qualified professional or refer to relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, for accurate and reliable calculations.

- Q: Can steel angles be used for support structures in sports arenas or stadiums?

- Yes, steel angles can be used for support structures in sports arenas or stadiums. Steel angles are commonly used in construction due to their strength, durability, and versatility. They are particularly suitable for support structures as they can withstand heavy loads and provide stability. In sports arenas or stadiums, steel angles can be used for various purposes such as supporting the roof, creating seating platforms, constructing staircases, and forming the framework for walls and partitions. The flexibility of steel angles allows architects and engineers to design custom support structures that meet the specific requirements of each sports arena or stadium. Furthermore, steel angles can be easily fabricated and joined, making them ideal for the construction of complex support systems. Their ability to resist bending, twisting, and compression ensures the overall stability and safety of the structure. Moreover, steel is a sustainable material that is 100% recyclable. This makes it an environmentally friendly choice for sports arenas or stadiums. By using steel angles for support structures, the construction industry can contribute to reducing carbon emissions and promoting a more sustainable future. Overall, steel angles are a reliable and efficient choice for support structures in sports arenas or stadiums. Their strength, durability, versatility, and sustainability make them an excellent option for ensuring the safety and stability of these large-scale structures.

- Q: What is the maximum allowable bearing stress for a steel angle?

- The maximum allowable bearing stress for a steel angle depends on various factors such as the specific grade of steel, the angle's dimensions, and the application requirements. It is essential to consult relevant design codes, standards, or engineering references for accurate and up-to-date information on the maximum allowable bearing stress for a steel angle in a specific context.

- Q: Are steel angles suitable for agricultural applications?

- Indeed, steel angles prove to be apt for agricultural applications. These multifunctional and long-lasting steel angles are well-suited for a range of agricultural needs. They can be employed to fashion robust frameworks for greenhouses, barns, and storage structures. By delivering exceptional structural reinforcement and enduring the weight of hefty burdens, steel angles are well-matched for erecting sturdy barriers, gates, and enclosures for livestock. Moreover, as steel angles are resistant to corrosion, they prove indispensable in agricultural settings that frequently encounter dampness and chemicals. The reliability of steel angles, owing to their adaptability and durability, renders them an optimal choice for agricultural purposes.

- Q: Are steel angles resistant to earthquakes?

- Seismic-resistant construction can be achieved by utilizing steel angles, which possess high strength and ductility, making them suitable for this purpose. Often referred to as steel L-shaped beams, these steel angles are commonly employed in structural applications to provide support and reinforcement. During an earthquake, the utilization of steel angles aids in the even distribution of seismic forces throughout the structure, thereby reducing the occurrence of concentrated stress points. The L-shape design of these steel angles allows them to effectively resist bending and twisting forces, which are frequently encountered during seismic events. Moreover, steel angles can be interconnected and welded together to establish a rigid frame system, thereby enhancing their capability to withstand seismic forces. Such a system effectively absorbs and dissipates energy resulting from vibrations caused by earthquakes, ultimately minimizing any potential damage inflicted upon the structure. Nevertheless, it is crucial to acknowledge that the overall seismic resistance of a structure is contingent upon several factors, including its design, construction methods, and adherence to building codes and regulations. While steel angles alone cannot ensure complete protection against earthquakes, their integration into a well-designed seismic-resistant system significantly augments the structure's capacity to withstand seismic forces.

Send your message to us

Hot Rolled unequal Angle Steel for insteel structrure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords