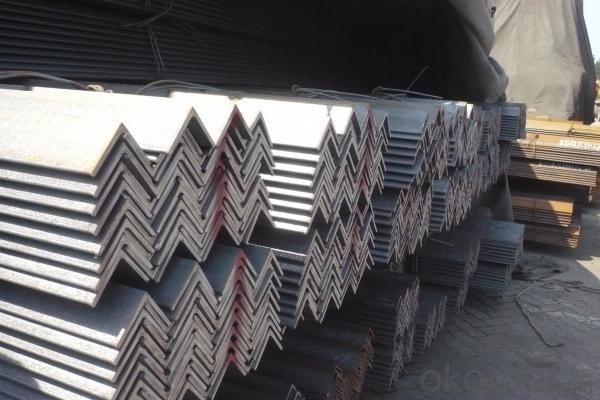

JIS SS400 Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25mts m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS SS400 Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Invoicing on theoretical weight or actual weight as customer request

3.Material: JIS G3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material Specifications:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

Usage & Applications JIS SS400 Angle Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of JIS SS400 Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of JIS SS400 Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be used for framing?

- Yes, steel angles can be used for framing in construction projects. Steel angles, also known as angle irons, are L-shaped metal profiles that offer excellent strength and durability. They are commonly used for framing applications due to their structural stability and ability to support heavy loads. Steel angles can be easily cut, welded, and bolted together to create sturdy frames for various structures, including buildings, bridges, and industrial facilities. They are often used as vertical or horizontal supports, bracing elements, or lintels to provide stability and structural integrity. Additionally, steel angles can be galvanized or coated to enhance their corrosion resistance, making them suitable for both indoor and outdoor framing applications. Overall, steel angles are a versatile and reliable choice for framing in construction projects.

- Q: How do steel angles perform in terms of thermal conductivity?

- Steel angles have relatively low thermal conductivity compared to other materials. This means that they are not as efficient in conducting heat as materials such as aluminum or copper. However, steel angles still have moderate thermal conductivity, which allows them to dissipate heat to some extent. This property can be advantageous in certain applications where heat transfer needs to be controlled or balanced. Overall, while steel angles may not have the highest thermal conductivity, they still offer sufficient performance for many structural and construction purposes.

- Q: How are steel angles different from steel channels?

- Structural steel shapes commonly used in construction and engineering projects include steel angles and steel channels. These shapes differ in both their form and structural characteristics. Steel angles possess an L-shaped cross-section, featuring two legs positioned at right angles to one another. The length of these legs can be equal or unequal, depending on the specific application. Steel angles are frequently employed to provide structural support in various scenarios, such as framing, bracing, and reinforcement. They play a vital role in construction projects, enhancing stability and strength. Conversely, steel channels possess a U-shaped cross-section, with two parallel flanges connected by a web. The flanges are oriented in the same direction, while the web serves as a connecting element. Steel channels are commonly utilized in load-bearing applications, including building frameworks, support beams, and infrastructure projects. These channels are designed to distribute weight evenly and ensure structural stability. Regarding their structural properties, steel angles are renowned for their high strength-to-weight ratio. This characteristic makes them suitable for applications requiring strength and durability. Steel angles can be easily welded, bolted, or riveted, contributing to their versatility and ease of handling. On the other hand, steel channels excel in load-bearing capabilities due to their U-shaped design. The parallel flanges enhance strength and stability, making them ideal for supporting heavy loads and resisting bending or twisting forces. Steel channels are also recognized for their resistance to warping and twisting, ensuring the integrity of the structure. In conclusion, steel angles and steel channels differ in terms of form and structural characteristics. Steel angles possess an L-shaped cross-section and are commonly used in framing and reinforcement, while steel channels possess a U-shaped cross-section and are employed in load-bearing applications. Understanding these disparities is crucial when selecting the appropriate structural steel shape for a construction or engineering project.

- Q: How does the weight of a steel angle affect its load-bearing capacity?

- The load-bearing capacity of a steel angle is directly impacted by its weight. Generally, a heavier steel angle possesses a greater load-bearing capacity compared to a lighter one. This is due to the weight of the angle contributing to its overall strength and stability. When a load is exerted on a steel angle, it generates both compressive and tensile forces within the material. The weight of the angle aids in evenly distributing these forces, minimizing the likelihood of deformation or failure. Moreover, a heavier steel angle typically signifies a higher density and a larger quantity of material utilized in its construction. Consequently, the angle can endure larger loads without experiencing significant deflection or structural damage. It is crucial to acknowledge that the load-bearing capacity of a steel angle is also influenced by additional factors such as its dimensions, material properties, and the type of connection employed. Nonetheless, the weight of the angle remains a vital consideration in determining its overall strength and ability to support loads.

- Q: What are the common surface treatments for steel angles?

- Different surface treatments are available for steel angles, depending on the desired application and level of corrosion resistance needed. Some commonly used surface treatments are: 1. Hot-dip galvanizing: To achieve excellent corrosion resistance, steel angles are submerged in molten zinc, which creates a protective layer on the surface. This treatment is commonly used for outdoor applications. 2. Powder coating: A dry powder is applied to the steel angles and then heated to form a durable and decorative coating. Powder coating provides good corrosion resistance and can be used indoors or outdoors. 3. Painting: Painting is a versatile and cost-effective option for treating steel angles. First, a rust-inhibiting primer is applied, followed by a suitable topcoat. While paint provides a decorative finish and some corrosion resistance, it may not be as long-lasting as other treatments. 4. Electroplating: This process involves depositing a thin layer of metal, like zinc or chrome, onto the steel angles using an electric current. Electroplating offers both corrosion resistance and aesthetic appeal, making it suitable for various applications. 5. Anodizing: Although primarily used for aluminum, anodizing can also be applied to steel angles. It involves creating an oxide layer on the metal surface, which enhances corrosion resistance and durability. Anodizing can also provide a decorative finish and is commonly used in architectural applications. It's important to consider factors such as the intended use, budget, and environmental conditions when selecting a surface treatment for steel angles. Seeking guidance from professionals or experts in the field can help determine the most suitable treatment for a specific application.

- Q: Can steel angles be used for sign supports?

- Yes, steel angles can be used for sign supports. Steel angles provide strength and stability, making them suitable for supporting signs of various sizes and weights. They are commonly used in the construction industry for a variety of structural applications, including sign supports. The angles can be easily welded or bolted together to create a sturdy framework for the signs. Additionally, steel angles are durable and resistant to environmental factors such as wind, rain, and corrosion, ensuring the longevity of the sign supports.

- Q: How do steel angles contribute to the stability of a structure?

- Steel angles contribute to the stability of a structure by providing additional strength and rigidity. They are commonly used to reinforce and support various components, such as beams and columns, by distributing the load and preventing buckling or bending. Their triangular shape allows for efficient weight distribution and helps resist lateral forces, enhancing the overall stability and structural integrity of the building.

- Q: What are the different types of steel angle connections used in seismic design?

- In seismic design, there are several types of steel angle connections commonly used. These connections are specifically designed to withstand the forces and movements experienced during seismic events. Some of the different types of steel angle connections used in seismic design include: 1. Bolted Flange Plate Connection: This type of connection involves bolting a steel plate to the flanges of two angle sections. It provides good resistance against lateral and vertical forces and can accommodate rotational movements. 2. Welded Flange Plate Connection: Similar to the bolted flange plate connection, this connection involves welding a steel plate to the flanges of two angle sections. It offers high strength and stiffness, but it is less ductile compared to the bolted version. 3. Extended Single Plate Connection: This connection is created by extending a single plate beyond the flanges of two angle sections and then welding it to both the flanges. It provides good resistance against lateral and vertical forces and can accommodate some degree of rotation. 4. Double Angle Connection: In this connection, two angle sections are connected together using bolts or welds. It offers high strength and stiffness and can resist lateral and vertical forces effectively. 5. Diagonal Brace Connection: This type of connection involves connecting diagonal braces to the flanges of two angle sections. It provides enhanced resistance against lateral forces and can effectively control building sway during seismic events. 6. Gusset Plate Connection: This connection involves using a gusset plate to connect two or more angle sections together. It provides good strength and stiffness and can resist lateral and vertical forces effectively. Each of these steel angle connections has its own advantages and disadvantages, and the choice of which connection to use depends on factors such as the structural design requirements, loadings, and the level of seismic activity in the region. It is important to carefully consider these factors and consult with structural engineers to ensure the appropriate connection type is used for a seismic design project.

- Q: Can steel angles be cut to custom lengths?

- Yes, steel angles can be cut to custom lengths. Steel angles, also known as angle irons, are versatile structural components commonly used in construction and manufacturing. They are available in various standard sizes, but they can also be customized to meet specific length requirements. This can be achieved by using cutting tools such as saws or shears to trim the steel angle to the desired length. The ability to cut steel angles to custom lengths makes them suitable for a wide range of applications, as they can be tailored to fit specific design needs.

- Q: What is the weight of a steel angle?

- The weight of a steel angle can vary depending on its dimensions and composition.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

JIS SS400 Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25mts m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords