Hot Rolled unequal Angle Steel for instruction building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

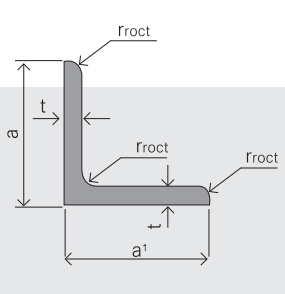

Specifications of Hot Rolled unequal Angle Steel for instruction building

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

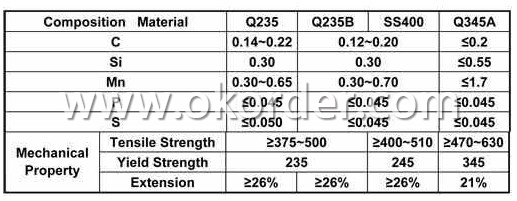

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).35% T/T prepaid and the balance against the copy of B/L.

3).35% T/T prepaid and the balance against L/C

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

6. Material details:

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Hot Rolled unequal Angle Steel for instruction building

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 30MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

- Q: Can steel angles be used in marine applications?

- Yes, steel angles can be used in marine applications. Steel angles are commonly used in the construction of ships, offshore platforms, and other marine structures due to their high strength and durability. They provide structural support and help distribute the weight and stress of the marine environment. Steel angles are resistant to corrosion, especially when coated with protective coatings or galvanized. However, it is important to select the appropriate grade of steel angle that is specifically designed for marine applications to ensure optimal performance and longevity in harsh saltwater environments.

- Q: Can steel angles be used for pipe supports or hangers?

- Yes, steel angles can be used for pipe supports or hangers. Steel angles provide structural support and stability, making them suitable for holding and securing pipes in various applications.

- Q: What are the different methods of fire protection for steel angles?

- There are several methods of fire protection for steel angles, including the use of fire-resistant coatings, intumescent paint, encasement with gypsum boards, and the application of fire-resistant sprays. These methods aim to slow down the heating of steel angles during a fire, allowing more time for evacuation and firefighting efforts.

- Q: What are the different methods of surface finishing for steel angles?

- Steel angles can be finished using various methods, each with its own advantages and considerations. Painting, galvanizing, powder coating, and shot blasting are the most commonly used methods. When it comes to surface finishing steel angles, painting is a popular choice. It not only protects against corrosion but also adds an appealing look. Typically, the angle is cleaned and primed before multiple coats of paint are applied. This method allows for a wide range of colors and easy touch-ups in case of damage. Galvanizing, on the other hand, involves coating the steel angle with zinc to safeguard it from corrosion. This method is particularly effective in harsh environments where moisture or chemicals may be present. The most common technique is hot-dip galvanizing, wherein the angle is immersed in molten zinc. This creates a durable finish that requires minimal maintenance. Another widely used method is powder coating, which entails applying a dry powder to the angle and then curing it with heat. This forms a protective layer that offers excellent durability and resistance to corrosion, chemicals, and UV rays. Powder coating also provides a smooth and consistent finish, with a wide array of color options. For a mechanical surface finishing approach, shot blasting is employed. This method involves blasting the steel angle with high-speed abrasive particles to remove rust, mill scale, or other contaminants. It results in a clean and smooth finish while creating a rough texture that enhances paint adhesion. Shot blasting is often used as a pre-treatment before painting or powder coating. When selecting a surface finishing method for steel angles, it is crucial to consider the specific requirements of their application. Factors such as the environment, expected lifespan, aesthetic preferences, and budget should all be taken into account. Seeking guidance from professionals or the steel manufacturer can help determine the most suitable surface finishing method for steel angles in a given situation.

- Q: Can steel angles be used in high-temperature applications?

- Yes, steel angles can be used in high-temperature applications. Steel is a strong and versatile material that maintains its structural integrity even at high temperatures. However, it is important to consider the specific grade and alloy of steel being used, as some may have limitations on their maximum operating temperature. Additionally, factors such as the duration of exposure to high temperatures and the presence of other corrosive elements should be considered when determining the suitability of steel angles for a particular high-temperature application.

- Q: What are the different types of steel angles connections for roof trusses?

- There are several different types of steel angle connections that are commonly used for roof trusses. These connections are designed to provide strong and stable support for the trusses, ensuring the structural integrity of the roof. One common type of steel angle connection is the gusset plate connection. This involves using steel plates, typically in a triangular shape, to connect the various members of the truss at their intersection points. The gusset plates are usually welded or bolted to the steel angles to create a secure connection. Another type of steel angle connection is the angle cleat connection. In this type of connection, steel angles are used to connect the truss members using bolts or welding. The angles are typically bolted or welded to the top and bottom chords of the truss, providing additional strength and stability. A third type of steel angle connection is the angle clip connection. This involves using steel clips or brackets to connect the truss members at their intersection points. The clips are typically bolted or welded to the steel angles, creating a strong and secure connection. Finally, there is the angle bracket connection. This type of connection involves using steel brackets or brackets to connect the truss members. The brackets are typically bolted or welded to the steel angles, providing a reliable and sturdy connection. Overall, there are various types of steel angle connections that can be used for roof trusses, each offering different advantages and characteristics. The specific type of connection used will depend on factors such as the design requirements, load-bearing capacity, and construction methods.

- Q: What is the cost of steel angles compared to other structural materials?

- The cost of steel angles compared to other structural materials can vary depending on various factors such as market conditions, availability, and specific requirements. However, in general, steel angles tend to be a cost-effective option for structural applications. Compared to materials like concrete or timber, steel angles are often considered more affordable due to their relatively low production costs. Steel is a widely available material, and its production processes have been optimized over the years, resulting in competitive pricing. Additionally, steel angles offer excellent strength-to-weight ratio, allowing for lighter and more cost-efficient structural designs. When compared to other metals like aluminum or stainless steel, steel angles are typically more cost-effective. While aluminum and stainless steel offer certain advantages in terms of corrosion resistance or aesthetic appeal, they tend to be more expensive due to their production processes and material properties. It is important to note that the exact cost of steel angles can vary depending on the specific dimensions, quality, and quantity required. Prices may also fluctuate based on market conditions, such as changes in raw material costs or global supply and demand dynamics. Therefore, it is recommended to consult with suppliers or industry professionals to get accurate and up-to-date pricing information for steel angles.

- Q: Are steel angles suitable for manufacturing equipment enclosures?

- Yes, steel angles are suitable for manufacturing equipment enclosures. Steel angles provide excellent strength, durability, and stability, making them ideal for constructing sturdy enclosures to protect equipment. They are also versatile and can be easily welded or bolted together to form the desired shape and size for the enclosure. Additionally, steel angles can withstand various environmental conditions and offer protection against impacts and other potential hazards.

- Q: What are the different methods of surface cleaning for steel angles?

- Some different methods of surface cleaning for steel angles include mechanical cleaning through techniques like sandblasting or wire brushing, chemical cleaning using solvents or acids, and electrochemical cleaning through processes like electrolysis.

- Q: What are the common loadings or forces that steel angles are designed to withstand?

- Steel angles are widely utilized in different structural applications because of their versatility and strength. These angles are engineered to endure various loadings or forces, depending on the specific application. Some typical loadings that steel angles are engineered to tolerate include: 1. Compression: Steel angles have the ability to withstand compressive forces, which are forces that tend to compress or squeeze the material. They are frequently employed in columns or supports to bear the weight of a structure or to resist crushing loads. 2. Tension: Steel angles can also endure tensile forces, which are forces that stretch or pull the material. They are commonly used in tension members, like roof trusses or bridge supports, to resist pulling or stretching loads. 3. Bending: Steel angles are designed to resist bending forces, which occur when a material is subjected to a combination of tension and compression. They are commonly used in beams or braces to provide structural stability and prevent excessive deflection or bending. 4. Shear: Steel angles have the capacity to withstand shear forces, which occur when one section of a material is pushed in one direction and another section is pushed in the opposite direction. They are frequently employed in connections or joints to transfer loads between structural members and resist shearing forces. 5. Lateral loads: Steel angles are also engineered to withstand lateral loads, which are forces that act horizontally on a structure. These loads can be caused by wind, earthquakes, or other external factors. Steel angles are often utilized in bracing systems to provide lateral stability and prevent the structure from overturning or collapsing. It is important to note that the specific loadings and forces that steel angles are engineered to withstand may vary depending on the size, shape, and grade of the angle, as well as the specific design requirements of the application. Therefore, it is crucial to consult the appropriate design codes and engineering guidelines to ensure the proper selection and application of steel angles in a given structural design.

Send your message to us

Hot Rolled unequal Angle Steel for instruction building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords