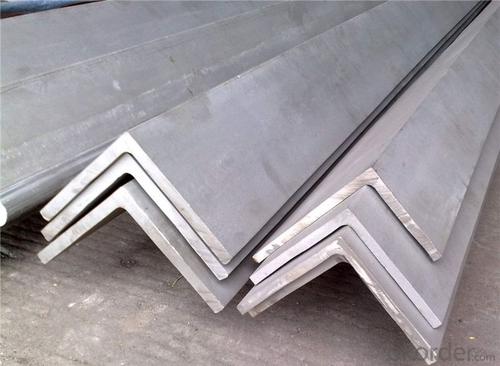

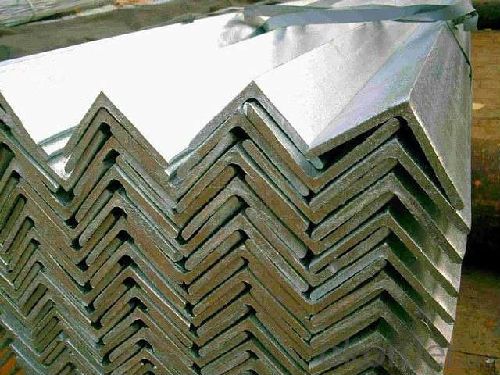

Hot rolled sheet Equal Steel Angle bar EN10056

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled sheet equal steel angle bar EN10056 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled sheet Equal Steel Angle bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's equal steel angle bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Images:

- Q: Can steel angles be used as supports for signage or lighting fixtures?

- Yes, steel angles can be used as supports for signage or lighting fixtures. Steel angles are commonly used in construction and can provide strong and sturdy support for various applications, including signage and lighting fixtures.

- Q: Can steel angles be used as handrails or guardrails?

- Yes, steel angles can be used as handrails or guardrails. Steel angles are often used in construction and industrial applications due to their strength and durability. When properly designed, fabricated, and installed, steel angles can provide a sturdy and reliable support system for handrails and guardrails. They can be welded or bolted to other structural elements to create a secure and safe railing system. Additionally, steel angles can be easily customized to meet specific design and aesthetic requirements. However, it is important to ensure that the steel angles used meet the necessary safety standards and building codes to ensure the protection and well-being of individuals using the handrails or guardrails.

- Q: What is the standard tolerance for steel angles?

- The standard tolerance for steel angles can vary depending on the specific requirements and industry standards. However, in general, the standard tolerance for steel angles is typically specified in terms of the permissible variation in dimensions such as length, width, and thickness. These tolerances ensure that the angles meet the necessary specifications and can be used effectively in various applications. It is important to consult the relevant industry standards or specifications, such as those provided by organizations like the American Society for Testing and Materials (ASTM) or the American Institute of Steel Construction (AISC), to determine the specific tolerance requirements for steel angles in a particular context.

- Q: How do steel angles perform under extreme temperatures?

- Steel angles typically perform well under extreme temperatures. Steel is known for its high thermal conductivity, which means it can quickly absorb and distribute heat. This property helps steel angles to withstand extreme temperatures without significant deformation or failure. However, it is important to note that the specific performance of steel angles under extreme temperatures can vary depending on factors such as the alloy composition and heat treatment of the steel. In some cases, steel angles may experience reduced strength or become more susceptible to corrosion at extremely high temperatures. It is recommended to consult with a materials engineer or refer to the manufacturer's specifications to determine the specific performance of steel angles under the desired extreme temperature conditions.

- Q: What are the design considerations for incorporating steel angles into a structure?

- When incorporating steel angles into a structure, several design considerations need to be taken into account. First and foremost, the load-bearing capacity of the steel angles must be carefully assessed to ensure they can support the intended loads. The dimensions and thickness of the angles should be determined based on the structural requirements and anticipated stress levels. Additionally, the connection details between the steel angles and other structural elements need to be carefully designed to ensure they provide sufficient strength and rigidity. Considerations should include the type of fasteners, welding techniques, and any additional reinforcement required to achieve the desired structural integrity. Furthermore, factors such as corrosion protection, fire resistance, and durability should also be considered during the design process. Appropriate measures should be taken to prevent rust and corrosion on the steel angles, such as applying protective coatings or using stainless steel. Fire-resistant coatings or fireproofing materials may also be necessary, depending on the building's fire safety requirements. Lastly, aesthetics and architectural considerations may come into play when incorporating steel angles into a structure. The design should take into account the desired visual appearance, whether the angles will be exposed or concealed, and how they will integrate with the overall architectural style. In conclusion, the design considerations for incorporating steel angles into a structure involve assessing load-bearing capacity, connection details, corrosion protection, fire resistance, durability, and aesthetic integration.

- Q: How do steel angles perform in corrosive gas or liquid environments?

- The strength and versatility of steel angles make them a popular choice for various structural applications. However, their performance in corrosive gas or liquid environments can be impacted by the grade of steel used and the concentration and nature of the corrosive substance. When exposed to corrosive gases or liquids, steel angles can undergo corrosion, leading to a gradual deterioration of their structural integrity. The extent of corrosion depends on factors such as exposure time, temperature, humidity, and the corrosiveness of the gas or liquid. To counteract the effects of corrosion, protective coatings can be applied to steel angles used in corrosive environments. Examples of common protective coatings include galvanization, which involves adding a layer of zinc to the steel surface, as well as epoxy or polyurethane coatings. These coatings create a barrier that prevents direct contact between the corrosive substance and the steel, thereby slowing down the corrosion process. However, it is important to acknowledge that even with protective coatings, steel angles may still experience some level of corrosion over time. The extent of corrosion will depend on the quality and durability of the coating, as well as the regular maintenance and inspection of the steel angles. In extremely aggressive or highly concentrated corrosive environments, steel angles may not be the most suitable choice. In such cases, alternative materials like stainless steel or corrosion-resistant alloys may be more appropriate. In conclusion, the performance of steel angles in corrosive gas or liquid environments is influenced by specific conditions and protective measures in place. Regular inspection, proper maintenance, and the use of suitable coatings are vital for ensuring the longevity and performance of steel angles in corrosive environments.

- Q: What are the maintenance requirements for steel angles?

- The maintenance requirements for steel angles can vary depending on the specific environment and conditions they are exposed to. However, there are some general guidelines to follow to ensure their longevity and functionality. Firstly, it is important to regularly inspect steel angles for any signs of damage or corrosion. This can be done by visually examining the angles and checking for any discoloration, rust, or surface irregularities. If any issues are detected, they should be addressed promptly to prevent further deterioration. Cleaning the steel angles on a regular basis is also essential. This can be done by using a mild detergent or soap solution and a soft cloth or sponge. Avoid using abrasive cleaners or tools that can scratch the surface of the angles. After cleaning, it is important to thoroughly rinse the angles with clean water and dry them completely to prevent moisture buildup. To protect steel angles from corrosion, applying a protective coating or paint is recommended. This can act as a barrier against moisture and other corrosive elements. It is important to choose a coating or paint that is specifically designed for steel and suitable for the intended environment. Regular inspection and touch-up of the coating or paint may be necessary to maintain its effectiveness. Additionally, it is crucial to prevent prolonged exposure to harsh chemicals or corrosive substances that can damage the steel angles. If the angles are installed in an environment where they may come into contact with such substances, it is important to provide appropriate protective measures, such as using chemical-resistant coatings or barriers. Finally, it is advisable to follow any specific maintenance recommendations provided by the manufacturer or supplier of the steel angles. They may have additional guidelines or requirements based on the specific type or grade of steel used. By following these maintenance requirements, steel angles can remain in good condition, retain their structural integrity, and provide long-lasting performance.

- Q: How do you calculate the weight of a steel angle?

- To calculate the weight of a steel angle, you need to know the dimensions of the angle and the density of steel. The weight of an object can be calculated using the formula: Weight = Volume × Density For a steel angle, the volume can be calculated by multiplying the cross-sectional area of the angle by its length. The cross-sectional area of the angle can be found by multiplying the width of the angle by its height. Once you have the volume, you can multiply it by the density of steel to determine the weight. For example, let's say we have a steel angle with a width of 3 inches, a height of 3 inches, and a length of 6 feet. The density of steel is typically around 7850 kg/m³ or 0.2836 lb/in³. First, calculate the cross-sectional area: Area = width × height Area = 3 in × 3 in Area = 9 in² Next, calculate the volume: Volume = Area × length Volume = 9 in² × 6 ft × 12 in/ft Volume = 648 in³ Finally, calculate the weight: Weight = Volume × Density Weight = 648 in³ × 0.2836 lb/in³ Weight = 183.9828 lb Therefore, the weight of the steel angle would be approximately 183.98 pounds.

- Q: Can steel angles be used for manufacturing handrails?

- Yes, steel angles can be used for manufacturing handrails. Steel angles are often used in construction and fabrication due to their strength and durability. They can be easily shaped and welded to create a variety of structures, including handrails. The angular shape of steel angles provides stability and support, making them ideal for handrail applications. Additionally, steel angles can be galvanized or coated to enhance their corrosion resistance, ensuring the longevity and safety of the handrails.

- Q: Can steel angles be used for manufacturing window frames?

- Indeed, the utilization of steel angles is feasible for the production of window frames. Given their robustness, longevity, and versatility, steel angles are extensively employed in both construction and manufacturing. They furnish a robust structure for windows, capable of enduring the weight and force exerted by the window glass. The assembly of steel angles through welding, bolting, or screwing allows for the creation of a robust and steady window frame. Furthermore, steel angles can be tailored to meet precise design specifications, rendering them suitable for a wide array of window sizes and shapes. All in all, owing to their dependability, strength, and adaptability, steel angles are a favored option for the manufacturing of window frames.

Send your message to us

Hot rolled sheet Equal Steel Angle bar EN10056

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords